Full steel wire heavy load radial tire movable mould

A radial tire and flexible mold technology, which is applied in the field of all-steel wire truck radial tire flexible molds, can solve the problems of tire mold use, production coordination and passiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

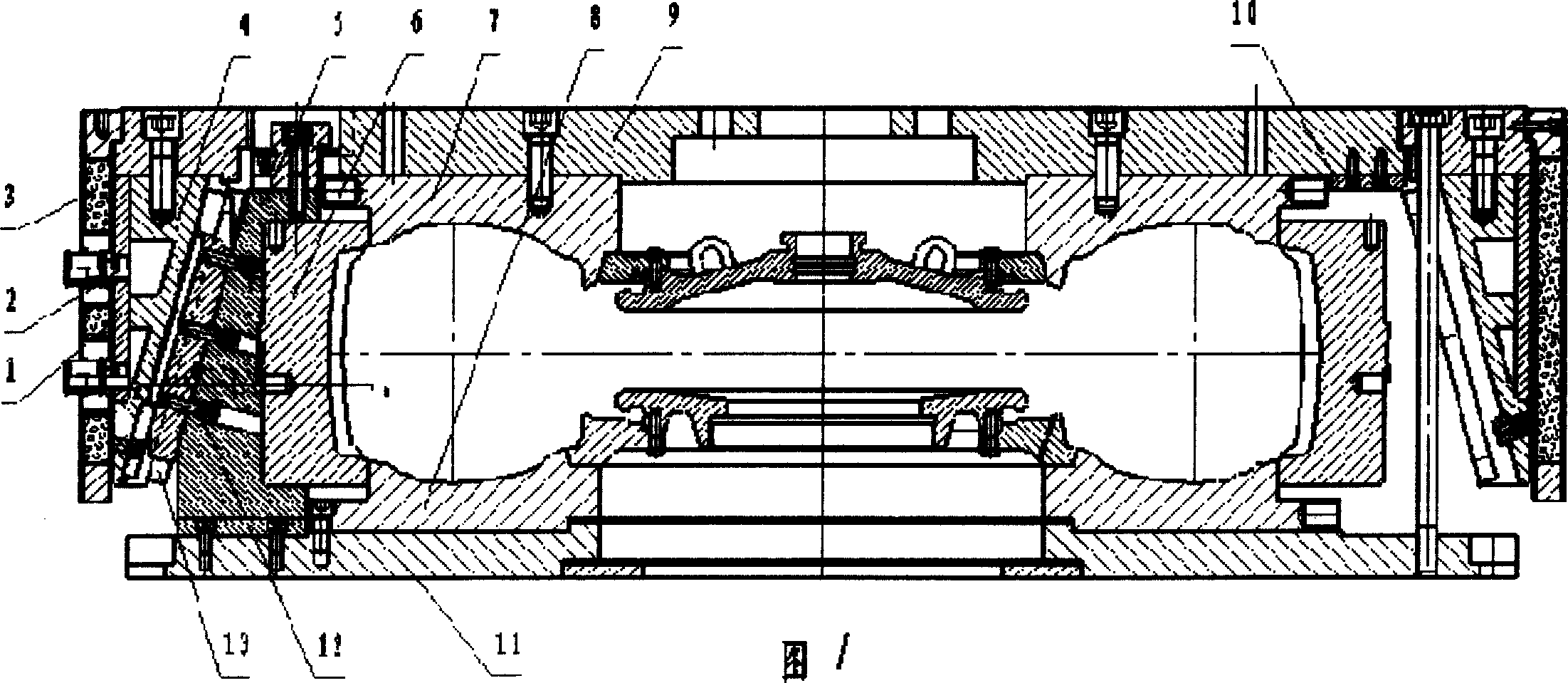

[0010] As shown in Figure 1: an all-steel radial tire active mold, the upper side plate 7 and the lower side plate 8 forming the mold cavity are respectively fixed and placed between the upper cover 9 and the base 11, and the pattern ring 6 is divided into 8~10 The blocks are respectively fixed on the corresponding slide blocks 5, and can realize radial opening and closing with the up and down sliding between the slide block 5 and the middle mold cover 4, so as to realize the finalization of tire vulcanization, demoulding and blanking. 15 ° of planes are processed on the inner cone surface of the middle mold cover 4, and a wear-reducing plate 13 is installed on the plane, and a T-shaped guide block 12 is installed on the back side of the slide block. After the vulcanization of the tire is completed, the middle mold cover 4 moves upward, and the slider 5 and the T-shaped guide block 12 make a relative movement downward along the guide groove formed by the middle mold cover plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com