A kind of blending fluorosilicone rubber composition and preparation method

A technology of fluorosilicone rubber and composition, which is applied in the field of fluorosilicone rubber, can solve the problems of lower production efficiency, different cost, different oil resistance requirements, etc., and achieve the advantages of convenient processing, good vulcanization effect, and long blending stability time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

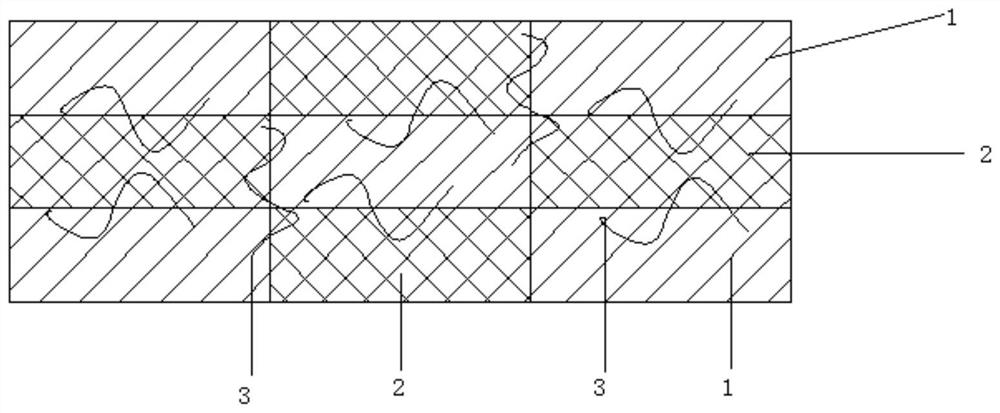

Image

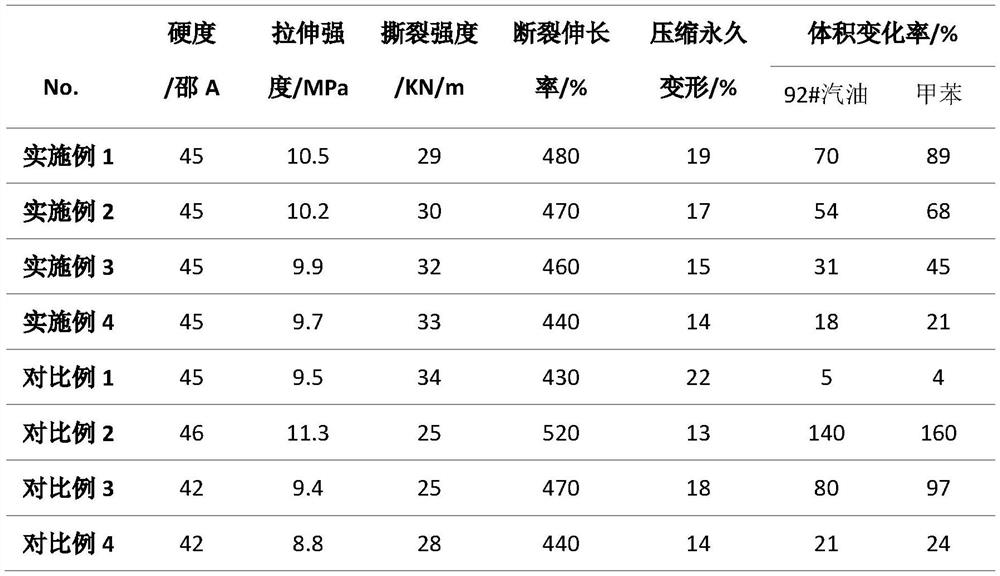

Examples

Embodiment 1

[0040] Put 100 parts of fluorosilicone rubber, 100 parts of silicone rubber and 10 parts of polytrifluoropropylsiloxane-b-polydimethylsiloxane block copolymer with a viscosity of 3000mPa.s on the three-roll machine, and pass it three times , at 170°C, 250Kgf / cm 2 Vulcanized under pressure for 10 minutes, and then secondary vulcanized in an oven at 200°C for 4 hours to obtain blended fluorosilicone rubber 1.

Embodiment 2

[0042] Put 100 parts of fluorosilicone rubber, 70 parts of silicone rubber and 7 parts of polytrifluoropropylsiloxane-b-polydimethylsiloxane block copolymer with a viscosity of 4560mPa.s on the three-roll machine, and pass it three times , at 170°C, 250Kgf / cm 2Vulcanized under pressure for 10 minutes, and then secondary vulcanized in an oven at 200°C for 4 hours to obtain blended fluorosilicone rubber 2.

Embodiment 3

[0044] Put 100 parts of fluorosilicone rubber, 50 parts of silicone rubber and 6 parts of polytrifluoropropylsiloxane-b-polydimethylsiloxane block copolymer with a viscosity of 6220mPa.s on the three-roll machine, and pass it three times , at 170°C, 250Kgf / cm 2 Vulcanized under pressure for 10 minutes, and then secondary vulcanized in an oven at 200°C for 4 hours to obtain blended fluorosilicone rubber 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com