Method and device for preparing lithium iron phosphate precursor by high-temperature superheated steam dry method

A technology of lithium iron phosphate and superheated steam, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of long grinding time, large equipment wear, and high equipment investment costs, so as to reduce the drying process, reduce production costs, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

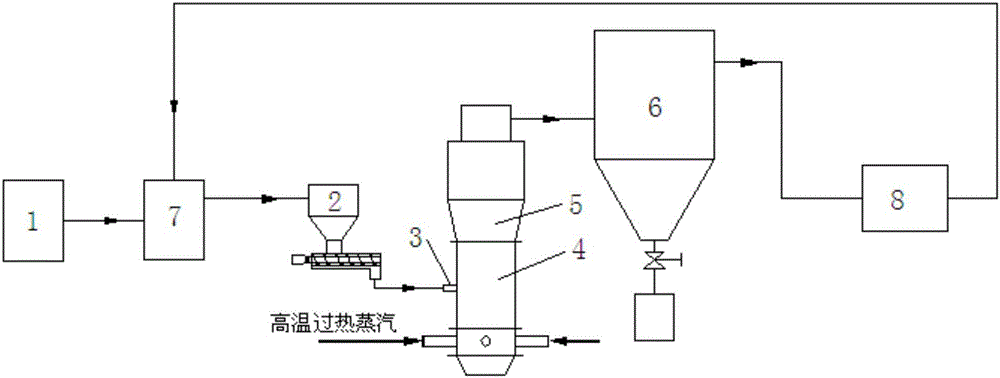

[0031] A device for preparing lithium iron phosphate precursors by dry method using high-temperature superheated steam, including a lithium iron phosphate precursor material mixer 1, a material delivery pump 2, an atomizing nozzle 3, a steam kinetic energy mill 4, an ultra-fine classifier 5 and a steam Dust collector 6, the atomizing nozzle 3 is arranged on the steam kinetic energy 4 grinding chamber wall, the lithium iron phosphate precursor material mixer 1 is connected with the atomizing nozzle 3 through the material delivery pump 2, the steam kinetic energy mill 4, super The subdivision classifier 5 and steam dust collector 6 are sequentially connected, and the material delivery pump 2 is a single-screw pump.

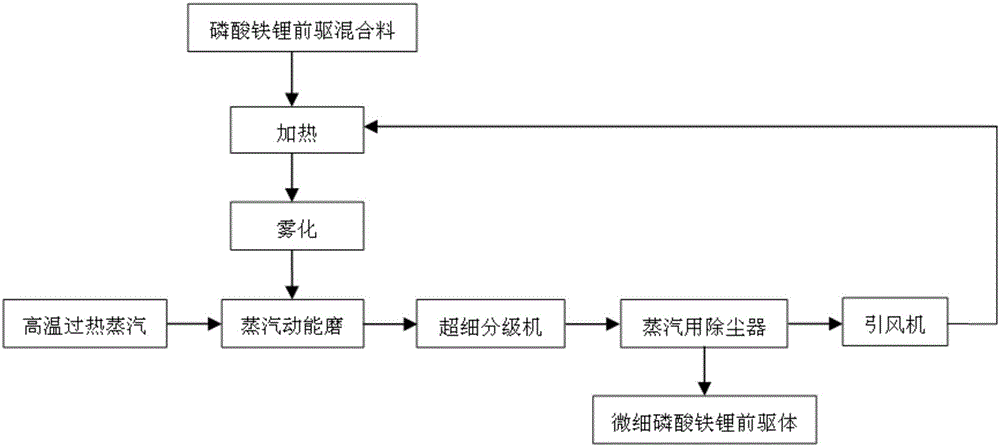

[0032] In combination with the above-mentioned device, a method for preparing a lithium iron phosphate precursor by a high-temperature superheated steam dry method comprises the following steps:

[0033] (1) wet stirring in the lithium iron phosphate precursor mater...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the atomizing nozzle 3 is arranged in the center of the crushing chamber of the steam kinetic energy mill 4 .

Embodiment 3

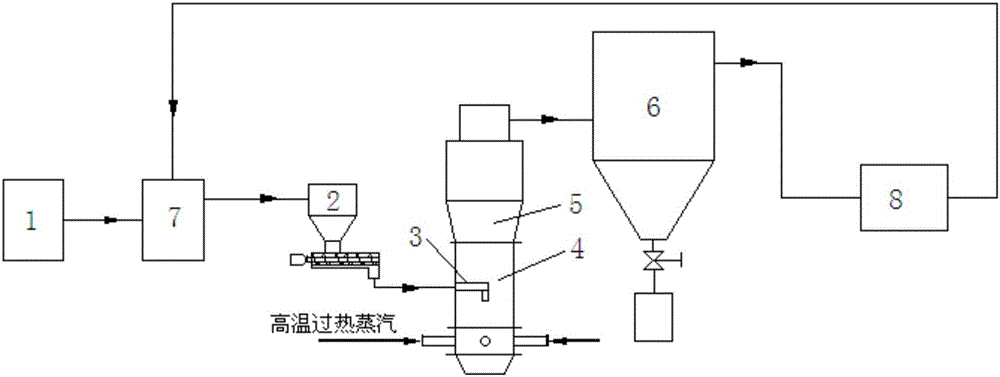

[0040] Embodiment 3, on the basis of Embodiment 1 or 2, also includes a material heater 7 and an induced draft fan 8, the lithium iron phosphate precursor material mixer 1, material heater 7, material delivery pump 2 and atomizing nozzle 3 Connected in sequence, the steam outlet of the steam dust collector 6 is connected with the heat source inlet of the material heater 7 through the induced draft fan 8 .

[0041] Use the high-temperature superheated steam separated by the dust collector 6 as the heat source for heating the lithium iron phosphate precursor mixture, and use the induced draft fan 8 to introduce it into the material heater 7, and the wet-stirred lithium iron phosphate precursor mixture first passes through the material heater 7 heating, and then transported to the atomizing nozzle 3 by the material delivery pump 2 for atomization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com