Single-mold engineering tire shaping vulcanizing machine and engineering tire vulcanizing method

A technology of engineering tires and vulcanizing machines, which is applied to tires, other household appliances, household appliances, etc., and can solve the problems of complex structure, inconvenient operation, and low vulcanization stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

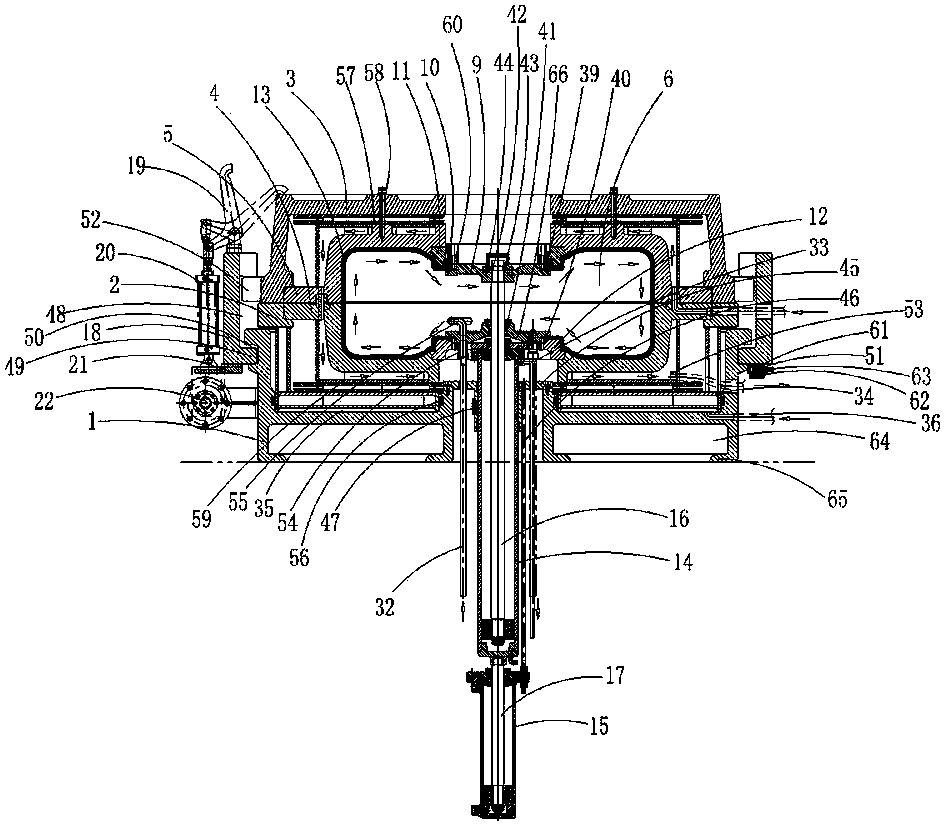

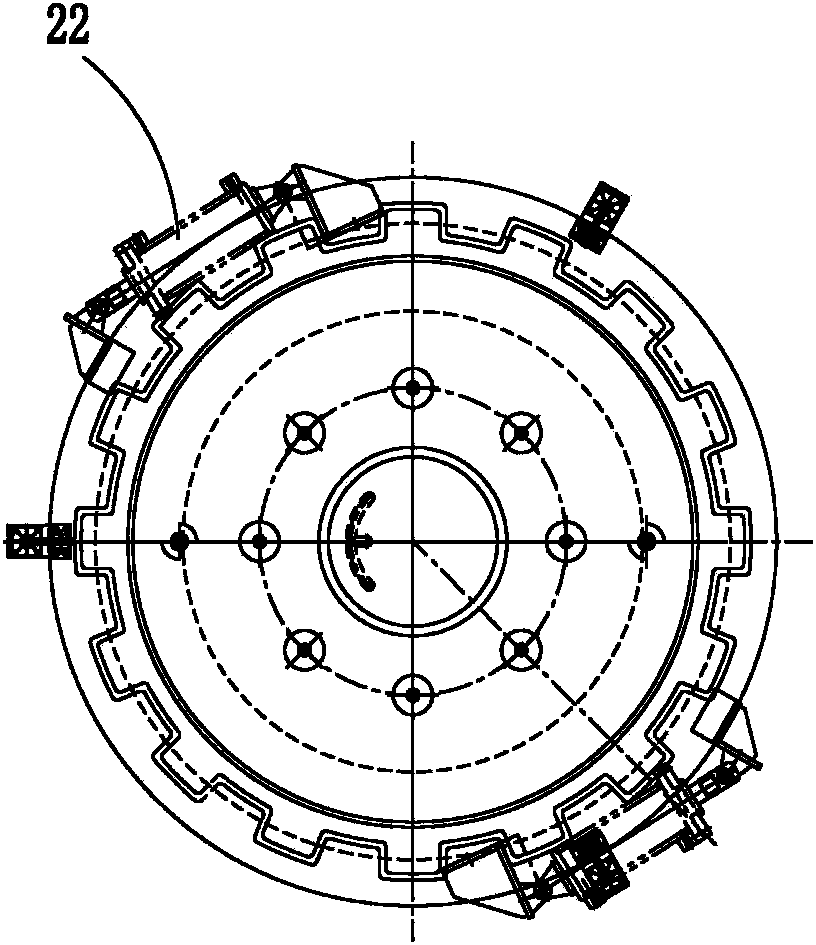

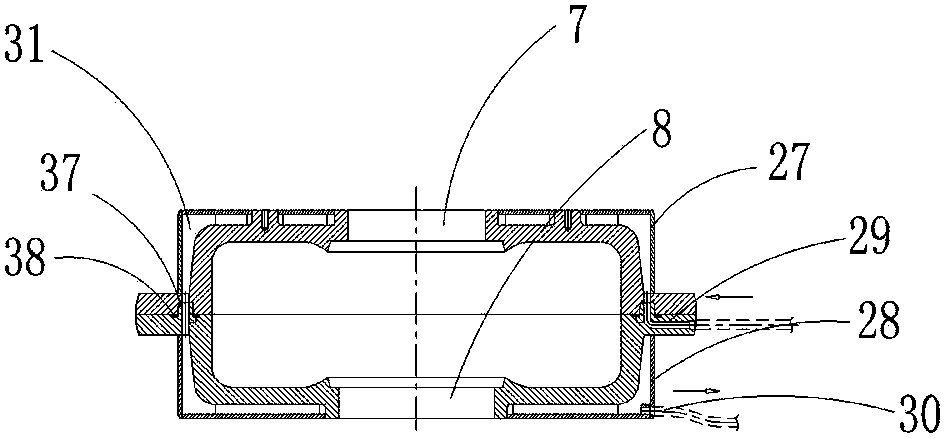

[0057] Embodiment 1: as figure 1 , figure 2 with image 3As shown, a single-mode vulcanizing machine for engineering tire shaping includes a base 1, and the base 1 is provided with a lower tray 2, and the lower tray 2 is provided with an upper tray 3 matched with it. A mold frame mechanism is provided between the upper tray 3 and the lower tray 2, and a capsule clamping mechanism is provided in the mold frame mechanism, and the capsule clamping mechanism is controlled by an oil cylinder lifting mechanism. The upper tray 3 and the The lower tray 2 is pressurized and fixed by a mold clamping and pressing device, and the mold clamping and pressing device is locked by a locking device. The mold base mechanism is provided with a steam circuit mechanism outside, and the capsule clamping mechanism There is a vulcanization cycle mechanism connected with it. The base 1 is provided with a pressurized mold clamping mechanism. The pressurized mold clamping mechanism pushes the upp...

Embodiment 2

[0089] Embodiment 2: A kind of vulcanization method of engineering tire, operates according to the following steps:

[0090] (1) Install the vulcanizing bladder:

[0091] The upper ring lift cylinder 14 descends, clamps the upper mouth of the curing bladder 13 between the upper chuck 9 and the upper die chuck 10, clamps the lower mouth of the curing bladder 13 between the lower chuck 66 and the lower die 12, Put the tire embryo into the embryo installation cavity 6;

[0092] (2) Input the setting steam into the vulcanization bladder:

[0093] Input the shaped steam into the vulcanizing bladder 13 through the internal pressure inlet pipe 32, and the orifice in the circuit is opened, and the diameter of the orifice is 8mm, forming a cycle; Adjust the valve phase control, the time for setting steam is 9 minutes, and the temperature of setting steam is 170°C;

[0094] (7) Mold positioning:

[0095] Mount the upper order mold 11 on the upper order mold chuck 10, hoist the ...

Embodiment 3

[0120] Embodiment 3: a kind of engineering tire vulcanization method, operate according to the following steps:

[0121] (1) Install the vulcanizing bladder:

[0122] The upper ring lift cylinder 14 descends, clamps the upper mouth of the curing bladder 13 between the upper chuck 9 and the upper die chuck 10, clamps the lower mouth of the curing bladder 13 between the lower chuck 66 and the lower die 12, Put the tire embryo into the embryo installation cavity 6;

[0123] (2) Input the setting steam into the vulcanization bladder:

[0124] Input the shaped steam into the vulcanizing bladder 13 through the internal pressure inlet pipe 32, and the orifice in the circuit is opened, and the diameter of the orifice is 8mm, forming a cycle; Adjust the valve phase control, the time for setting steam is 10 minutes, and the temperature of setting steam is 175°C;

[0125] (9) Mold positioning:

[0126] Mount the upper order mold 11 on the upper order mold chuck 10, hoist the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com