Method for preparing small-fraction filling composite masterbatch through semi-open type superheated steam spray-drying method

A technology of spray drying and superheated steam, which is applied in the field of preparing small-volume filled composite masterbatches, can solve problems such as low volume heat transfer coefficient and thermal efficiency, large power consumption, and environmental protection issues, and achieve excellent air permeability resistance and reduce Waste of energy, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

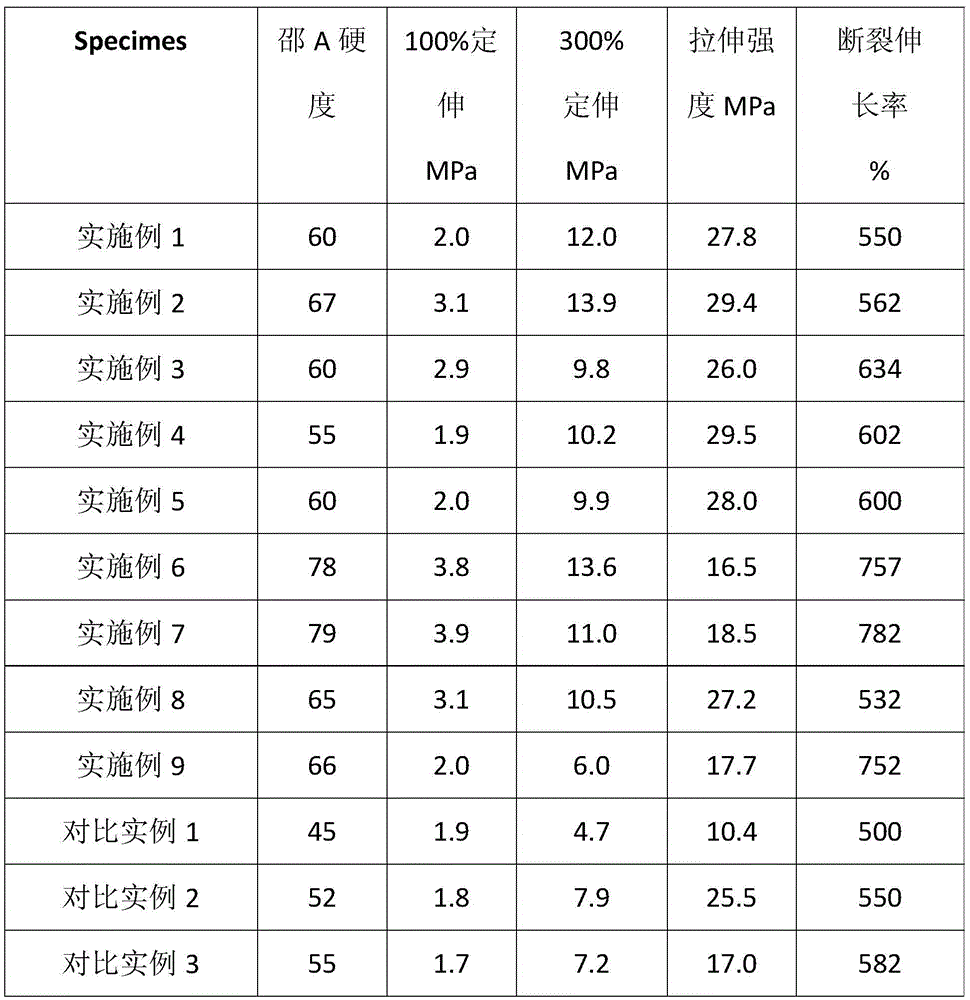

Examples

Embodiment 1

[0035] Add 5 g of carbon black to 495 g of water, stir to obtain a solid content of 1% carbon black aqueous solution, mix with 500 g of field natural latex with a solid content of 20%, add 3 g of zinc oxide and 1 g of stearic acid after stirring.

[0036] The prepared mixed slurry is passed into a semi-open superheated steam spray drying tower, the atomized particle size is controlled to 10 μm, the drying medium is superheated steam at 140°C, the inlet temperature of the spray drying equipment is 180°C, and the outlet air temperature is Pass through a 20um sieve at 100°C to collect the dried carbon black / natural rubber nanocomposite masterbatch. The rubber mixing formula is 109phr of the above-mentioned masterbatch, 1.2phr of accelerator CZ, 40101phr of anti-aging agent, and 2phr of sulfur. Then the rubber is mixed, vulcanized, and tested for mechanical properties.

Embodiment 2

[0038] Add 20 g of carbon black into 80 g of water, stir to obtain a solid content of 20% carbon black aqueous solution, mix with 333 g of field natural latex with a solid content of 30%, add 5 g of zinc oxide and 3 g of stearic acid after stirring.

[0039] The prepared mixed slurry is passed into the semi-open superheated steam spray drying tower, the atomized particle size is controlled to 100 μm, the drying medium is superheated steam at 250 °C, the inlet temperature of the spray drying equipment is 300 °C, and the outlet air temperature is 120°C, pass through a 100um sieve plate, collect the carbon black / natural rubber nanocomposite masterbatch that has been calendered and dried into blocks, and the mixing formula is 128phr of the above masterbatch, and the rest of the steps are as in Example 1.

Embodiment 3

[0041] Add 20 g of white carbon black into 80 g of water, stir evenly to obtain a white carbon black aqueous solution with a solid content of 20%. Mix with 250g of neoprene latex with a solid content of 40%, add latex consumption 5g of zinc oxide and 1g of stearic acid after stirring.

[0042] The prepared mixed slurry is passed into the semi-open superheated steam spray drying tower, the atomized particle size is controlled to 80 μm, the drying medium is superheated steam at 200 °C, the inlet temperature of the spray drying equipment is 250 °C, and the outlet air temperature is Pass through a 100um sieve plate at 110°C to collect the dried and calendered white carbon black / chloroprene rubber nanocomposite masterbatch. The rubber mixing formula is 126phr of the above-mentioned masterbatch, and the remaining steps are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com