Removable gas hole type flat panel vulcanizing machine

A flat vulcanizer and vulcanizer technology, which is applied in the field of polymer processing equipment, can solve problems affecting the mechanical properties of rubber materials, and achieve the effects of uniform thickness of vulcanized materials, improved vulcanization quality, and complete vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

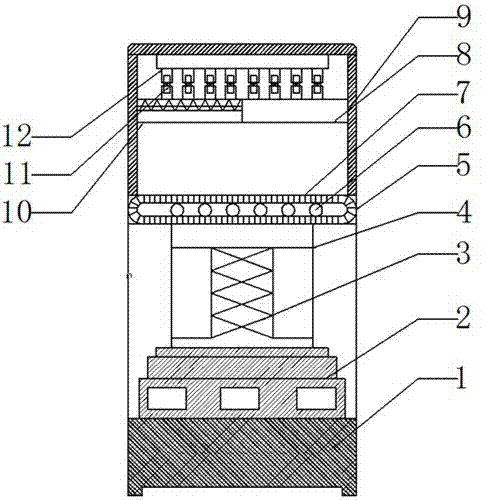

[0018] A flat vulcanizing machine with detachable pores, characterized in that it includes a base of the vulcanizing machine, a hydraulic cylinder base directly above the base, a hydraulic device installed above the base of the hydraulic cylinder, the top of the hydraulic device is connected to the center of the hydraulic top plate, and the inside of the hydraulic top plate There is a crawler-type rotating plane with crawler belts, on the surface of the crawler-type rotating plane, there is a lower plate of the vulcanizing machine, and a hot-pressed vulcanizing plate is installed directly above the crawler-type rotating plane. The bottom of the plate is the upper plate of the vulcanizer, the bottom of the cyclic vibration device is fixedly connected with the hot-press vulcanization plate, and the bottom of the cyclic vibration device is fixedly connected with the top seat of the vulcanizer. A vulcanization method for a pore-removable flat plate vulcanizer, which is characterize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com