Tire designing method and program

A design method and tire technology, applied in tire parts, automobile tire testing, calculation, etc., can solve problems such as inability to design durability and affecting durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a tire design method according to the present invention and a computer-executable program for executing the method will be described in detail according to preferred embodiments shown in the drawings.

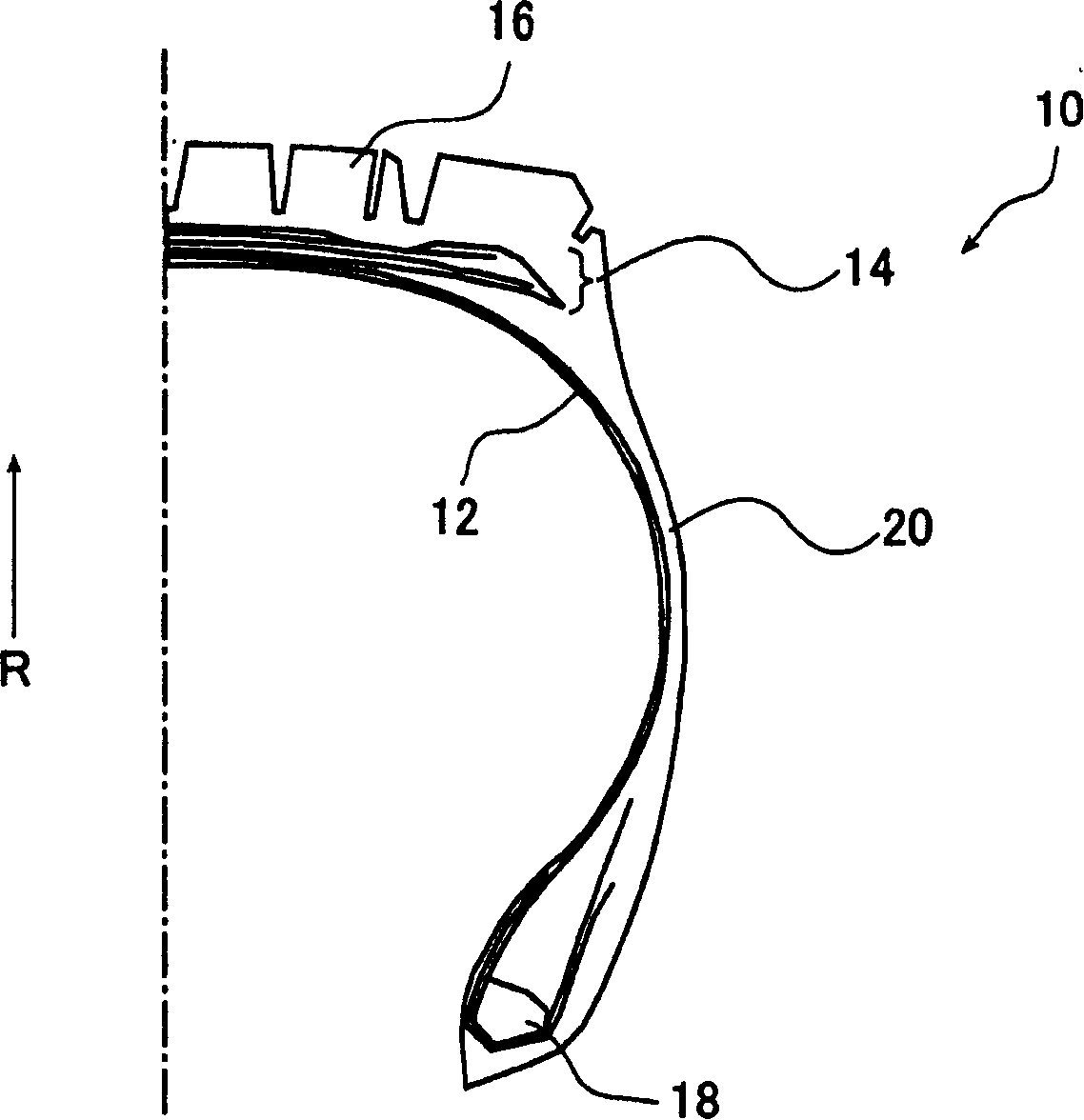

[0030] figure 1 An example of the structure of the cross-sectional shape (tire cross-sectional shape) of a heavy-duty tire (truck / bus tire) is shown.

[0031] A pneumatic tire (hereinafter, referred to as a tire) 10 mainly includes tire constituent members: a carcass member 12 ; an endless belt member 14 ; a tread member 16 ; a bead member 18 ;

[0032] The carcass member 12 is a tire structure obtained by covering a cord material such as steel cord with a rubber material, and the endless belt member 14 is to prevent fastening of the carcass member 12 in the radial direction while fastening the carcass member 12. R expanded tire structure. The tread member 16 is a rubber member on the radially outer side of the endless belt member 14, on which a tread patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com