Gold nanoparticle monofilm preparation method and device thereof

A technology of gold nanoparticles and nanoparticles, which is applied in the field of preparation of gold nanoparticle single-layer films, can solve the problems of difficult assembly structure, complicated operation, and harsh assembly conditions, and achieve the advantages of simple preparation method and cleanliness, which are conducive to popularization and application. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

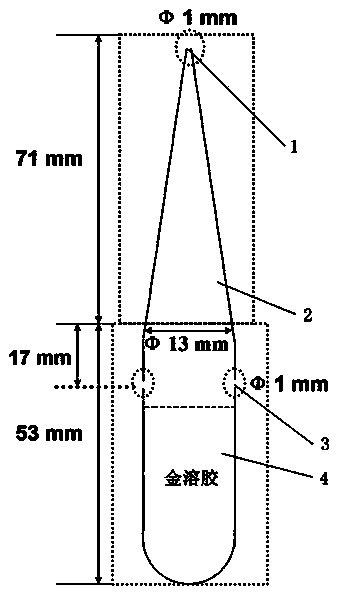

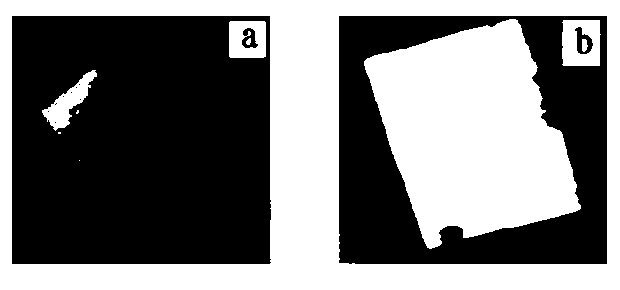

[0033] The present embodiment provides a method for preparing a gold nanoparticle monolayer film, and the specific steps are as follows:

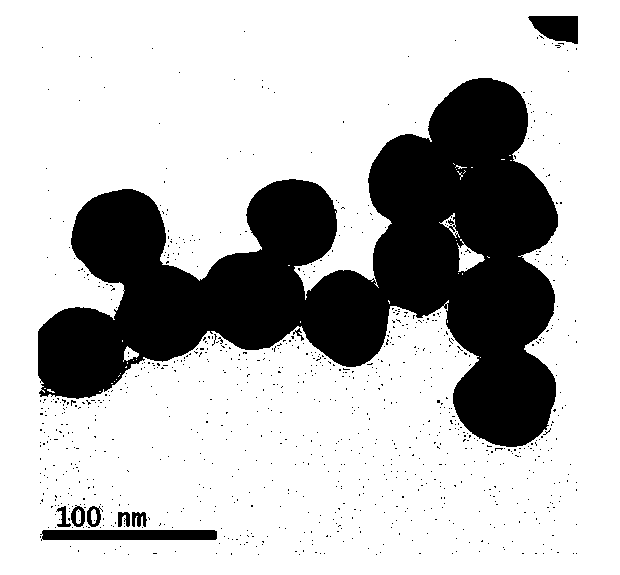

[0034] (1) Add 100 mL of chloroauric acid solution with a concentration of 0.25 mM to a 100 mL three-necked flask, and the solution is light yellow; heat the solution to boiling, and add 2 mL of citric acid with a concentration of 0.01 g / mL under vigorous stirring. Sodium solution. At this time, the solution gradually changed from light yellow to wine red, and the entire color change process took 1 to 3 min. Start timing when the solution turns wine red, keep the system boiling for 15 min under stirring conditions, and then naturally cool to room temperature to obtain 15 nm gold sol.

[0035] (2) Absorb 25 mL of the 15 nm gold sol prepared in step (1), add 1 mL of sodium citrate solution with a concentration of 0.01 g / mL, 1 mL of PVP solution with a concentration of 0.01 g / mL and 20 mL of 2.5 mM hydroxylamine hydrochloride solution. ; 20 ...

Embodiment 2

[0044] A method for preparing a gold nanoparticle monolayer film, the steps are as follows:

[0045] (1) Add 100 mL of chloroauric acid solution with a concentration of 0.25 mM into a 100 mL three-necked flask, the solution is light yellow; heat the solution to boiling, and add 2 mL of citric acid with a concentration of 0.01 g / mL under vigorous stirring sodium solution. At this time, the solution gradually changed from light yellow to wine red, and the entire color change process took 1 to 3 minutes. The timing was started when the solution turned wine red, and the system was kept boiling for 15 min under stirring conditions, and then naturally cooled to room temperature to obtain a 15 nm gold sol.

[0046] (2) Take 25 mL of the 15 nm gold sol prepared in (1), add 1 mL of sodium citrate solution with a concentration of 0.01 g / mL, 1 mL of PVP solution with a concentration of 0.01 g / mL and 20 mL of 2.5 mM hydroxylamine hydrochloride solution; With stirring, 20 mL of 2.5 mM ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com