A kind of production method of rubber piston for prefilled syringe

The technology of a rubber piston and a production method, which is applied to the field of rubber parts for pre-filled syringes, can solve the problems of high pollution probability in production links, low utilization rate of rubber materials, large waste of leftover materials, etc., and achieves high production efficiency and high output rate. , the effect of less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

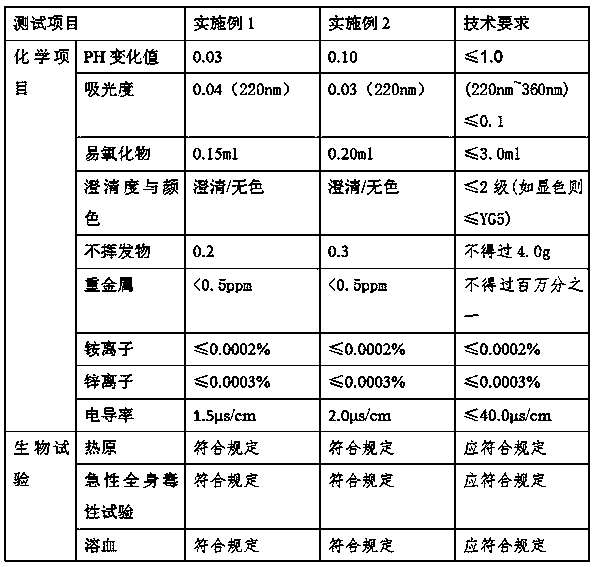

Examples

Embodiment 1

[0024] A 1ml elongated prefilled syringe with a bromobutyl rubber plunger, produced as follows:

[0025] A. Ingredients: Accurately weigh 100 parts by weight of bromobutyl rubber BIIR2211, 5 parts by weight of precipitated silica, 70 parts by weight of calcined kaolin, 1.0 parts by weight of insoluble sulfur, 3.0 parts by weight of zinc oxide, 1.0 parts by weight of stearic acid, 4.0 parts by weight of magnesium oxide, 10 parts by weight of low molecular weight polyethylene wax, 4 parts by weight of titanium dioxide, 0.8 parts by weight of carbon black, for subsequent use;

[0026] B. Internal mixing: Mix the weighed raw materials evenly with a powerful pressurized internal mixer with a capacity of 75 liters, and operate according to the appropriate internal mixing process. The internal mixing cycle is 8-15 minutes, and the actual internal mixing rubber material The temperature is 100-120°C, and the mixed rubber is prepared for use;

[0027] C. Open mixing and stamping: on th...

Embodiment 2

[0035] A 1ml standard prefilled syringe for chlorobutyl rubber plunger, the production steps are as follows:

[0036] A. Ingredients: Accurately weigh 100 parts by weight of chlorinated butyl rubber CIIR1066, 30 parts by weight of talcum powder, 50 parts by weight of calcined kaolin, 2.0 parts by weight of alkyl phenolic vulcanized resin, 5.0 parts by weight of zinc oxide, 1.0 parts by weight of stearic acid, 1.0 parts by weight of magnesium oxide, 5 parts by weight of polyisobutylene, 3 parts by weight of titanium dioxide, 0.6 parts by weight of carbon black, for subsequent use;

[0037] B. Internal mixing: Mix the weighed raw materials evenly with a powerful pressurized internal mixer with a capacity of 75 liters, and operate according to the appropriate internal mixing process. The internal mixing cycle is 8-12 minutes, and the actual internal mixing rubber material The temperature is 100-120°C, and the mixed rubber is prepared for use;

[0038]C. Open mixing and stamping:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com