Positive electrode material layer, preparation method thereof, positive plate and battery

A technology of positive electrode material layer and positive electrode sheet, which is applied in the field of positive electrode material layer, its preparation, positive electrode sheet and battery, can solve the problem that it is difficult to mix the positive electrode material with the conductive agent and the binder uniformly, the requirement of the roller shaft material is too high, and the difficulty Press into a self-supporting film and other problems to achieve the effect of eliminating the drying process, avoiding post-processing and recycling, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

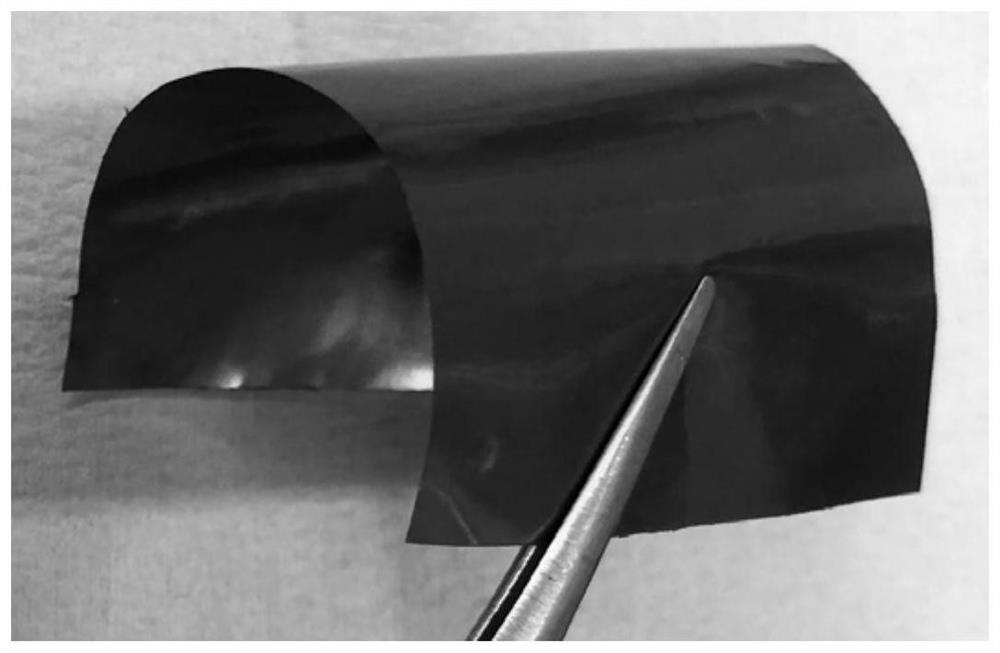

[0055] Add 9g of carbon-coated nickel-cobalt lithium manganese oxide and 0.2g of conductive agent acetylene black into the blender, stir at a low speed (100rpm) for 10 minutes, mix well, then add 0.8g of polytetrafluoroethylene, and stir at a low speed (100rpm) 10 minutes, mix evenly, high-speed (10000rpm) pulse stirring for 30 minutes, carry out the fiberization process. The mixed powder is put into a roller press, and hot rolled at 150° C. to form a self-supporting film, and repeatedly rolled to a certain compaction density to obtain a self-supporting positive electrode material layer (see figure 1 ), and finally the self-supporting positive electrode material layer is thermally rolled and laminated with the current collector to obtain the positive electrode sheet.

[0056] Among them, carbon-coated nickel-cobalt-manganese oxide lithium includes nickel-cobalt-manganese oxide lithium (NiCoMn) 1 / 3 o 2 , and coated in the Li(NiCoMn) 1 / 3 o 2 The carbon coating layer on the s...

Embodiment 2

[0058] Add 8.5g of carbon-coated nickel-cobalt lithium manganese oxide and 0.5g of conductive agent acetylene black into the blender, stir at a low speed (300rpm) for 10 minutes, mix well, then add 10g of polytetrafluoroethylene, and stir at a low speed (300rpm) 10 minutes, mix evenly, high-speed (16000rpm) pulse stirring for 20 minutes, carry out the fiberization process. The mixed powder is put into a roller press, hot rolled at 150°C to form a self-supporting film, repeatedly rolled to a certain compaction density, and finally hot rolled with a current collector to obtain a positive electrode sheet.

[0059] Among them, carbon-coated nickel-cobalt-manganese oxide lithium includes nickel-cobalt-manganese oxide lithium (NiCoMn) 1 / 3 o 2 , and coated in the Li(NiCoMn) 1 / 3 o 2 The carbon coating layer on the surface, the content of the carbon coating layer in the carbon-coated nickel-cobalt lithium manganese oxide is 3%, and the type of the carbon coating layer is natural gra...

Embodiment 3

[0061] Add 8.0g of carbon-coated nickel-cobalt lithium manganese oxide and 0.2g of conductive agent Super-P into the mixer, stir at low speed (200rpm) for 10 minutes, mix well, then add 0.8g of polytetrafluoroethylene, pulse at low speed (200rpm) Stirring for 10 minutes, mixing evenly, high-speed (17000rpm) pulse stirring for 30 minutes, fiberization process. The mixed powder is put into a roller press, hot rolled at 130°C to form a self-supporting film, repeatedly rolled to a certain compaction density, and finally hot rolled with a current collector to obtain a positive electrode sheet.

[0062] Among them, carbon-coated nickel-cobalt-manganese oxide lithium includes nickel-cobalt-manganese oxide lithium (NiCoMn) 1 / 3 o 2 , and coated in the Li(NiCoMn) 1 / 3 o 2 The carbon coating layer on the surface, the content of the carbon coating layer in the carbon-coated nickel-cobalt lithium manganese oxide is 8%, and the type of the carbon coating layer is artificial graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com