Machining method for pre-vulcanizing lining layer of all-steel tire by utilizing electron beams

A processing method and pre-vulcanization technology, which is applied in the field of electron beam pre-vulcanization of the inner liner of all-steel tires, can solve the problems of poor rubber performance, uneven vulcanization, waste of materials, etc., and reduce the weight of finished tires and rubber materials. Penetration, the effect of improving the quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

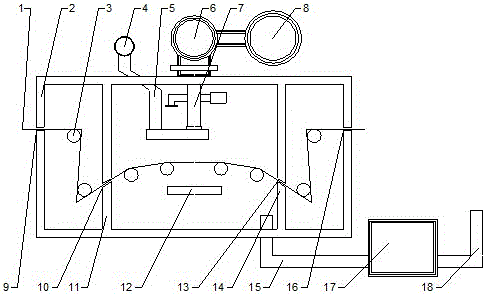

[0033] The invention discloses a processing method of an electron beam prevulcanized all-steel tire inner liner. The specific flow of the processing method is as follows:

[0034] (1) Start the production line: start the inner lining production line, so that the inner lining film starts to move to the pre-vulcanization equipment;

[0035] (2) Start the equipment: when the inner lining film enters the pre-vulcanization equipment, start the equipment;

[0036] (3) Electron beam emission: After the equipment is started, the voltage begins to rise. When the voltage reaches 500KV and is stable, the equipment emits electron beams to irradiate the inner lining film. At this time, it is necessary to manually mark the parts with a crayon. , the parts before this mark are the parts to be returned to the furnace, which need to be cut and returned to the furnace again, and the parts to be returned to the furnace must be distinguished from the unirradiated parts and returned to the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com