Tyre shape detecting device and tyre shape detecting method

A technology of detection device and detection method, which is applied in the direction of measurement device, optical device, instrument, etc., can solve the problem of not being able to obtain a clear image of linear light, and achieve the effect of high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the embodiments of the present invention will be described with reference to the drawings in order to understand the present invention. In addition, the following embodiment is only an example of concretely implementing the present invention, and does not limit the technical scope of the present invention.

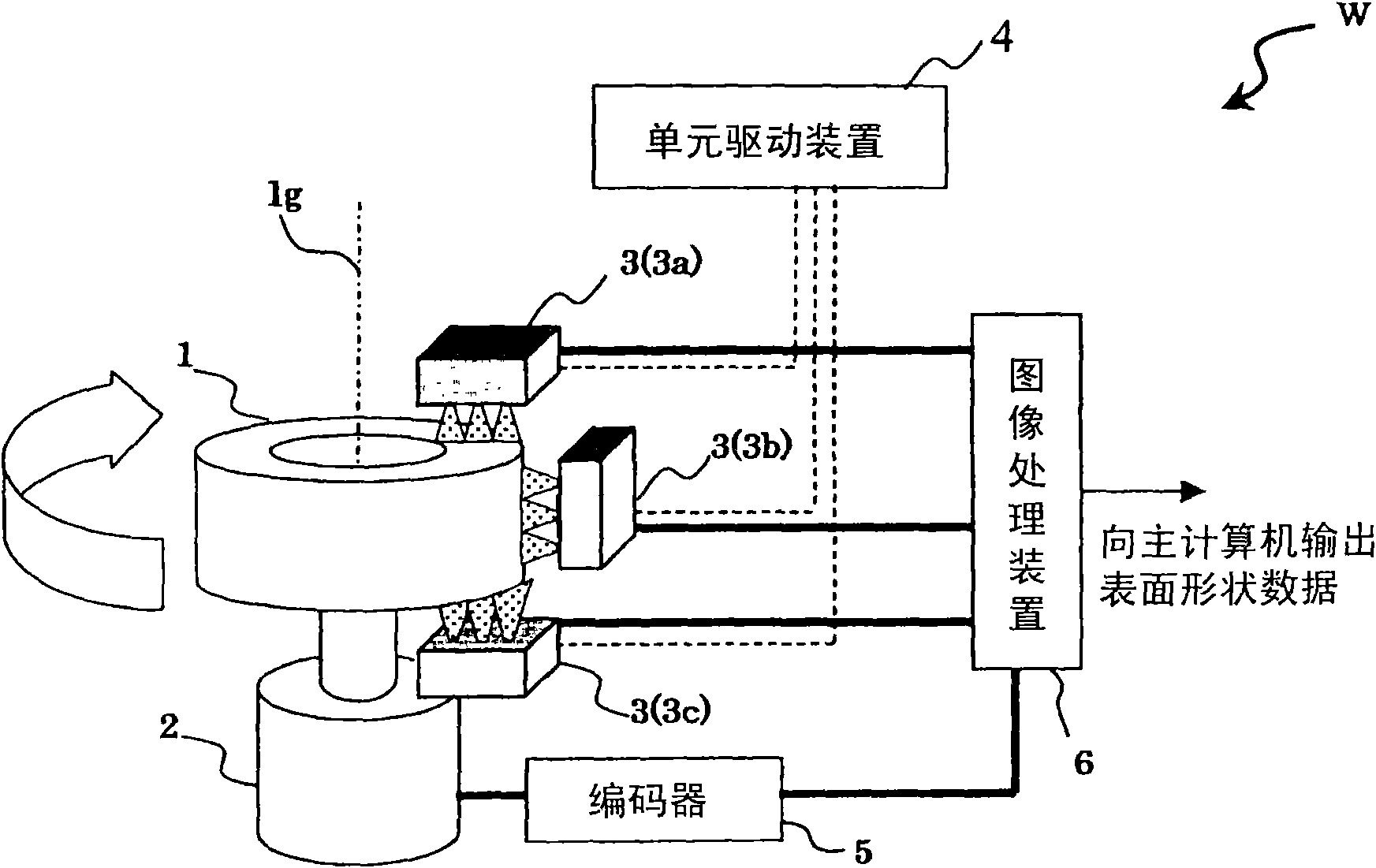

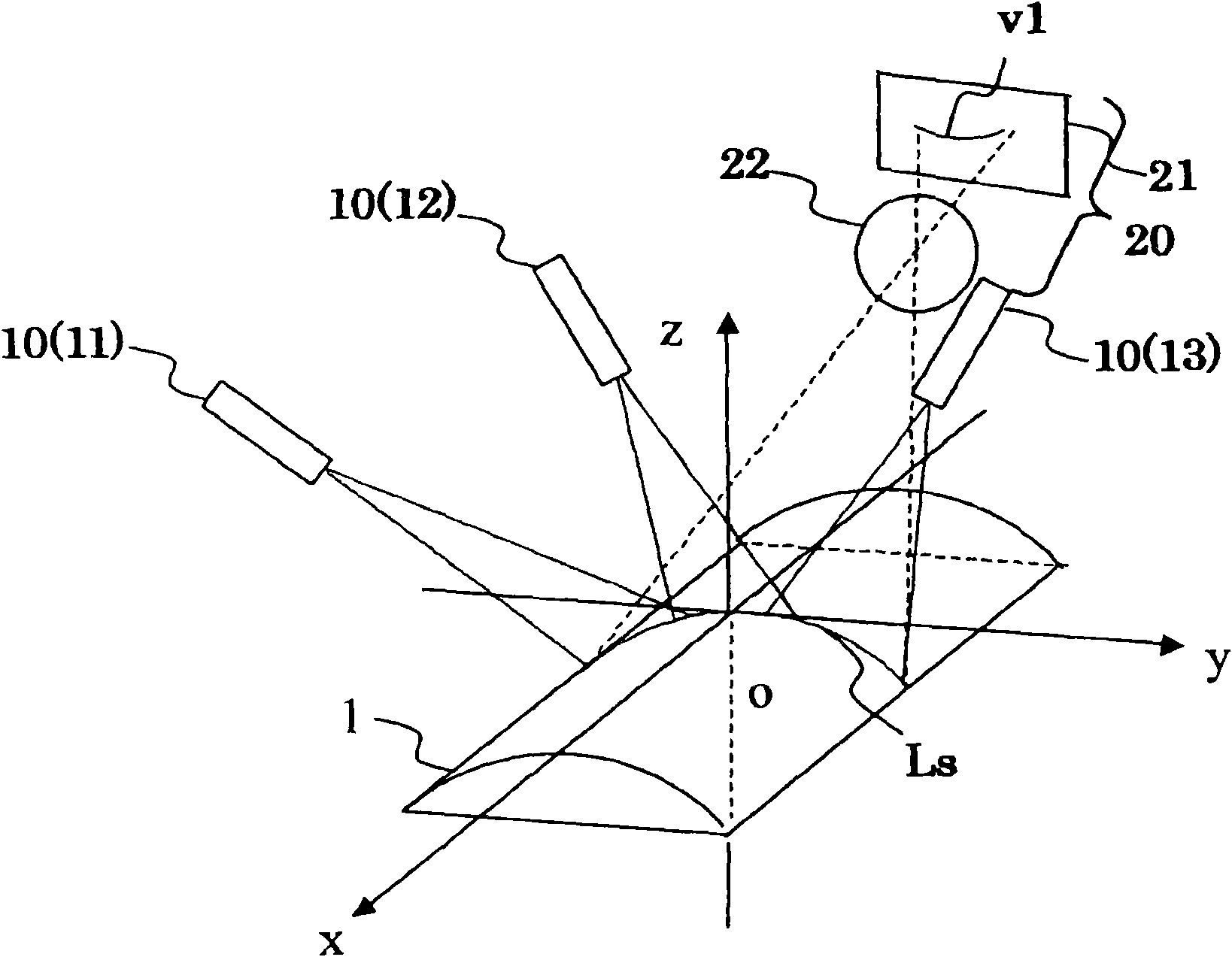

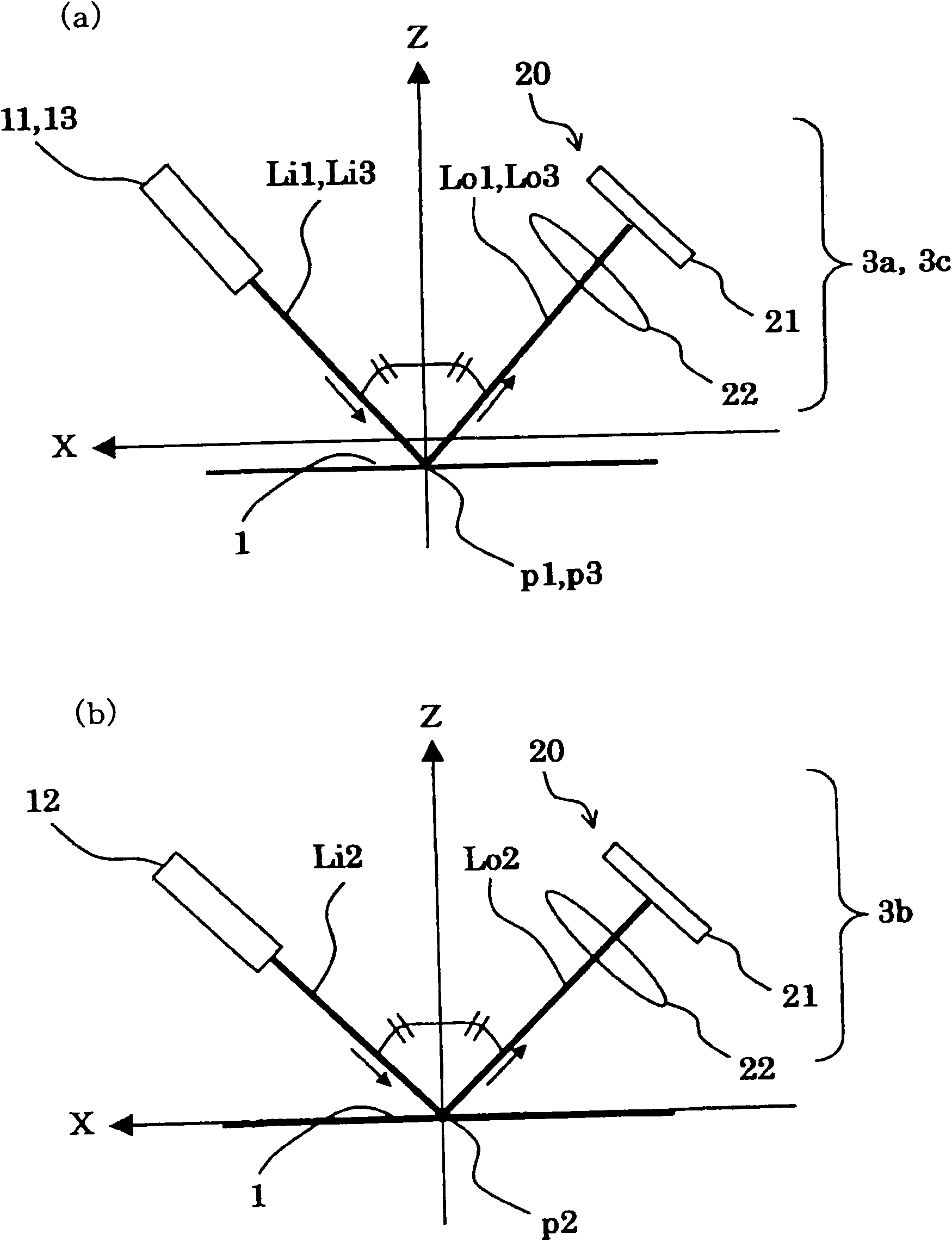

[0053] Here, figure 1 Is a diagram showing a schematic configuration of a tire shape detection device W according to an embodiment of the present invention, figure 2 It is a diagram schematically showing the three-dimensional arrangement of light sources and cameras in the sensor unit included in the tire shape detection device W, image 3 It is a diagram schematically showing the arrangement of linear light sources and cameras in the sensor unit when viewed from a specific direction (Y-axis direction), Figure 4 It is a diagram schematically showing the arrangement of the linear light source and the camera in the sensor unit when viewed from a direction pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com