An aluminum alloy die-casting mold with rapid cooling and cooling function

A rapid cooling and die-casting mold technology, applied in the field of die-casting molds, can solve the problems of mold users such as economic losses, lower casting production efficiency, insufficient cooling capacity, etc., achieve good results, ensure quality, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

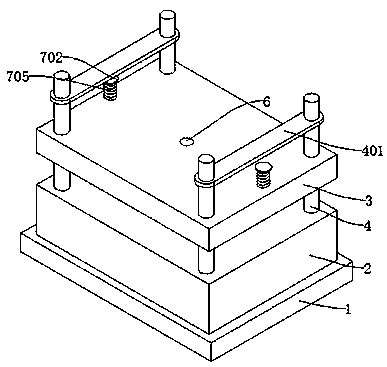

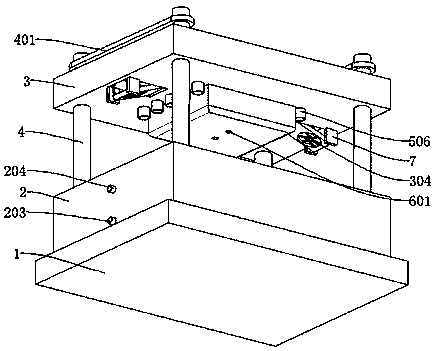

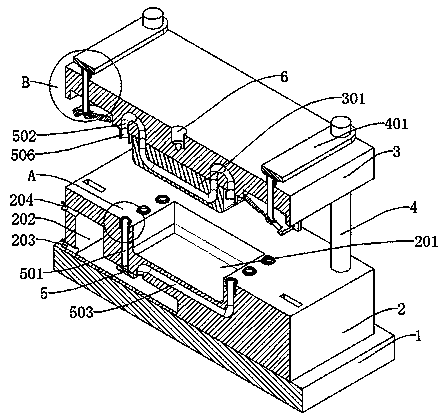

[0031] refer to Figure 1-6 , an aluminum alloy die-casting mold with rapid cooling and cooling functions, comprising a bottom plate 1, a lower template 2 and an upper template 301, the lower template 2 is connected to the bottom plate 1, and the lower template 2 is connected to a limit rod 4, and the limit rod 4 is far away from the One end of the lower formwork 2 is connected with a slide plate 3, the slide plate 3 is slidably connected to the limit rod 4, the upper formwork 301 is connected to the bottom of the slide plate 3, and the lower formwork 2 is dug with a mold groove 201 matching the upper formwork 301, and the lower formwork 2, a water tank 202, a first cooling water channel 501 and a third cooling water channel 503 are excavated respectively. The end away from the water tank 202 passes through the lower formwork 2 and communicates with the atmosphere. Both the slide plate 3 and the upper formwork 301 are dug with a second cooling water channel 502. The waterway ...

Embodiment 2

[0043] refer to Figure 1-8 , an aluminum alloy die-casting mold with rapid cooling and cooling functions, comprising a bottom plate 1, a lower template 2 and an upper template 301, the lower template 2 is connected to the bottom plate 1, and the lower template 2 is connected to a limit rod 4, and the limit rod 4 is far away from the One end of the lower formwork 2 is connected with a slide plate 3, the slide plate 3 is slidably connected to the limit rod 4, the upper formwork 301 is connected to the bottom of the slide plate 3, and the lower formwork 2 is dug with a mold groove 201 matching the upper formwork 301, and the lower formwork 2, a water tank 202, a first cooling water channel 501 and a third cooling water channel 503 are excavated respectively. The end away from the water tank 202 passes through the lower formwork 2 and communicates with the atmosphere. Both the slide plate 3 and the upper formwork 301 are dug with a second cooling water channel 502. The waterway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com