Vulcanization equipment and method for rubber products

A technology for rubber products and equipment, applied in the field of vulcanization equipment and vulcanization of rubber products, can solve the problems of high labor intensity of workers, low equipment utilization rate, and low degree of automation, and achieves improved vulcanization efficiency, high power utilization rate, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

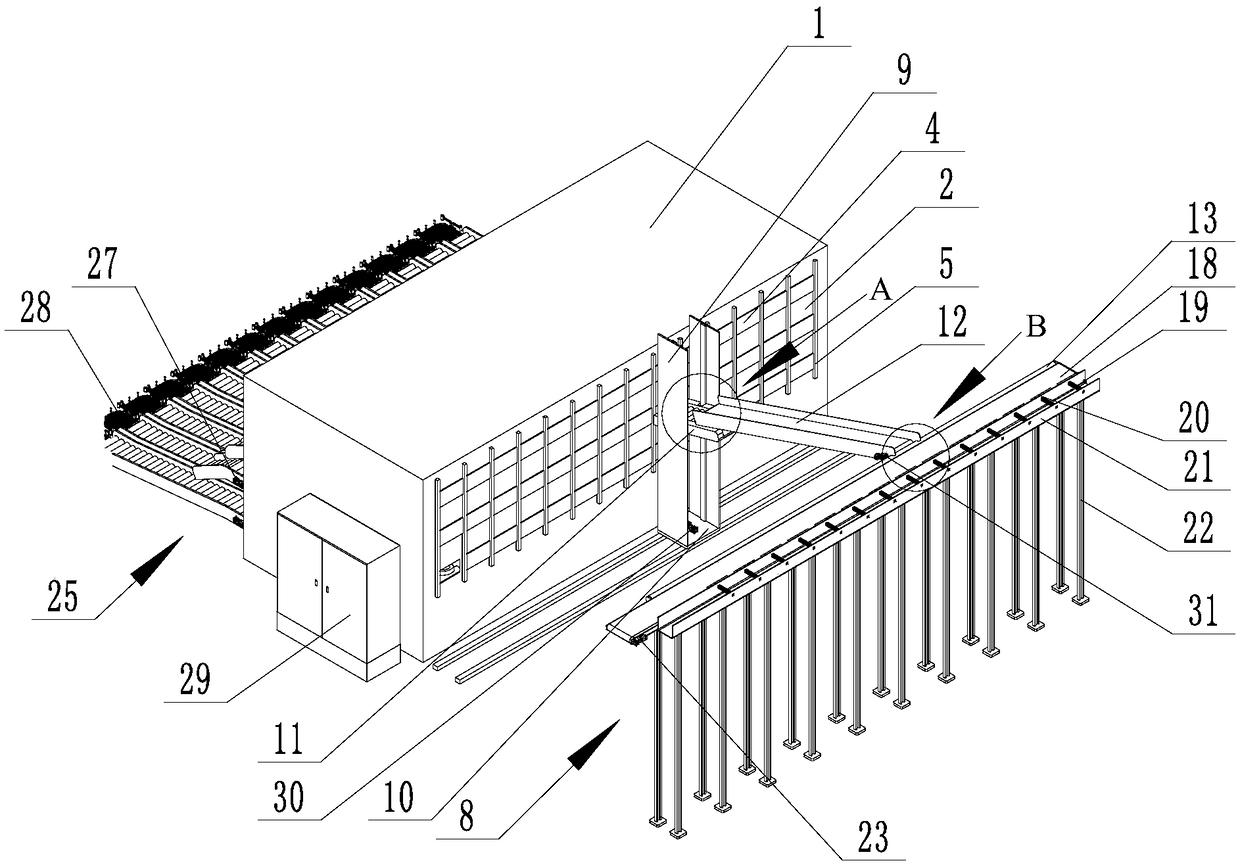

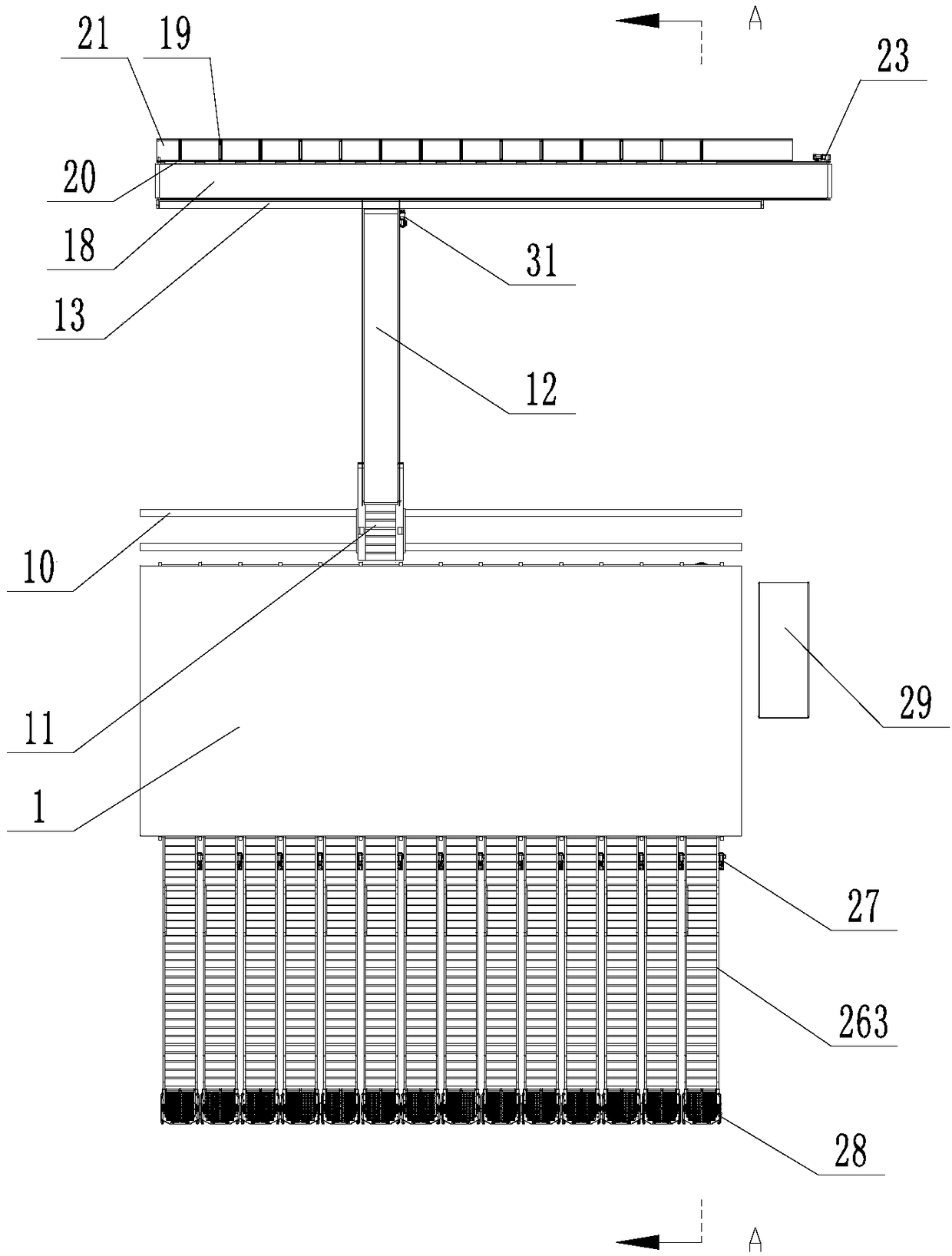

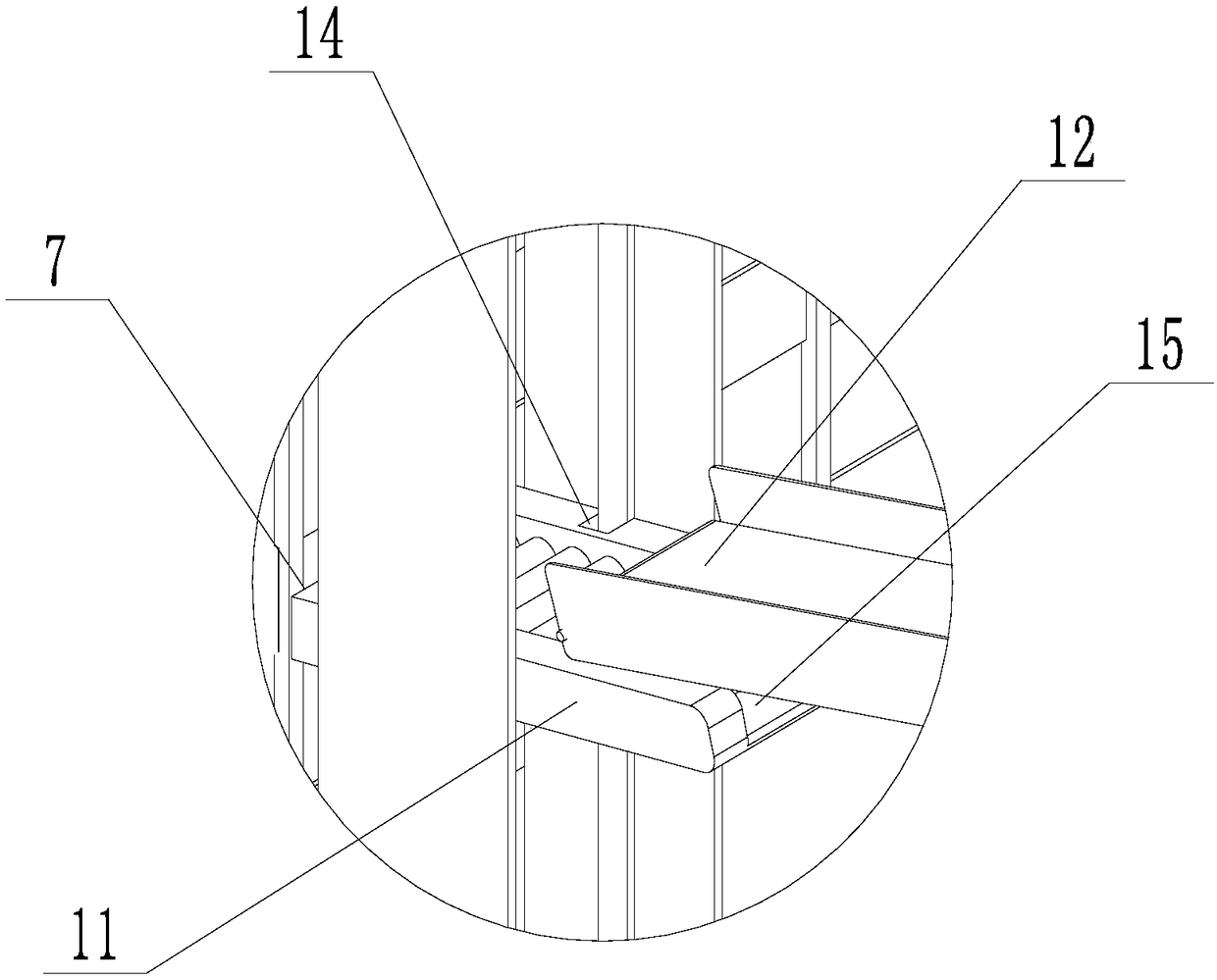

[0054] This embodiment provides a kind of vulcanization equipment for rubber products, such as figure 1 and figure 2 As shown, it includes a constant temperature vulcanization chamber 1, one side of the constant temperature vulcanization chamber 1 is provided with a plurality of vulcanization inlets 2, and the opposite side is provided with a plurality of vulcanization outlets, and the constant temperature vulcanization chamber 1 is provided with a plurality of The vulcanization channel 3 for placing and conveying rubber products arranged obliquely, specifically as Figure 5 As shown, one end of the vulcanization channel 3 communicates with the vulcanization inlet 2, and the other end communicates with the vulcanization outlet, and the angle formed between the vulcanization channel 3 and the horizontal plane toward the vulcanization inlet 2 is an acute angle. . Wherein the arrangement rules and quantity of the plurality of vulcanization passages 3 can be arranged by those s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com