Hydraulic tyre vulcanizing machine in column type strap clamp locked mould mode, and method for adjusting mould

A tire vulcanization and vulcanizing machine technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of poor positioning and guidance, reduced weight of the whole machine, and large maintenance of mechanical structure, so as to reduce manufacturing costs and use maintenance. cost, improve tire vulcanization quality, and reduce maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

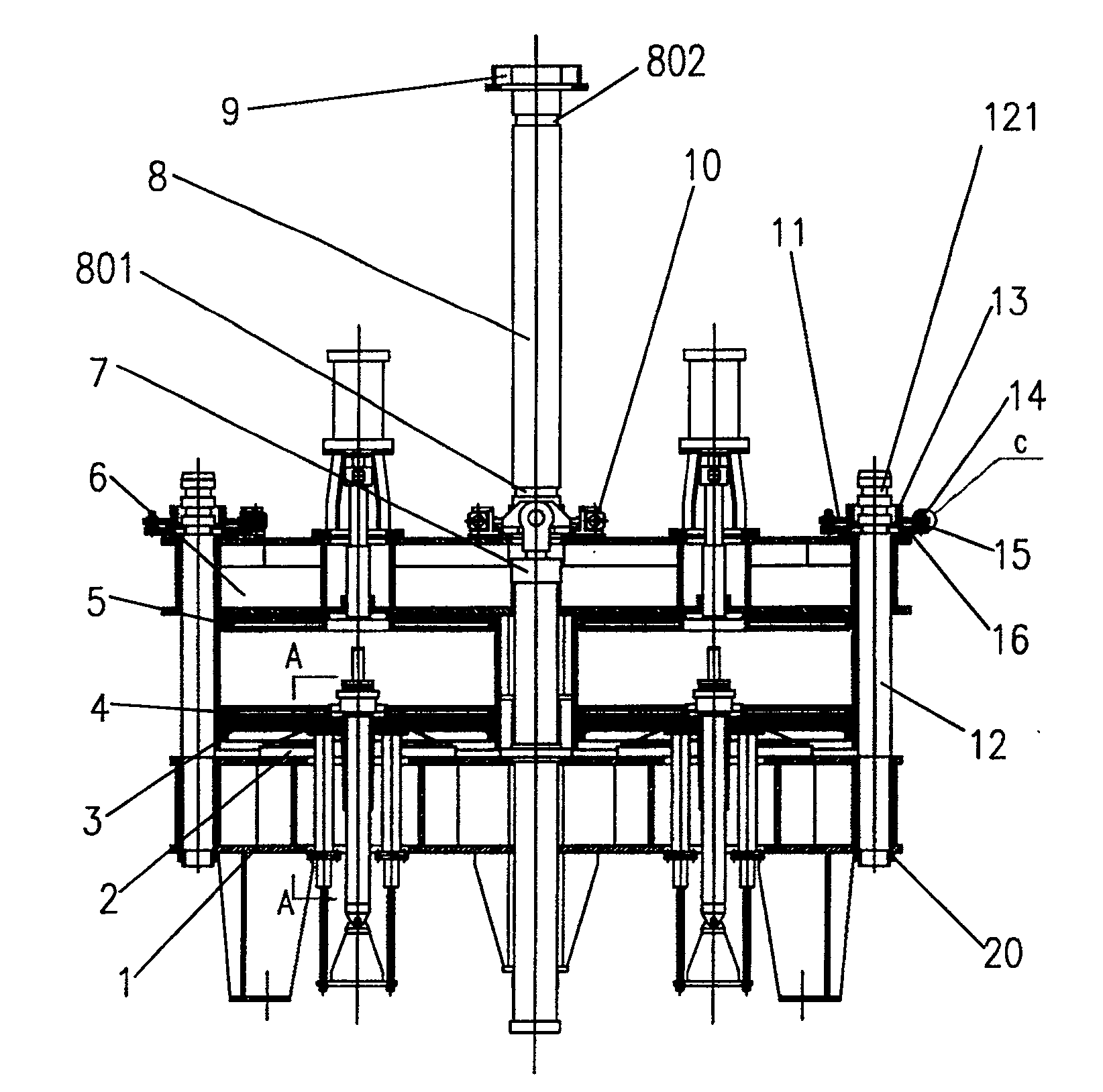

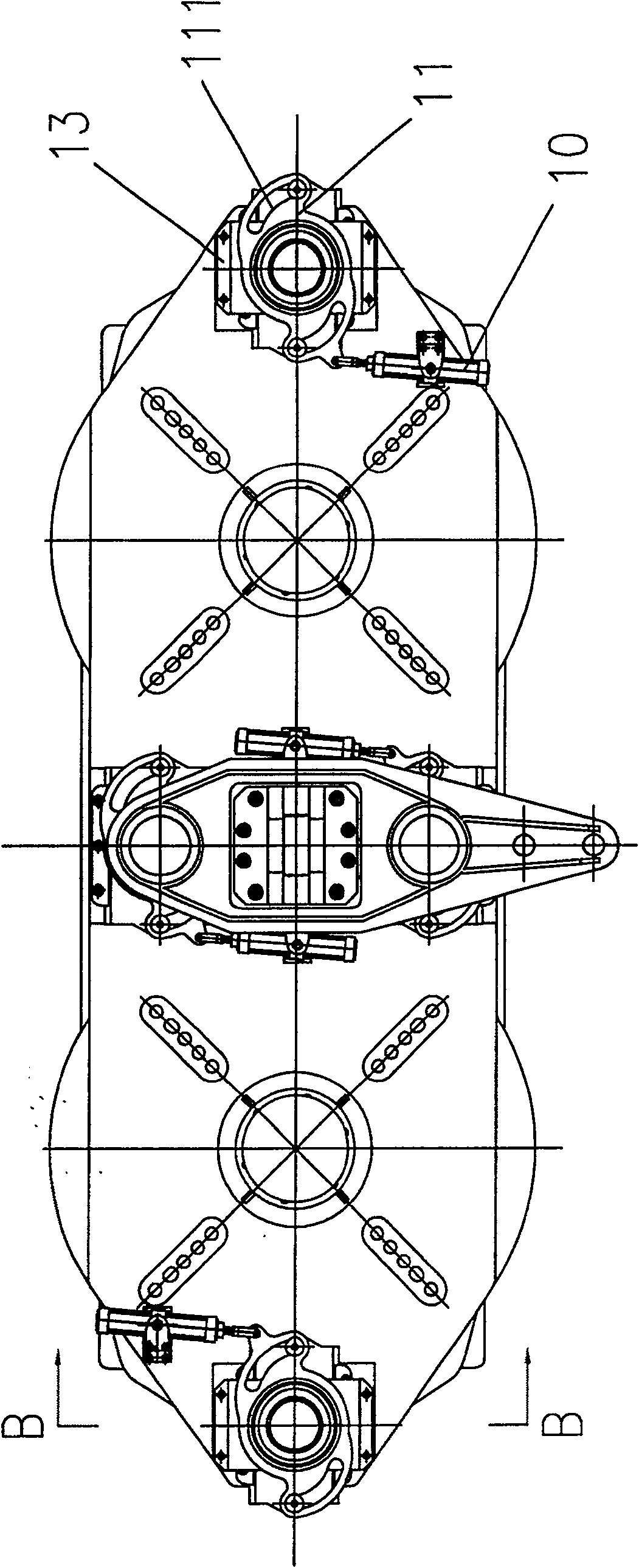

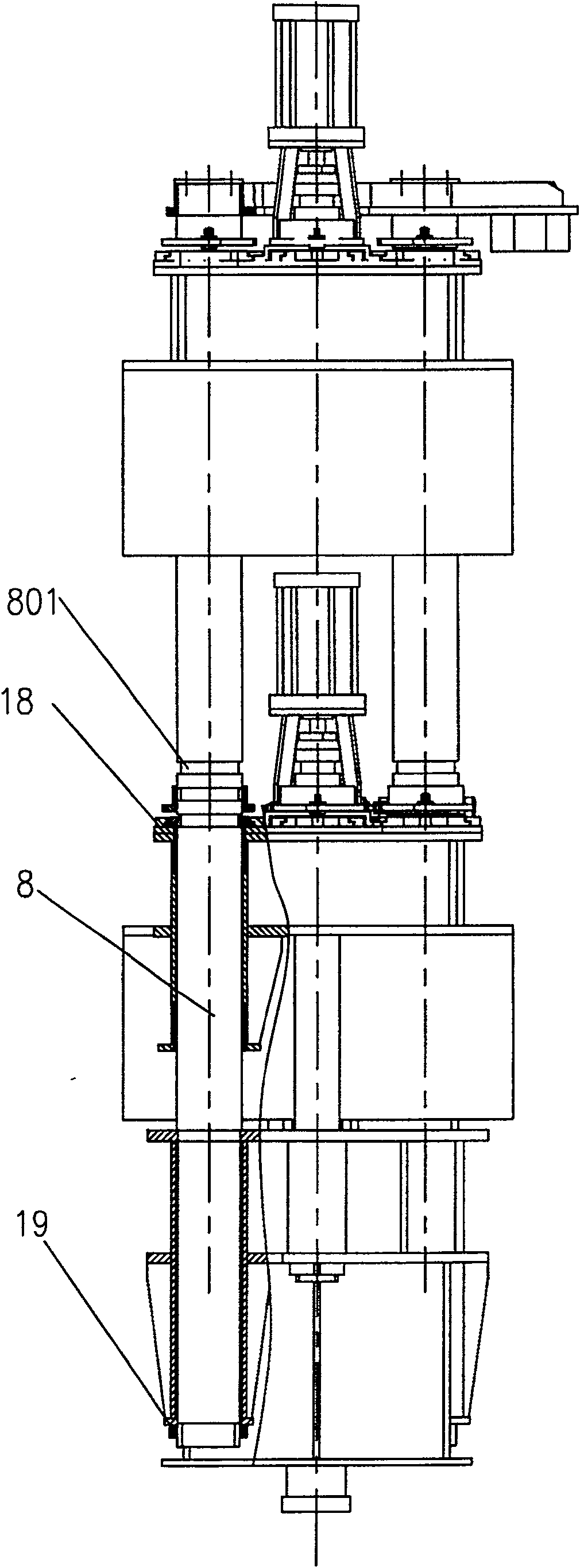

[0037] Embodiment one, see Figure 1 to Figure 6 As shown, a hydraulic tire vulcanizer with a column clamp lock mode of the present invention is a hydraulic tire vulcanizer with a double-column double-mode structure, which includes a base 1, a plurality of pressurized oil cylinders 2, and a lower supporting plate 3, which can be used for mounting The upper hot plate 5 and the lower hot plate 4 connected to the upper and lower molds of the tire mold, the upper beam that can be lifted and lowered 6, the mold opening and closing cylinder 7, the column 8 used to guide the mold opening and closing and bear the clamping force, the upper bracket 9, Auxiliary column 12 and pallet type mold clamping device; pallet type mold clamping device includes clamping cylinder 10, clamping cam 11, cam bracket 13, clamping bearing 14, small shaft 15, clamping platen 17 and can be connected with column or auxiliary column The clamping plate 16 engaged with the annular groove.

[0038] Among them, ...

Embodiment 2

[0049] Embodiment two, see Figure 7 , Figure 8 As shown, a hydraulic tire vulcanizing machine with column clamp lock mode of the present invention is a four-column double-mode hydraulic tire vulcanizing machine, which is different from Embodiment 1 in that it consists of two opening and closing molds arranged The oil cylinder 7 replaces the one in the first embodiment, and the two uprights and the two auxiliary uprights in the first embodiment are replaced by four uprights 8 arranged at the four corners of the machine.

Embodiment 3

[0050] Embodiment three, see Figure 9 As shown, a hydraulic tire vulcanizing machine with column clamp lock mode of the present invention is a six-column double-mode hydraulic tire vulcanizing machine. Die oil cylinder 7 replaces one of embodiment one, and replaces two uprights and two auxiliary uprights of embodiment one by six uprights 8 arranged at the four corners of the machine and the front and rear sides of the middle part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com