Rubber band vulcanization device with rapid cooling function

A rapid cooling and rubber band technology, which is applied in the field of rubber band processing equipment, can solve the problems of incomplete vulcanization, difficulty in ensuring the stacking effect of rubber bands, and inability to guarantee the cooling effect of rubber band vulcanization, so as to improve the vulcanization effect and ensure the vulcanization quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

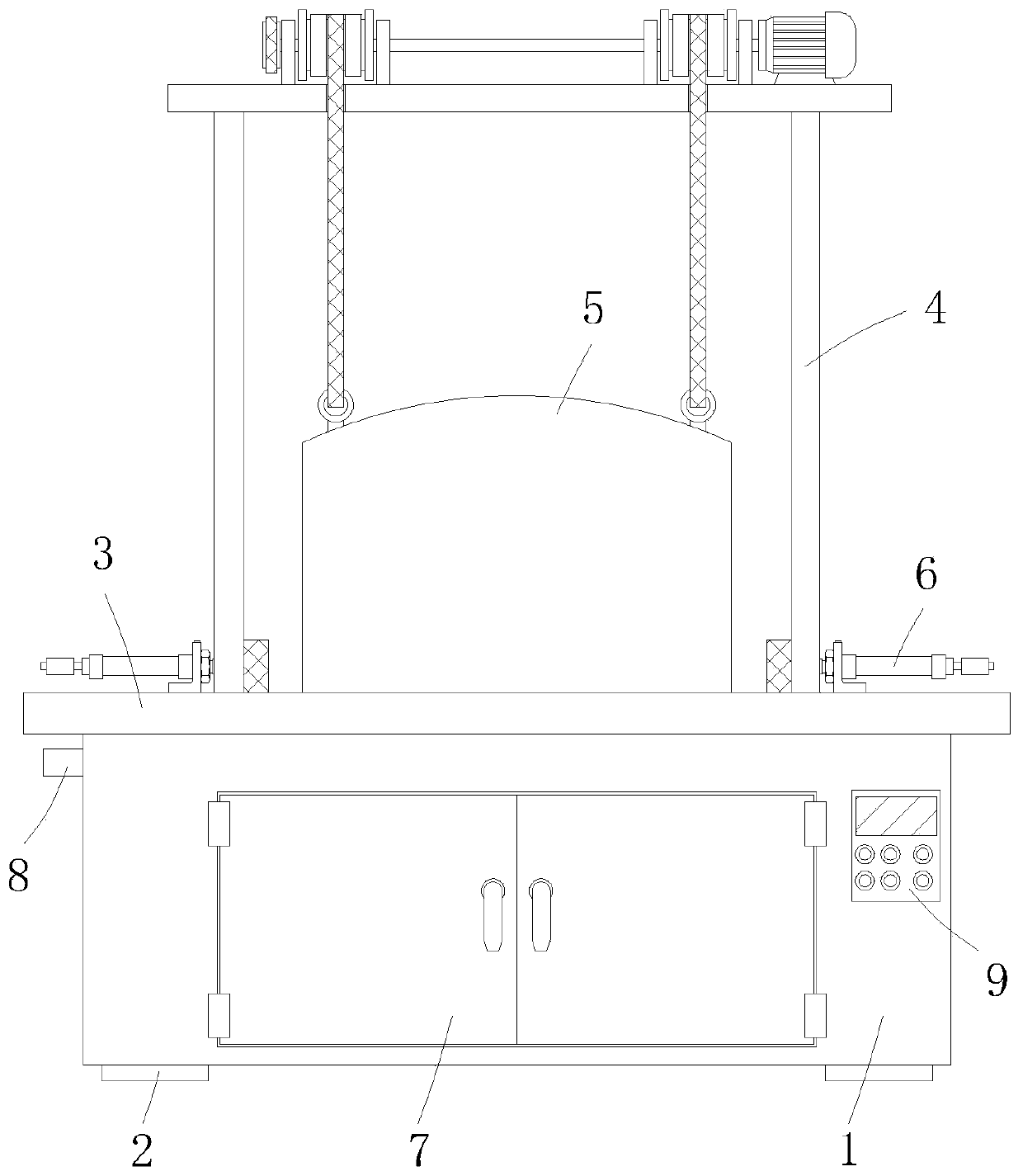

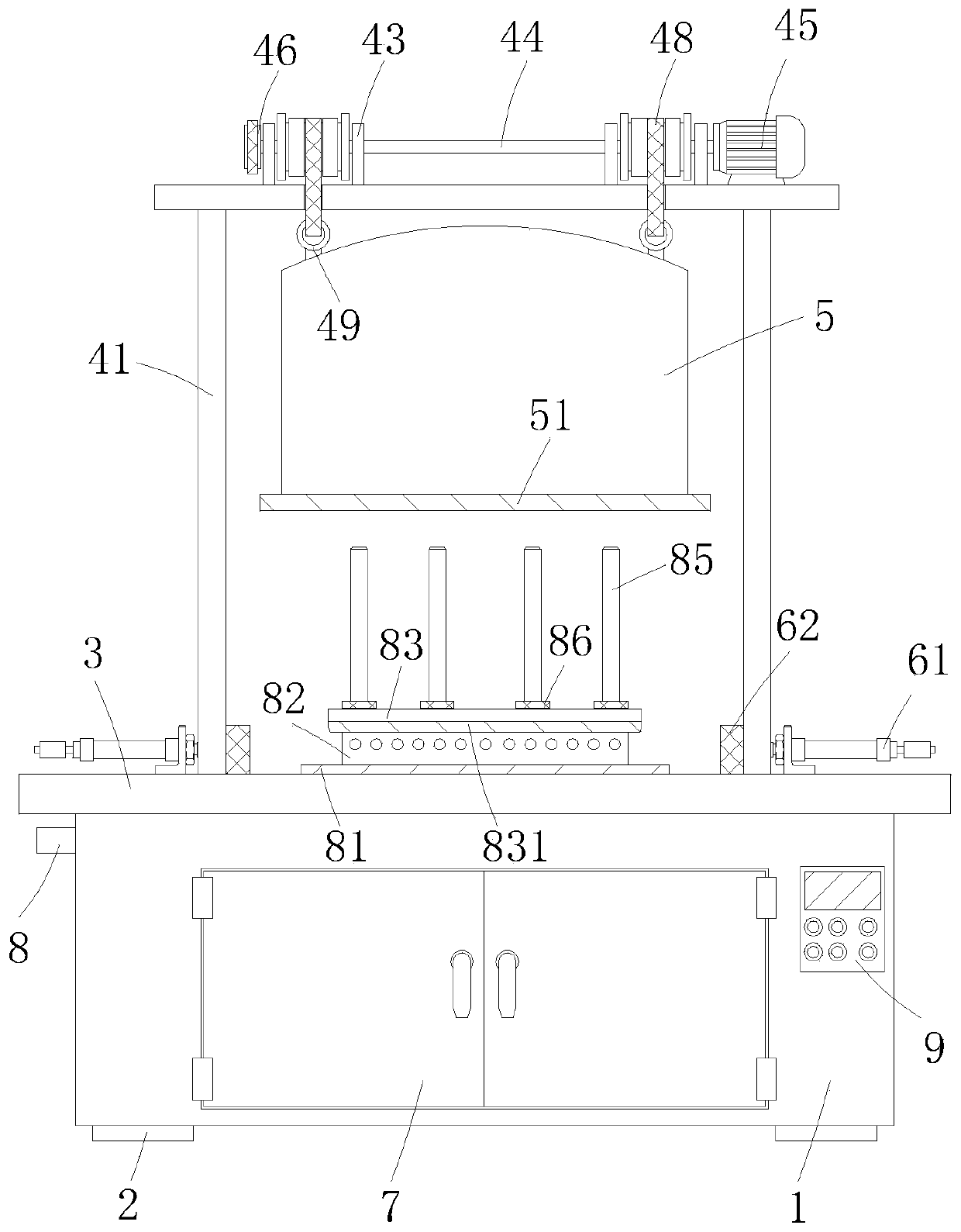

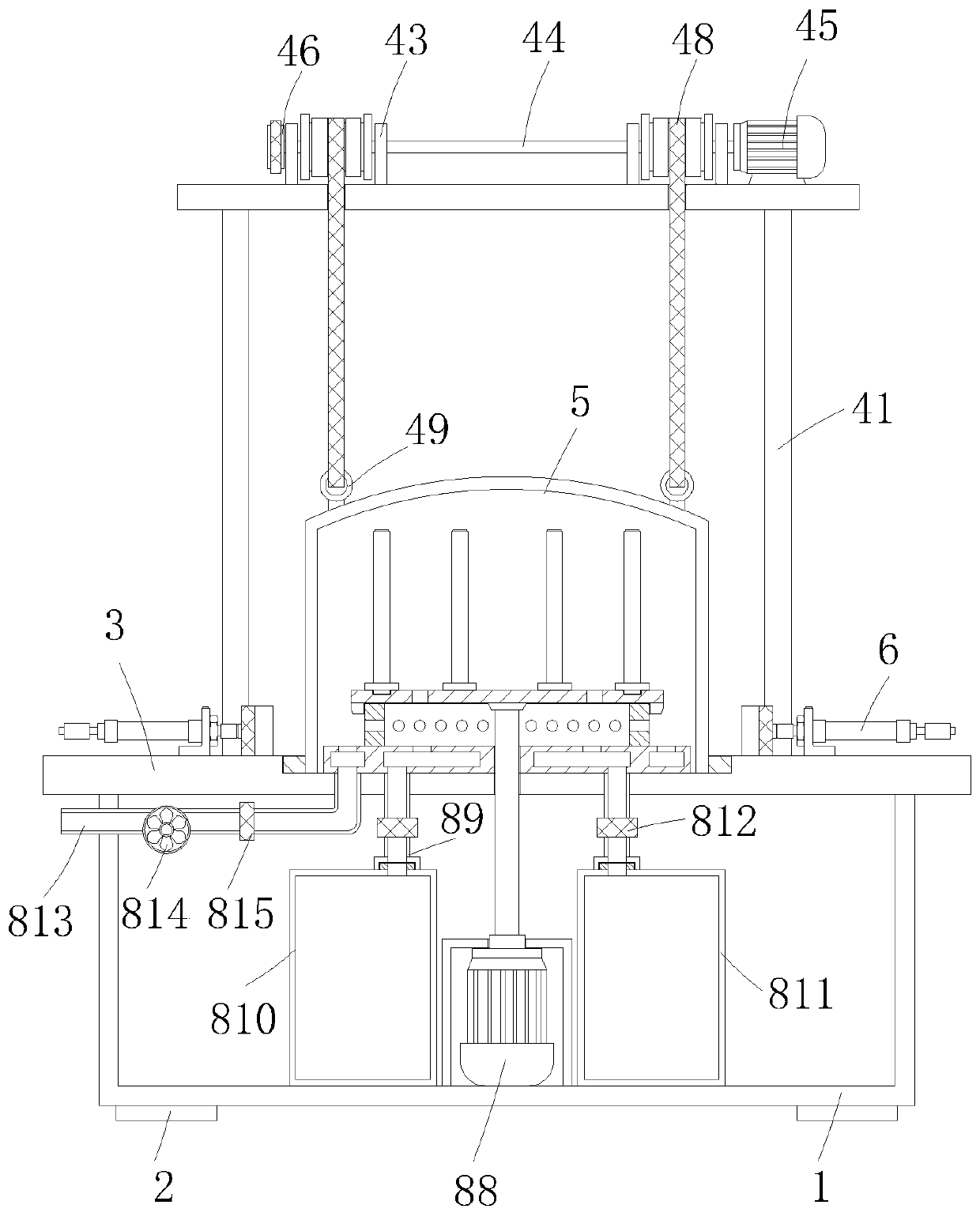

[0039] A rubber band vulcanizing device with rapid cooling function, comprising a base box 1 and a plurality of support feet 2 installed at the lower end of the base box 1, a processing table 3 is installed horizontally on the upper end of the base box 1, and a processing table 3 is provided on the upper end of the processing table 3 The vulcanization bottom tank, and the vulcanization mechanism 8 is arranged in the vulcanization bottom tank, and the top of the vulcanization bottom tank is matched with an inverted bowl-shaped vulcanization shell cover 5, and the vulcanization shell cover 5 goes down to cooperate with the vulcanization bottom tank to form a complete vulcanization chamber. For the vulcanization of rubber bands, it can be understood that the lower end of the vulcanization shell upper cover 5 can be provided with a sealing rubber ring to ensure the sealing of the vulcanization chamber;

[0040] In this example, if Figure 2-6 As shown, the vulcanization mechanism ...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that, as Figure 1-3 As shown in and 7, a lifting mechanism 4 is also provided above the vulcanization shell upper cover 5, the lifting mechanism 4 includes a frame 41 installed on the upper end of the processing table 3, and the top wall of the frame 41 is distributed in a matrix with four Winch 43, winch 43 is installed on the top wall of frame 41 by turret 42, is positioned at two winches 43 on the same side and is coaxially connected in series by turning bar 44, and one end of two turning bars 44 is all equipped with drive chain wheel 46, And two transmission sprockets 46 are connected by chain 47 transmissions, and the shaft end of one of them rotating rod 44 is installed on the output end of servomotor 45, and servomotor 45 is fixedly installed on the top wall of frame 41, winds on winch 43 There are ropes 48, and the lower ends of the four ropes 48 extend to the inside of the frame 41 and are connected wi...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that, as shown in Figures 3 and 8, a positioning mechanism 6 is symmetrically provided on both sides of the vulcanization bottom groove, and the positioning mechanism 6 includes a positioning block 62 that is symmetrically slidably installed on the upper end of the processing table 3 , and the opposite side of the positioning block 62 is installed on the telescopic end of the positioning cylinder 61, and the positioning cylinder 61 is installed on the upper end of the processing table 3 through a bracket.

[0056] In this example, if Figure 3-4 As shown, the lower edge of the upper cover 5 of the vulcanization shell is integrally formed with an annular rib 51 outward, and a positioning groove is provided at the position below the vulcanized bottom groove matching the annular rib 51 .

[0057] According to the rubber band vulcanizing device with rapid cooling function of the above-mentioned embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com