Small tyre repairing vulcanizing machine

A vulcanizing machine and tire technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of reducing repair efficiency, prolonging repair time, and short service life of tires, so as to ensure repair quality, uniform pressure distribution, and prolong service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

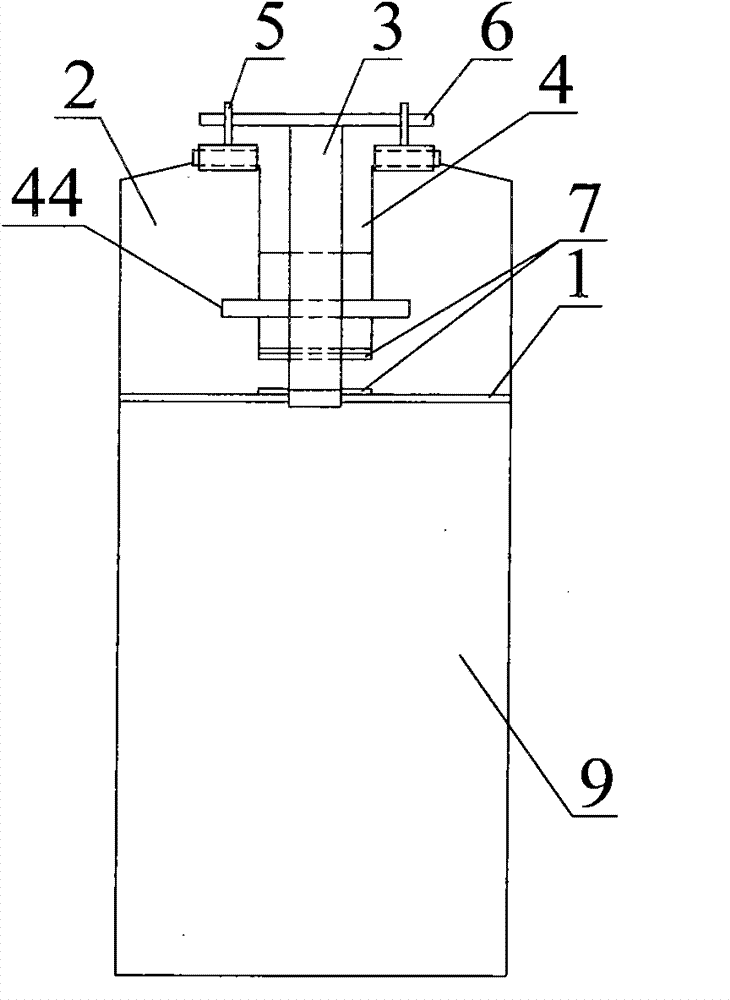

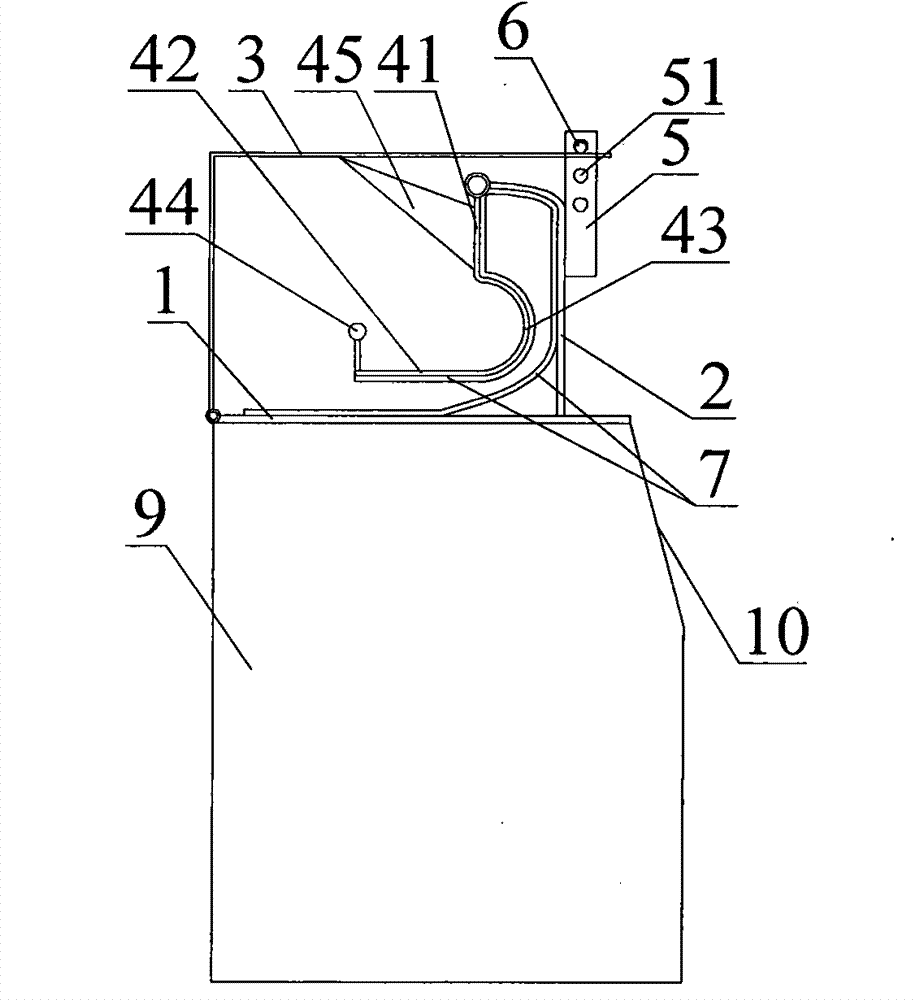

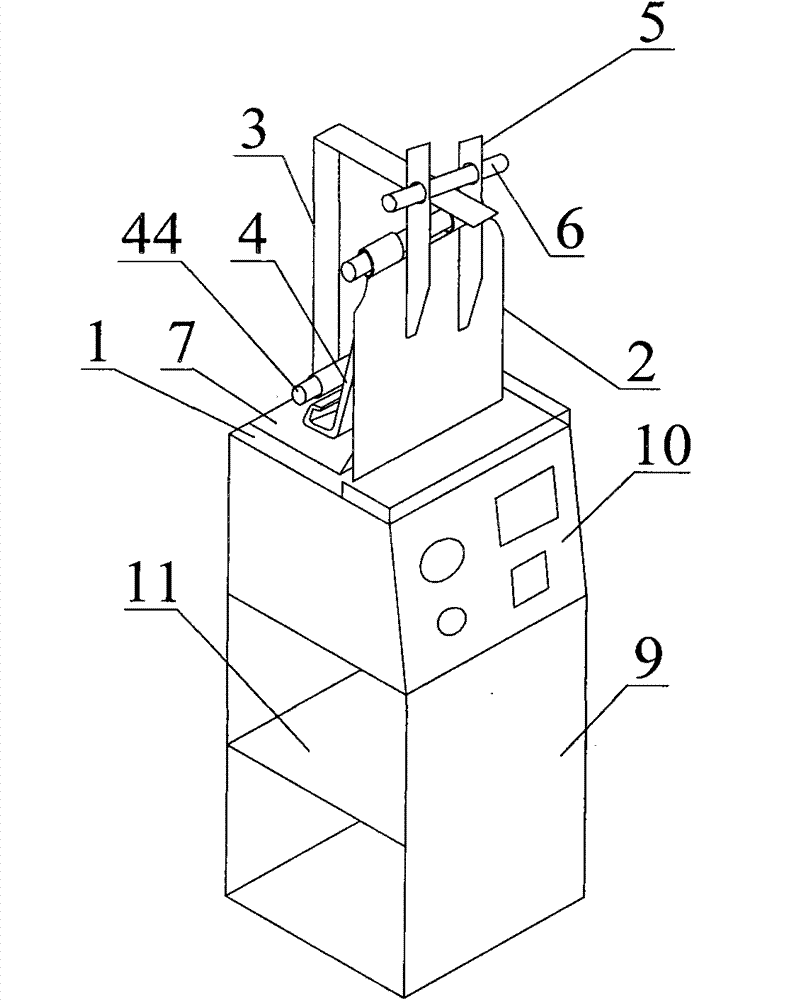

[0030] Such as figure 1 , figure 2 with image 3 The small tire repair vulcanizing machine shown includes a workbench 1, a fixed vertical plate 2, an outer pressure plate 3 and an inner pressure plate 4, the fixed vertical plate 2 is fixed on one side of the workbench 1, and the outer pressure plate 3 is hinged on the workbench On the other side of 1, the upper end of the inner pressure plate 4 is hinged on the fixed vertical plate 2 top, and the top of the outer pressure plate 3 is higher than the top of the inner pressure plate 4. The outer pressure plate 3 is shape, the inner pressure plate 4 is Shape, the outer pressure plate 3 is hinged with the workbench 1 through its lower part, and the inner pressure plate 4 is hinged with the fixed vertical plate 2 through its upper part. The outer pressure plate 3 is fastened by the connecting piece on the fixed vertical plate 2, and the connecting piece includes two vertical plates 5 and a latch 6 fixed on the upper part of t...

Embodiment 2

[0035] like Figure 5 As shown, the difference from Example 1 is that the heating and vulcanizing plate 8 is located on the outside of the pressure airbag 7 and is attached to it, that is, the pressure airbag 7 is sandwiched between the inner pressure plate 4 and the heating and vulcanization plate 8 In this way, the heating vulcanization plate 8 can be directly contacted with the tire to be repaired, and the heat transfer efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com