Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

A technology for rapid vulcanization and vulcanization of rubber, applied in applications, footwear, apparel, etc., can solve problems such as large temperature difference, uneven temperature of vulcanization tank, inability to coordinate the relationship between vulcanization speed and scorch safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

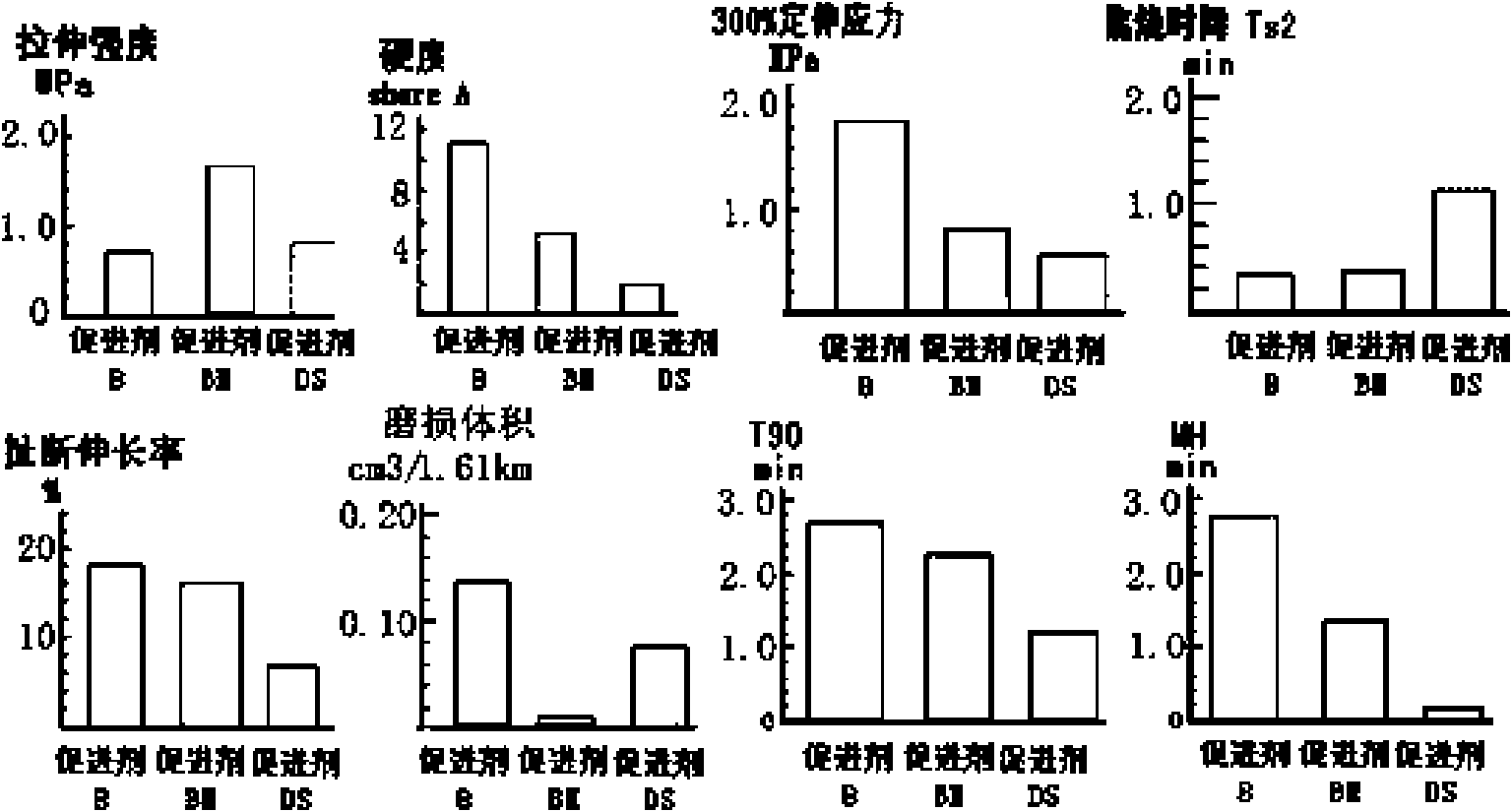

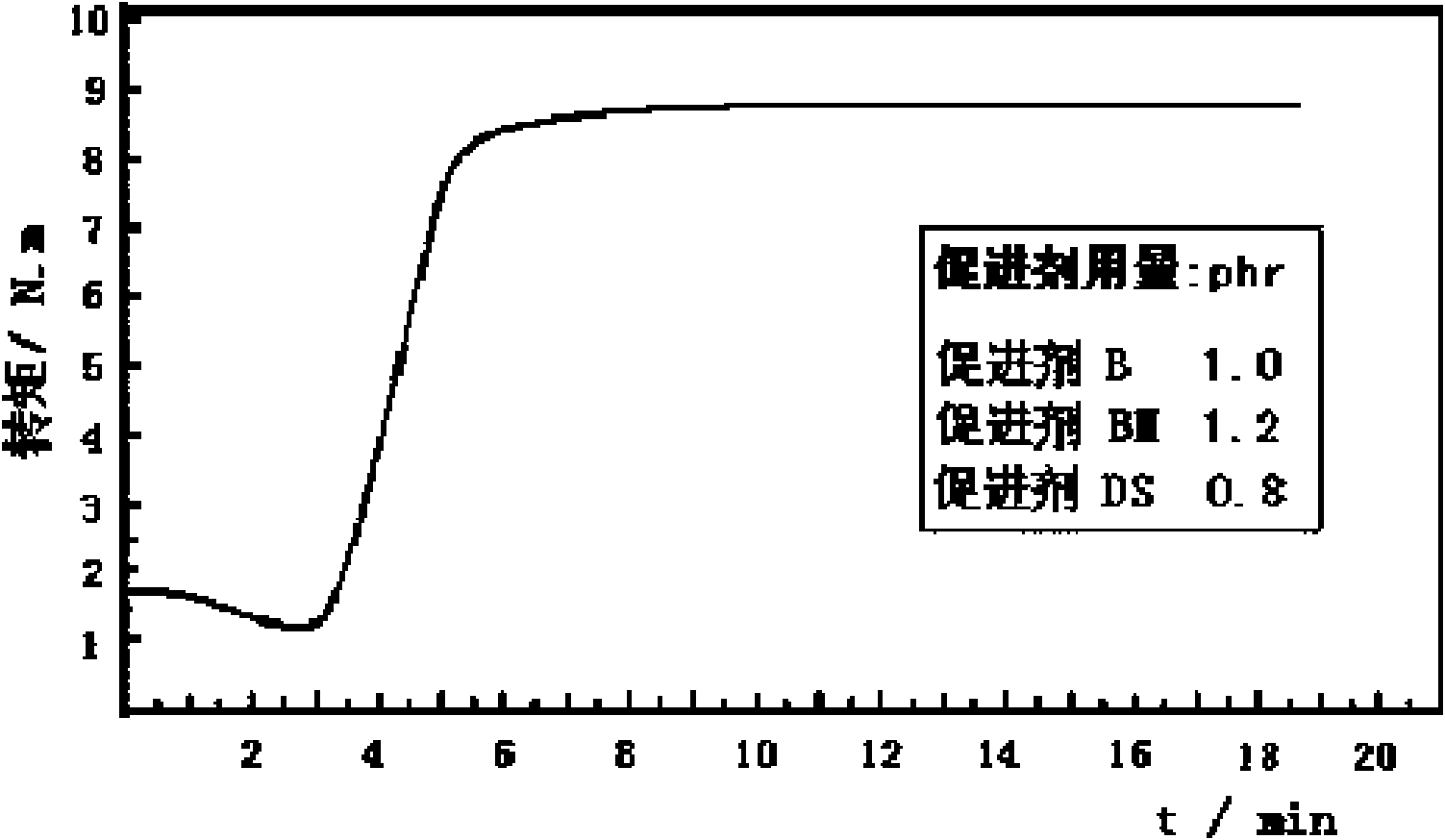

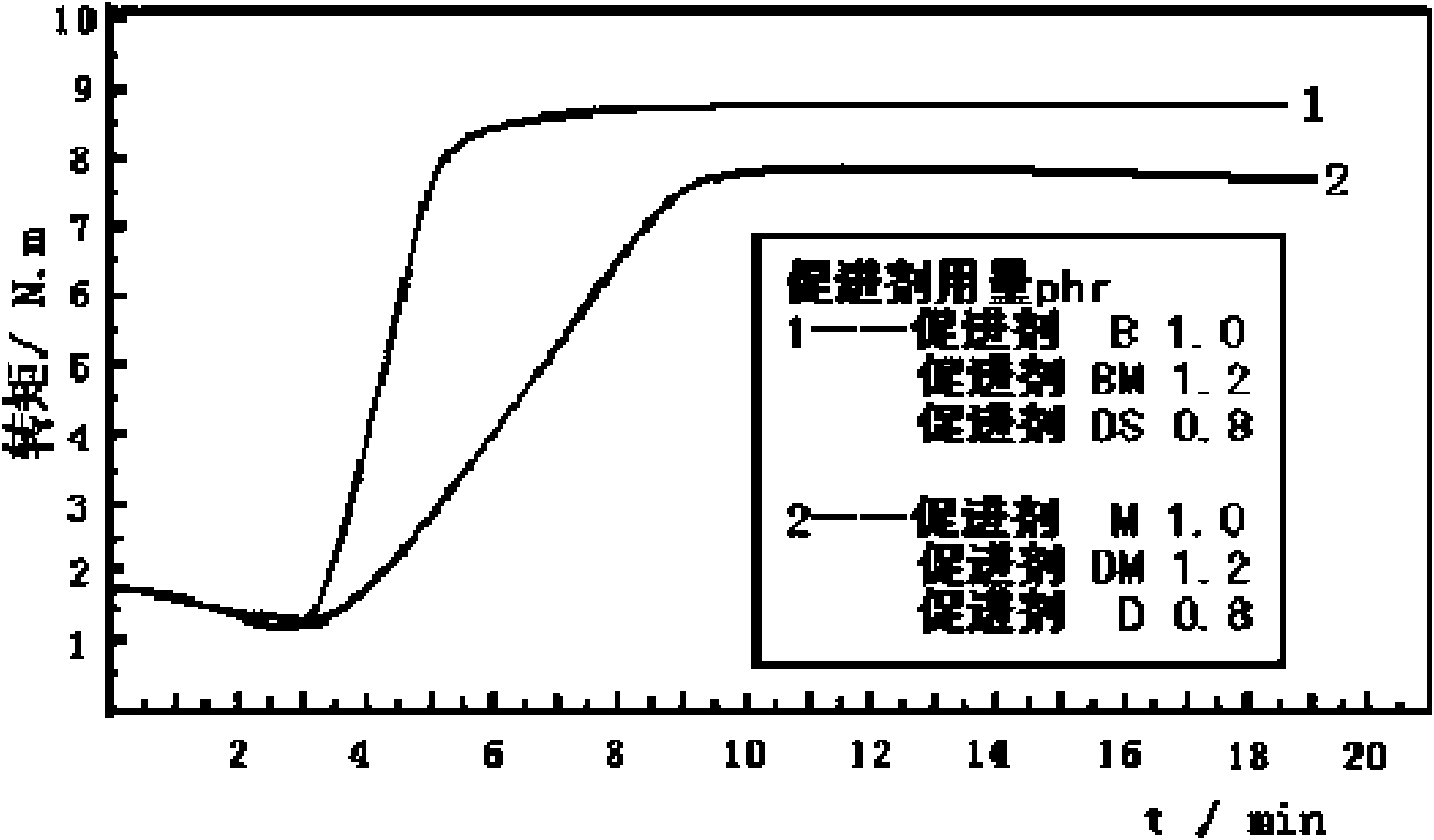

[0178] Embodiment 1: natural rubber (2# standard rubber) 40kg, styrene-butadiene rubber 30kg, butadiene rubber 30kg, accelerator B 1kg, accelerator BM 1.2kg, accelerator DS 0.8kg, nano zinc oxide 2kg, rubber softening oil 20kg , sulfur 2kg, stearic acid 2kg, antioxidant CD 2.3kg, N330 carbon black 80kg, pine tar 8kg, solid coumarone 18kg, reclaimed rubber 17kg, clay 25kg.

[0179] Preparation:

[0180] 1. Preparation of unvulcanized rubber semi-finished products

[0181] (1) Preparation of plasticized rubber: take 2# standard rubber and reclaimed rubber and banbury on a rubber mixer for 5 minutes to make its Vickers plasticity reach 0.30-0.40, and roll it on an open rubber mixer to obtain plasticized rubber. Store overnight;

[0182] (2) Preparation of masterbatch: get styrene-butadiene rubber and butadiene rubber and add to internal mixer, add solid coumarone and 1.2kg (60wt%) stearic acid, 32kg (40wt%) carbon black successively, banburying 6min, Add 14kg (70wt%) rubber so...

Embodiment 2

[0195] Embodiment 2: natural rubber (2# standard rubber) 35kg, styrene-butadiene rubber 35kg, butadiene rubber 25kg, accelerator B1.2kg, accelerator BM 1.4kg, accelerator DS 0.6kg, nano zinc oxide 2.2kg, rubber softening 18kg of oil, 1.8kg of sulfur, 2.2kg of stearic acid, 2.5kg of antioxidant CD, 75kg of carbon black, 6kg of pine tar, 20kg of solid coumarone, 20kg of reclaimed rubber and 20kg of clay.

[0196] Preparation:

[0197] 1. Preparation of unvulcanized rubber semi-finished products

[0198] (1) Preparation of mixed rubber: take 2# standard rubber and reclaimed rubber and banbury on a rubber mixer to obtain a plasticized rubber reel, store it overnight for later use; additionally take styrene-butadiene rubber and butadiene rubber, solid coumarone, 1.08kg (60wt%) stearic acid, 30kg (40wt%) carbon black, 13.5kg (75wt%) rubber softening oil, make masterbatch on internal mixer, store overnight standby; Get plasticate and masterbatch again, Put it into the internal mixe...

Embodiment 3

[0205] Embodiment 3: natural rubber (2# standard rubber) 45kg, styrene-butadiene rubber 25kg, butadiene rubber 35kg, accelerator B0.8kg, accelerator BM 1kg, accelerator DS 1kg, nano zinc oxide 1.8kg, rubber softening oil 22kg , sulfur 2.2kg, stearic acid 1.8kg, antioxidant CD 2kg, carbon black 85kg, pine tar 10kg, solid coumarone 16kg, reclaimed rubber 15kg and clay 30kg.

[0206] Prepare and vulcanize according to the method of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com