Segmented mold control device of tire shaping and vulcanizing machine

The technology of a control device and a flexible mold is applied in the field of the flexible mold control device of a tire vulcanizing machine, which can solve the problems of low degree of mechanization, high labor intensity, low safety factor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

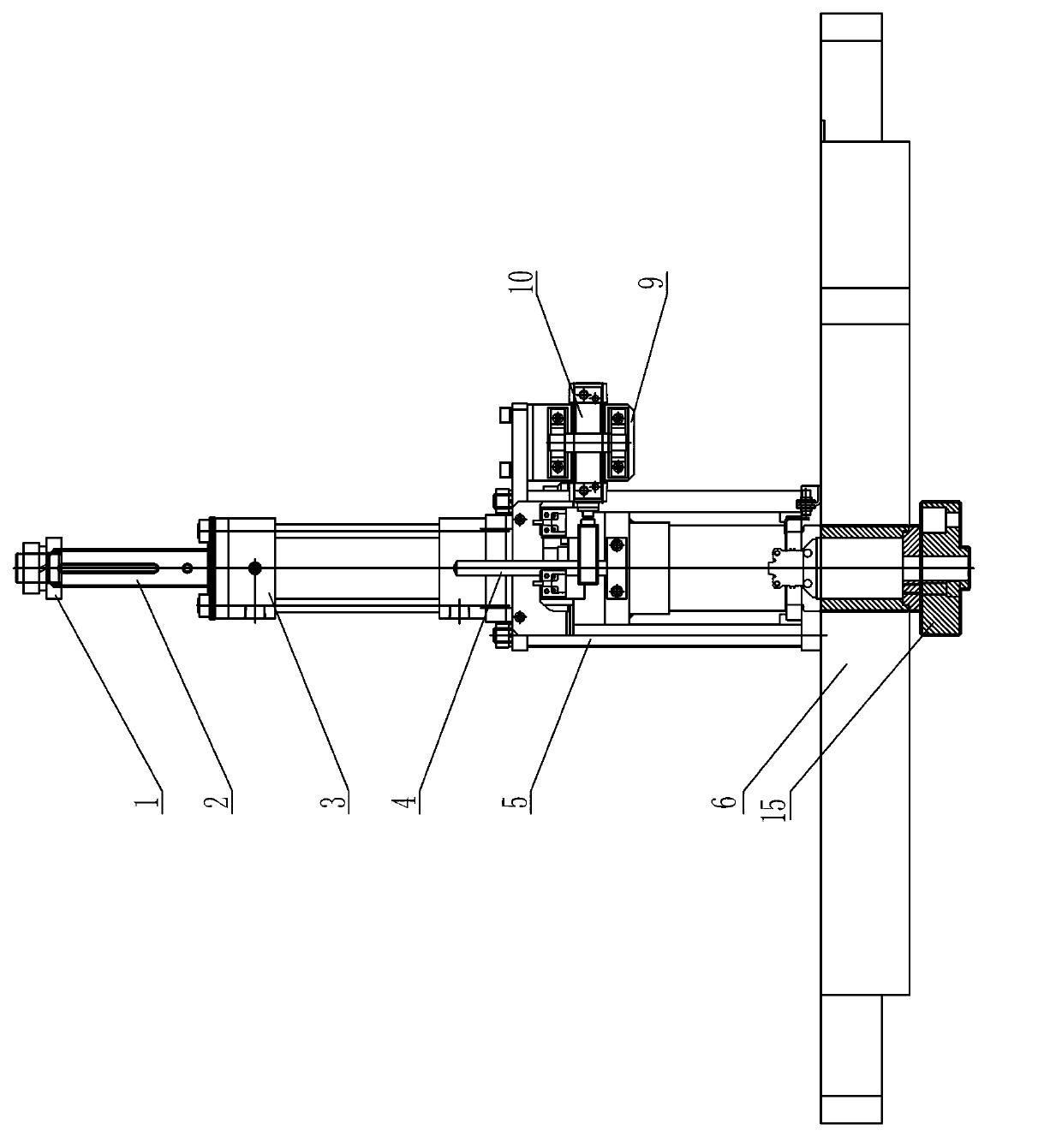

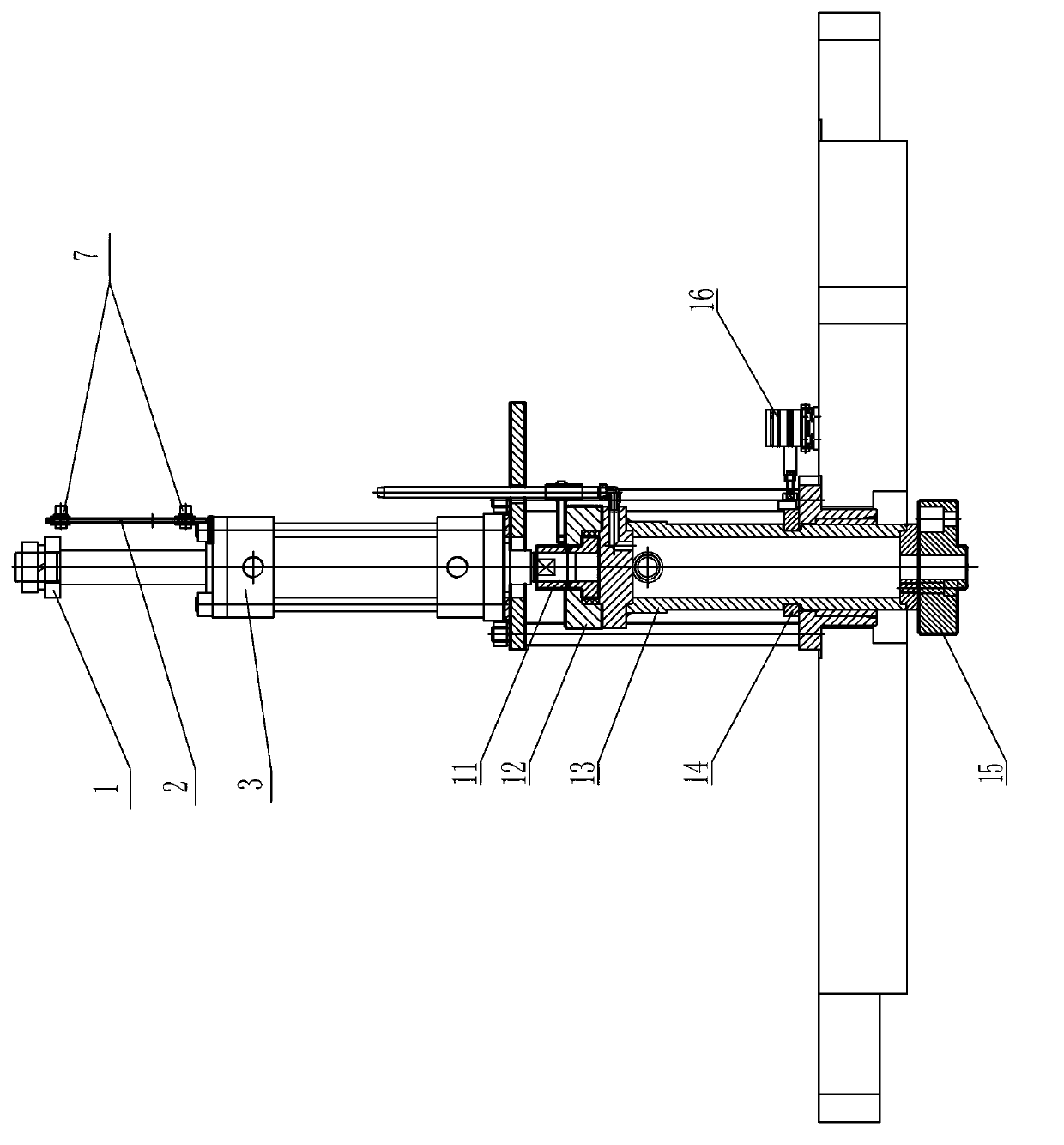

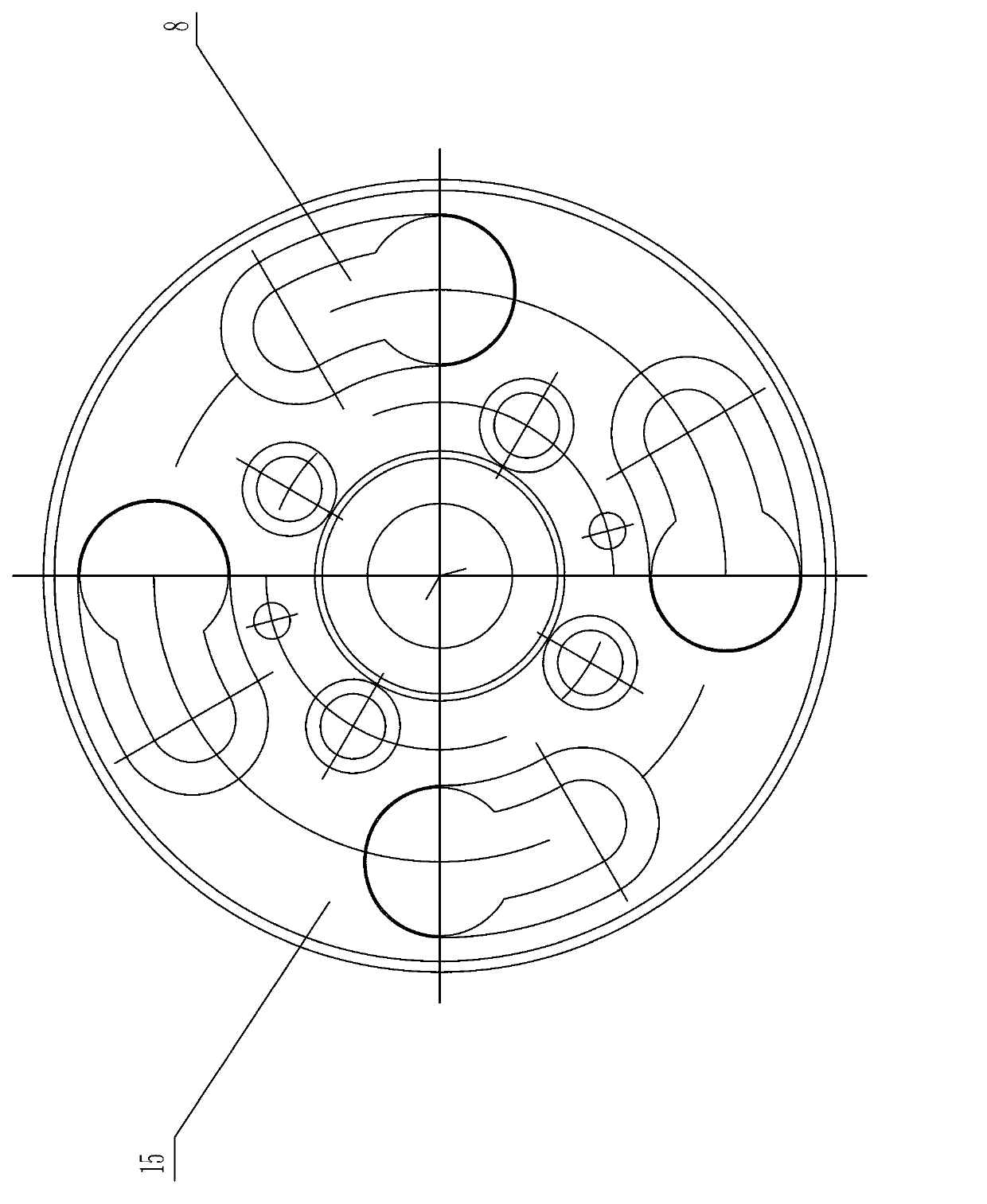

[0019] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

[0020] The active mold operating device of the tire shaping vulcanizer of the present invention is mainly composed of an active mold telescopic operating mechanism, an active mold changing mechanism, a locking mechanism and an active mold telescopic detection mechanism.

[0021] The telescopic manipulating mechanism of the movable mold comprises a double piston rod movable mold oil cylinder 3 , an oil cylinder seat 5 , a rotating shaft 13 and a movable mold flange 15 . The oil cylinder base 5 is a frame structure, fixed on the upper supporting plate 6 of the tire shaping vulcanizer, the active mold oil cylinder 3 is set on the top of the oil cylinder base 5, and the downward piston rod of the active mold oil cylinder 3 extends into the oil cylinder base 5 and is connected to the upper end of the rotating shaft 13 through the combined structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com