Tire segment mold

A tire flexible mold and mold technology, which is applied to tires, household appliances, and other household appliances, can solve problems such as cost increase, heating heat waste, and service life impact, so as to avoid heat waste, control parameters accurately, and improve tire performance. Effect of Vulcanization Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

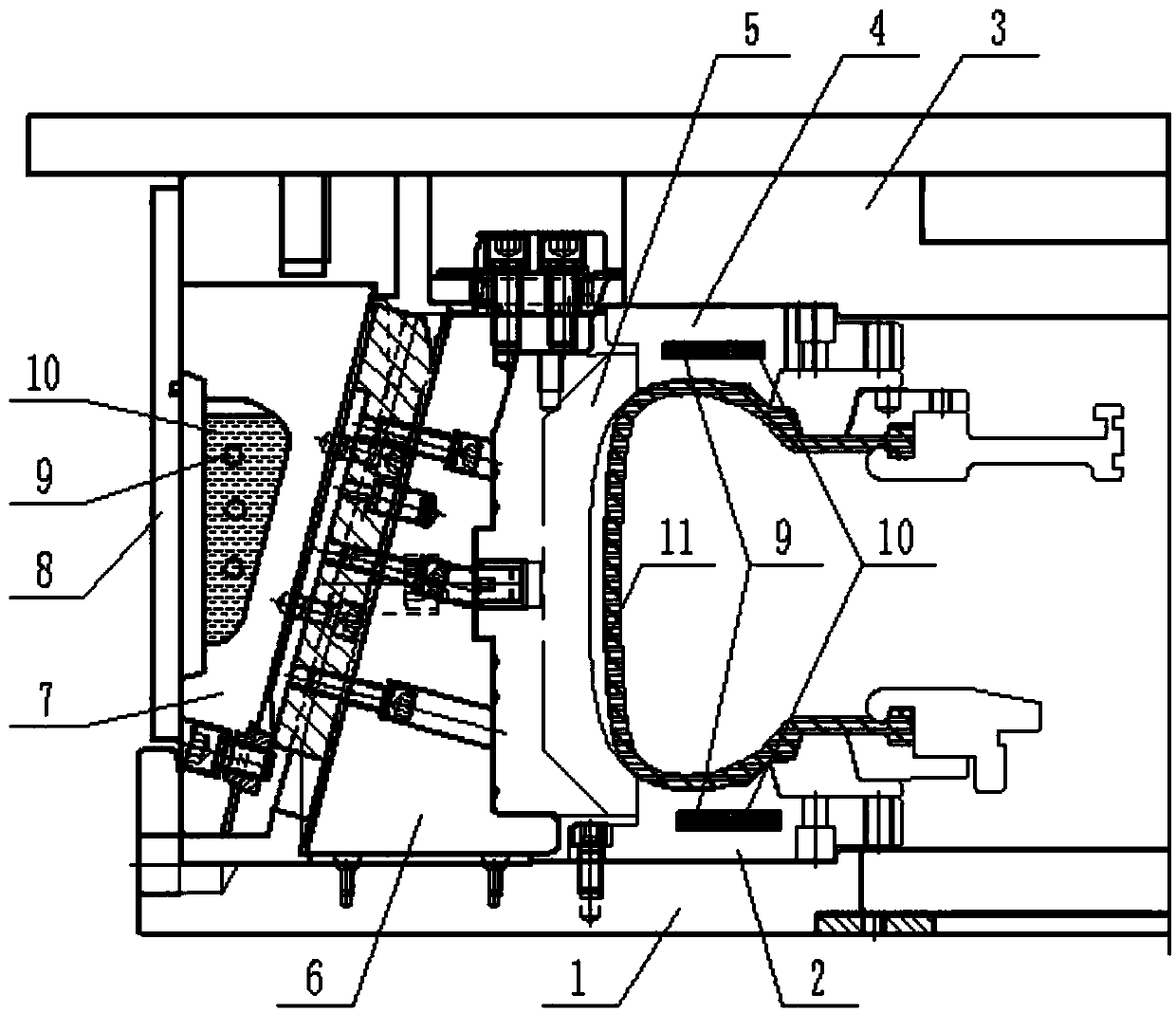

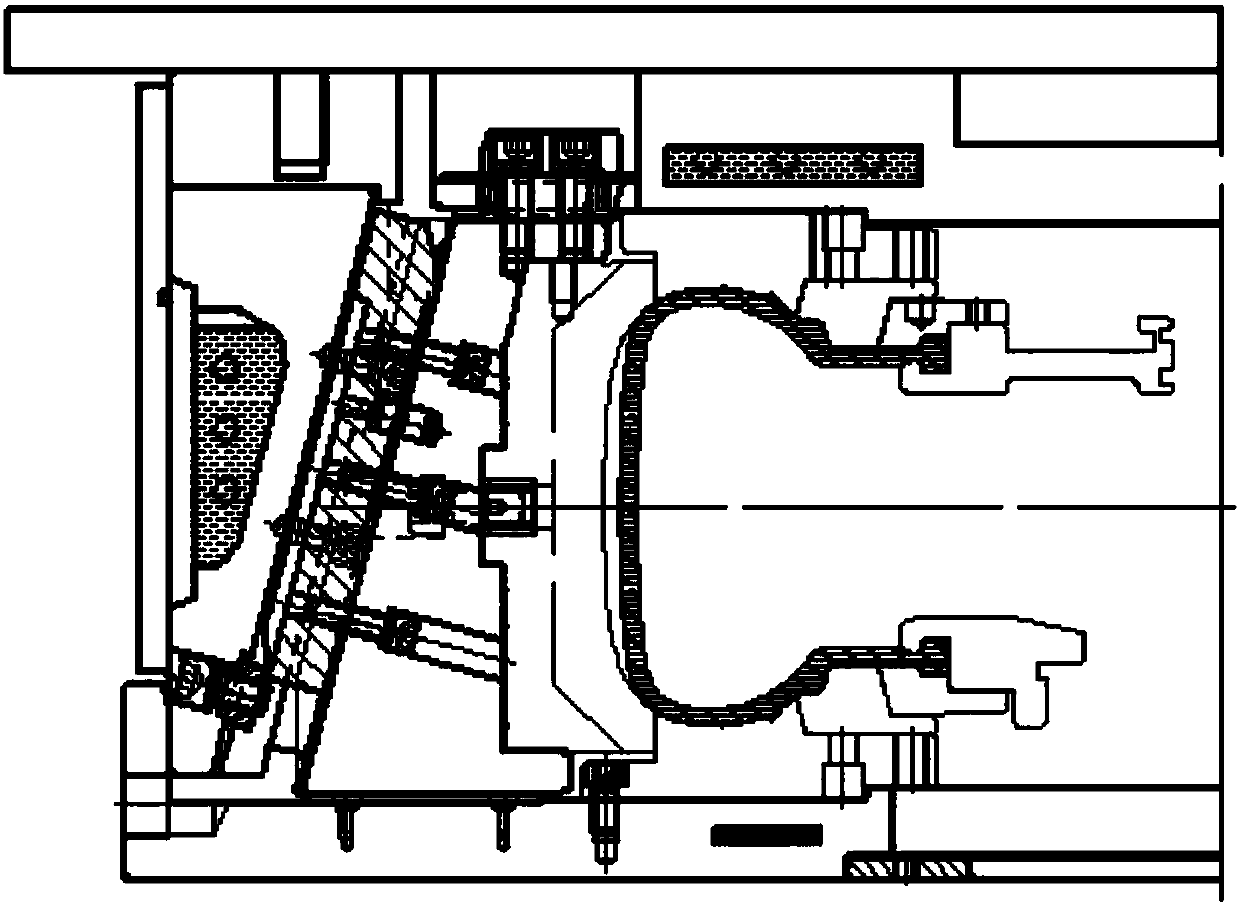

Embodiment 1

[0027] The airtight heating chamber is arranged in the middle mold cover 7, or in the tread block 5, or in the slide block 6. At the same time, the upper side plate 4 and the lower side plate 2 are also provided with an airtight heating chamber. The above airtight heating chamber All are equipped with electric heating device 9 and water.

Embodiment 2

[0029] The airtight heating chamber is arranged in the middle mold cover 7, or in the pattern block 5, or in the slide block 6. At the same time, the upper cover 3 and the base 1 are also provided with an airtight heating chamber. Electric heating device 9 and water.

[0030] In order to further avoid the waste of heat, the outer side of the middle mold cover 7 is provided with an insulating layer 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com