Locking ring pole type hydraulic tyre vulcanizing machine pressurize from inside

A tire vulcanization and hydraulic technology, which is applied to the field of internal pressure lock-ring column hydraulic tire vulcanizers, can solve problems such as the influence of mold life, increase manufacturing costs, and difficult maintenance, so as to reduce manufacturing costs and maintenance costs, and improve tires. Vulcanization quality, improve the effect of mold regulation and pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

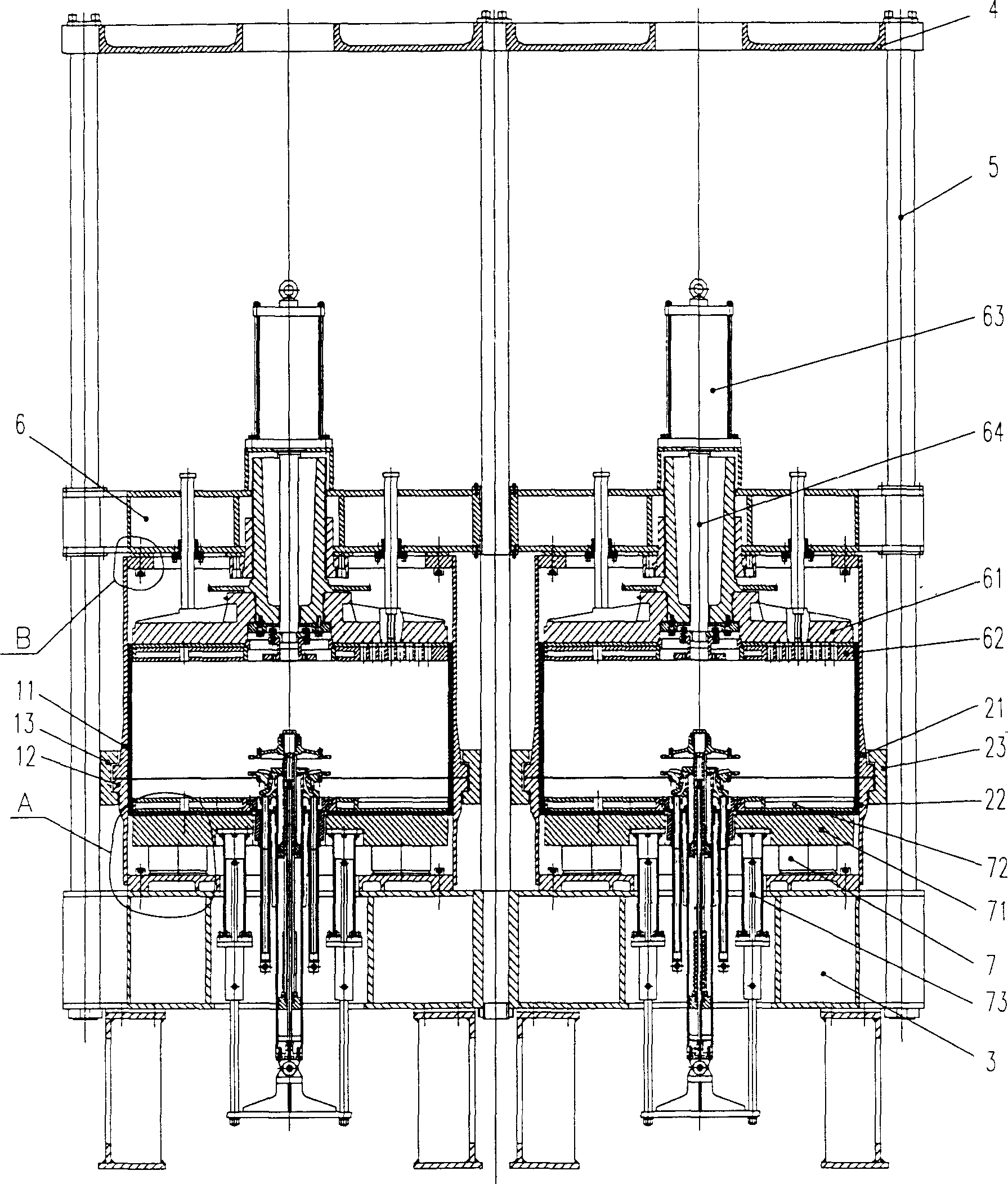

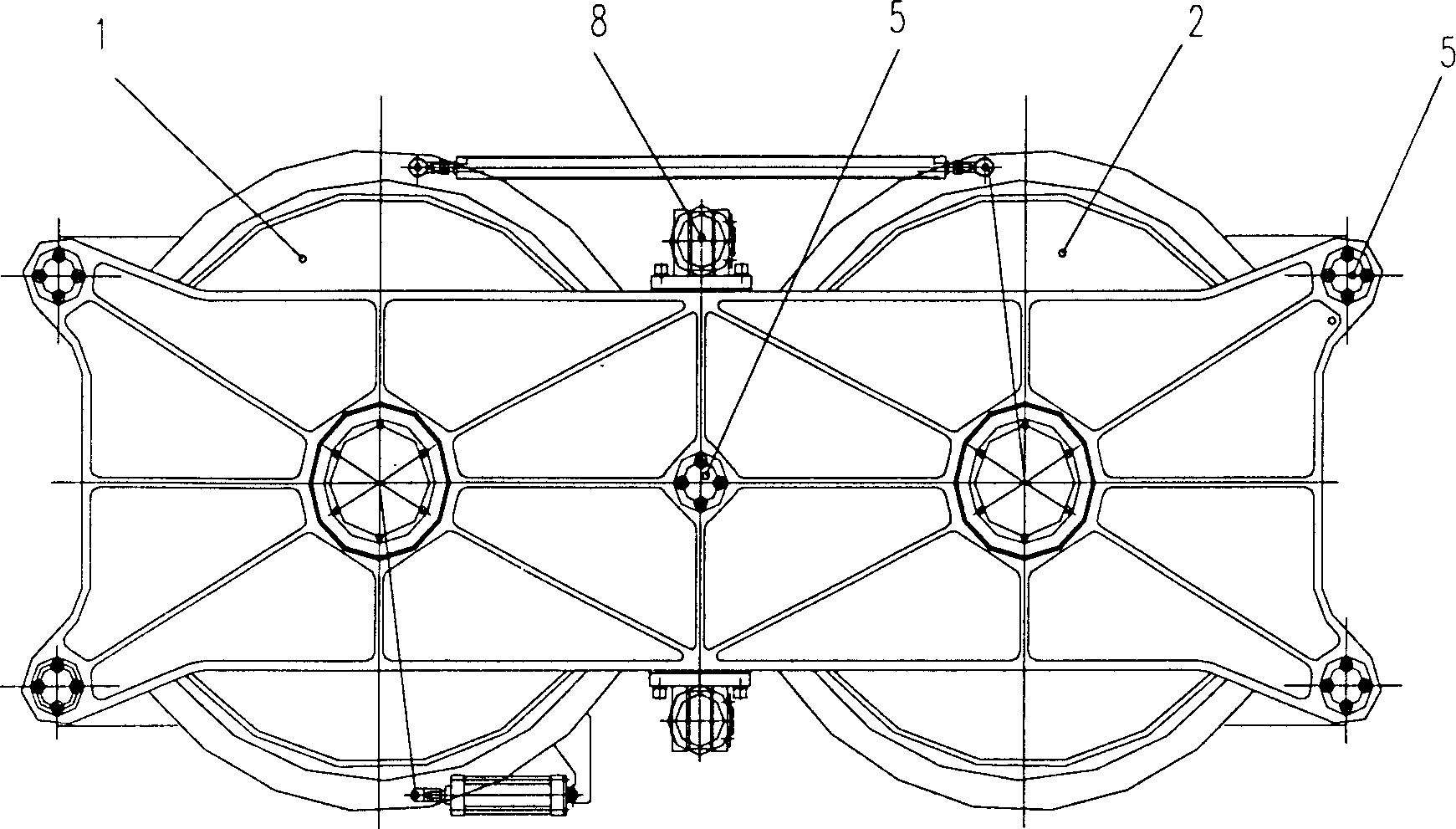

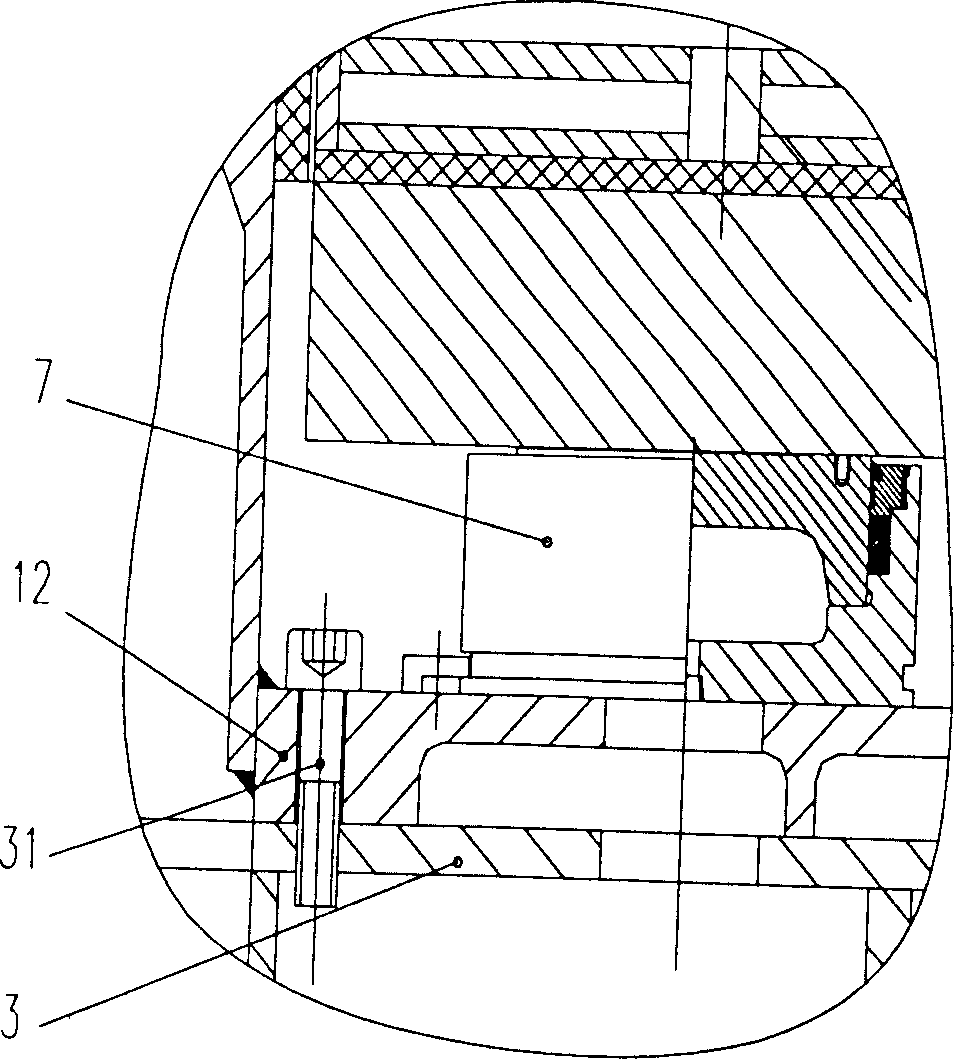

[0033] Embodiment one, see Figure 1 to Figure 5As shown, a hydraulic tire vulcanizer of the present invention is a hydraulic tire vulcanizer with a five-column dual-mode structure, which includes two cylinders, namely the left cylinder 1 and the right cylinder 2, and a base 3. The upper support plate 4 and five columns 5, the upper end of each column 5 is fixedly connected with the upper support plate 4, and the lower end is fixedly connected with the base 3 respectively, and the five columns 5 are distributed at the four corners and the middle position ; Left cylinder 1 is provided with left upper cylinder 11, left lower cylinder 12, right cylinder 2 is provided with right upper cylinder 21, right lower cylinder 22, and left lower cylinder 12, right lower cylinder 22 its respective bottom plate adopts respectively The screw 31 is fixedly connected with the base 3, and six mold clamping pressurization cylinders 7 are respectively fixed on the bottom plates of the left lower c...

Embodiment 2

[0036] Embodiment two, see Figure 6 As shown, the present invention is a five-column double-mode vulcanizing machine with internally pressurized locking ring column type hydraulic tire vulcanizing machine. Instead, it is mounted on both sides, that is, the left and right positions.

Embodiment 3

[0037] Embodiment three, see Figure 7 As shown, a kind of internal pressurized locking ring column type hydraulic tire vulcanizing machine of the present invention is a four-column double-mode vulcanizing machine. The front and back of the side are respectively socketed with a column 5 slidingly, and four columns 5 are on the four corner positions of the elevating beam 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com