Electromagnetic-heating tire vulcanizing device capable of controlling heat source temperature segment by segment

A heat source temperature, tire technology, applied in the field of tire production technology and equipment, to achieve the effects of high heat transfer efficiency, prevention of oversulfurization, and improvement of vulcanization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

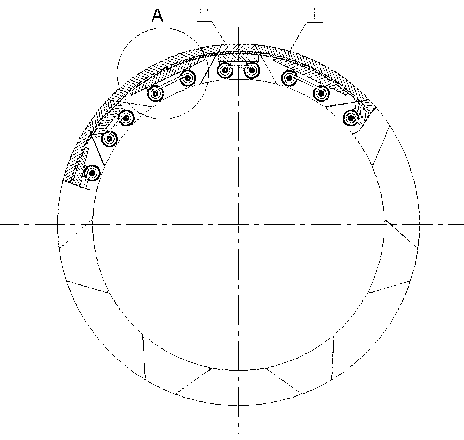

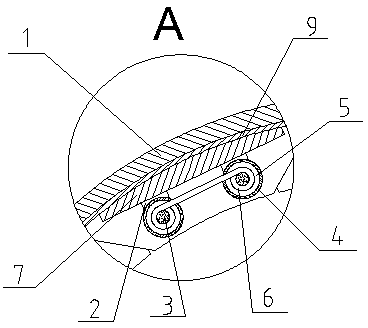

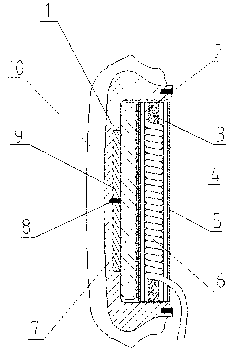

[0015] The present invention will be further described in conjunction with the accompanying drawings and embodiments. see Figure 1 ~ Figure 4 , is to replace the vulcanization bladder on the central mechanism of the tire shaping vulcanizer with a radially expandable metal inner mold. The inner mold mainly consists of n pieces of wide drum tiles 1 and n pieces of narrow drum tiles 11 (n is an integer not less than 5 ), the ribs 7 are fixedly connected with the drum tiles and play a supporting role. The wide drum tiles 1 and the narrow drum tiles 11 are arranged alternately along the circumferential direction. The inner contour curves are consistent. During vulcanization, the inner mold is in an expanded state, and the wide drum tile 1 and the narrow drum tile 11 are closely attached to form a complete circle in appearance. The outer diameter of the circle is equal to the inner diameter of the finished tire. A mold cavity with a certain depth is opened in the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com