Irradiation-preheating tire vulcanizing device

A technology of tire vulcanization and irradiation, which is applied to tires, household appliances, and other household appliances, and can solve problems such as energy waste, low tire vulcanization efficiency, and shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

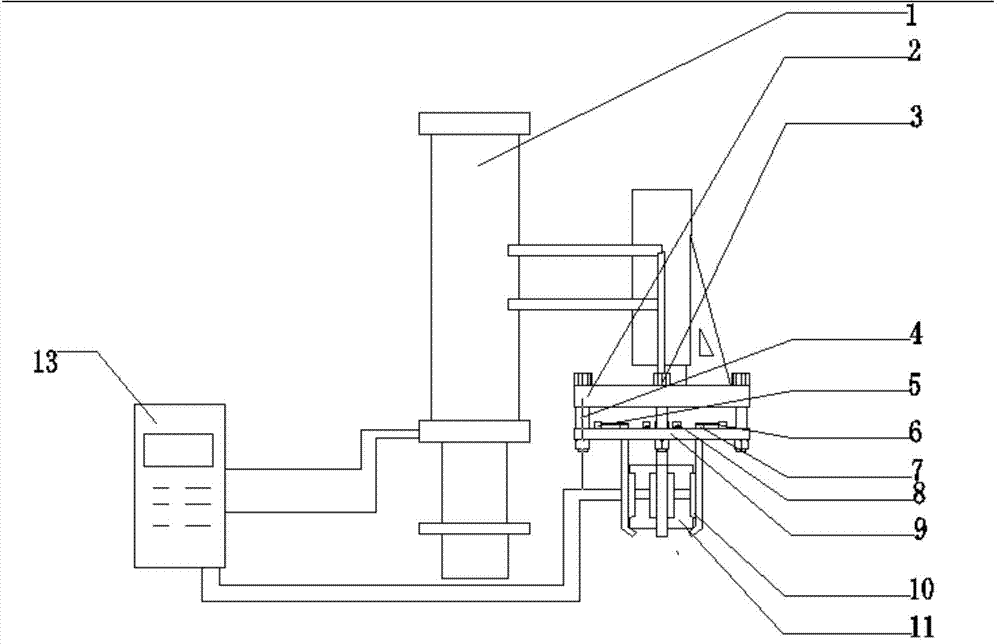

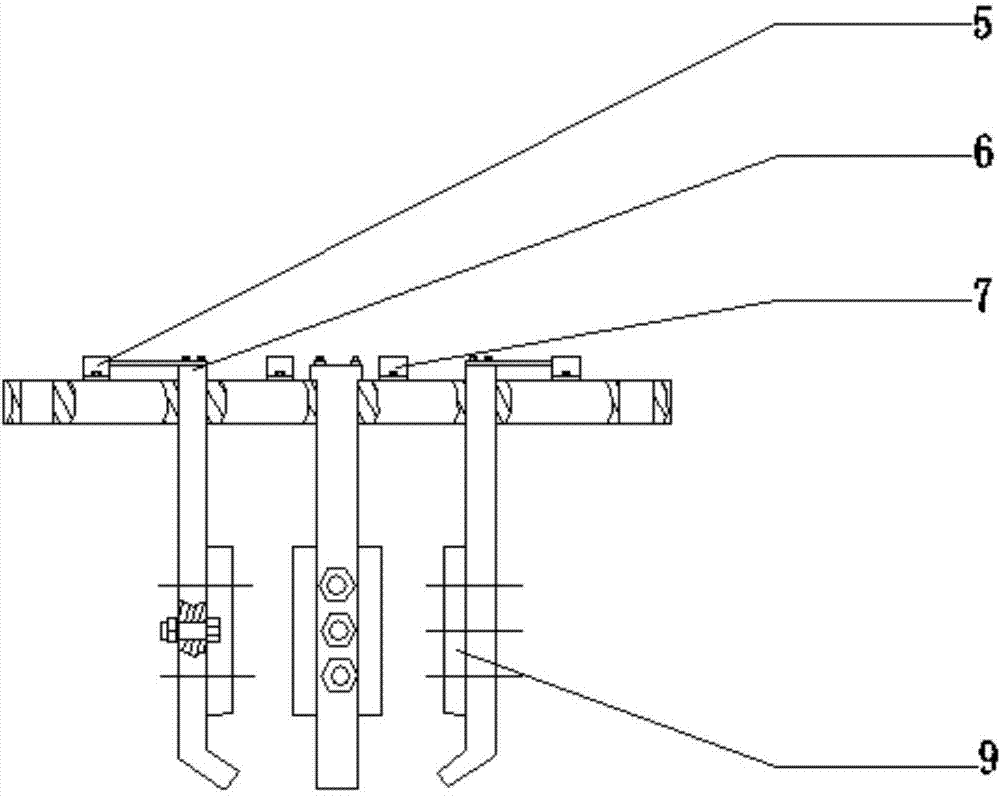

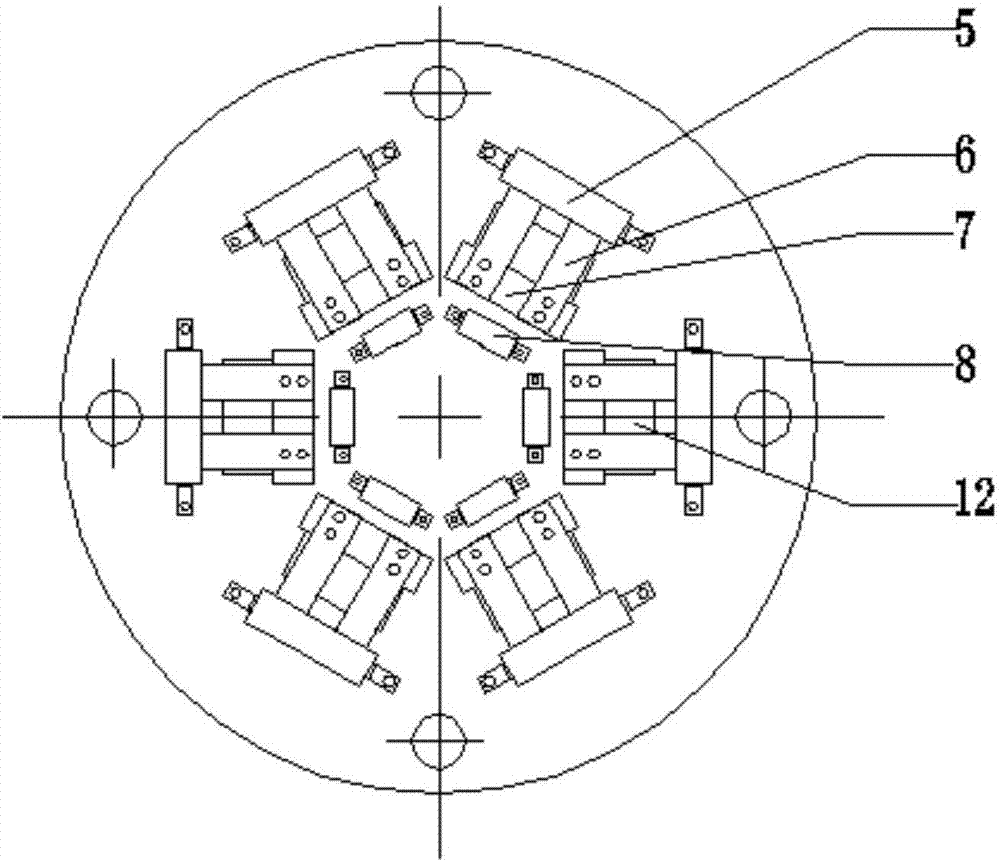

[0019] A kind of radiation preheating tire vulcanization device of the present invention, such as figure 1 , figure 2 and image 3 As shown, the clamping mechanism at the lower end of the tire loading manipulator 1 of the traditional tire shaping and vulcanizing machine is removed, and a kind of radiation preheating tire curing device is installed on the fixed plate 2 of the tire loading manipulator. The device is mainly composed of bolts 3 , clamp block 4, hydraulic controller 5, push rod 6, slider 7, travel switch 8, support frame 9, arc-shaped infrared heating plate 10 and guide rail 12.

[0020] A kind of radiation preheating tire vulcanization device of the present invention, such as figure 1 As shown, the support frame 9 is fixedly installed on the fixed plate 2 of the tire loading manipulator 1 of the tire shaping vulcanizer by the bolt 3, the center of the support frame 9 is coaxial with the center of the fixed plate 2, and the distance between the fixed plate 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com