Method for preparing cobaltosic oxide with large grain size and high safety

A technology of cobalt tetroxide and large grain size, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of poor electrochemical performance of the battery, difficult to obtain industrial application, complicated process, etc., and achieves low cost and large grain size. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

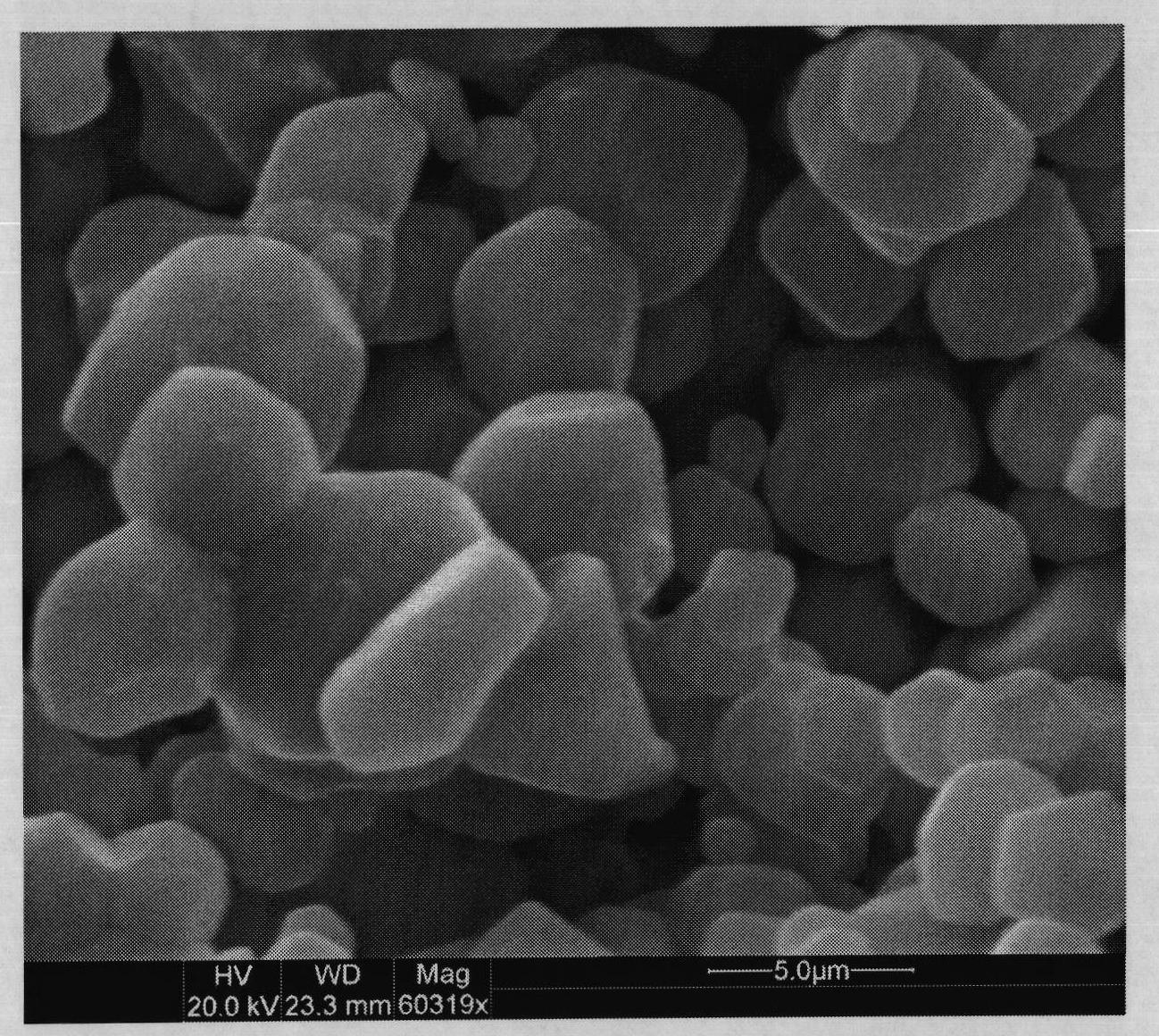

[0033] With deionized water, industrial-grade cobalt sulfate is prepared into a solution with a cobalt concentration of 70g / L, ammonium bicarbonate is made into a precipitant solution with a concentration of 120g / L, and the cobalt solution and the precipitant solution are in molar ratio, cobalt : precipitating agent=1.0: 3.0, add reaction vessel with co-current feeding method, control feeding speed is 15ml / min, the synthetic reaction temperature is 60 ℃, and reaction pH value is 7.3, and stirring speed is 400rpm, makes precursor, will The precursor was washed with deionized water at 80°C and then dehydrated. The water content of the filter cake was 25%. At room temperature, after crushing and grading, metal foreign matter is removed by an iron remover to obtain a spherical cobalt tetraoxide powder, D 10 : 2.26 μm, D 50 : 8.16 μm, D 97 : 12.45μm, TD: 2.98g / cm 3 , and its SEM image is figure 1 shown.

Embodiment 2

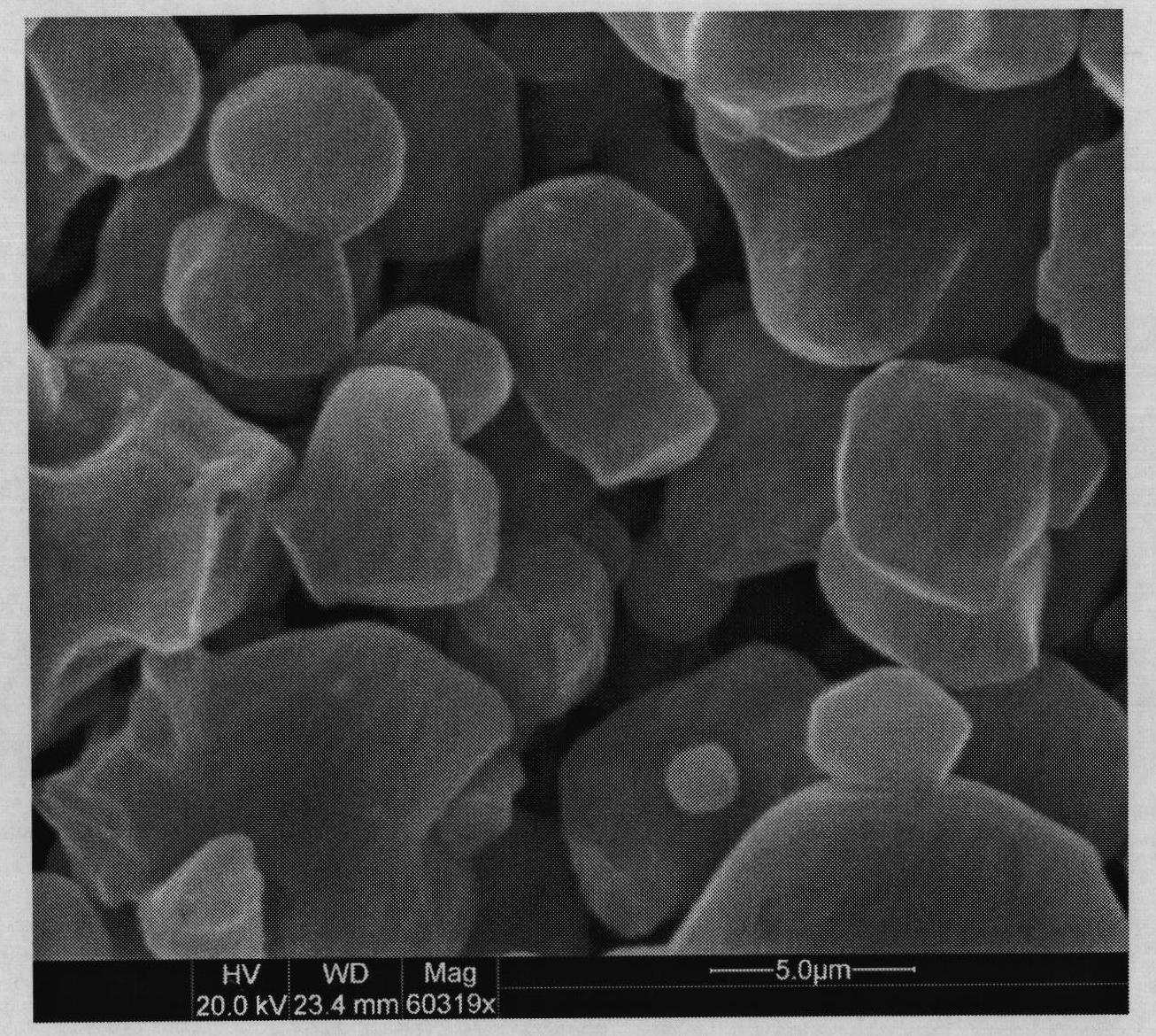

[0035]With deionized water, the cobalt nitrate of technical grade is mixed with the solution that cobalt concentration is 80g / L, and sodium carbonate is made into the precipitant solution that concentration is 100g / L, with cobalt solution and precipitant solution in molar ratio, cobalt: Precipitating agent=1.0:3.1, add the reaction vessel with co-current feeding method, control the feeding speed to be 12ml / min, the synthetic reaction temperature is 80°C, the reaction pH value is 8.5, and the stirring speed is 500rpm to prepare the precursor. The body is washed with deionized water at 90°C and then dehydrated. The water content of the filter cake is 24%. It is directly loaded into a bowl, sent to a roasting furnace for 9 hours at 300°C to 950°C, cooled naturally to below 400°C, and then cooled to room temperature. After pulverization and classification, metal foreign matter is removed by iron remover to obtain spherical cobalt tetraoxide powder, D 10 : 3.55 μm, D 50 : 10.90 μm...

Embodiment 3

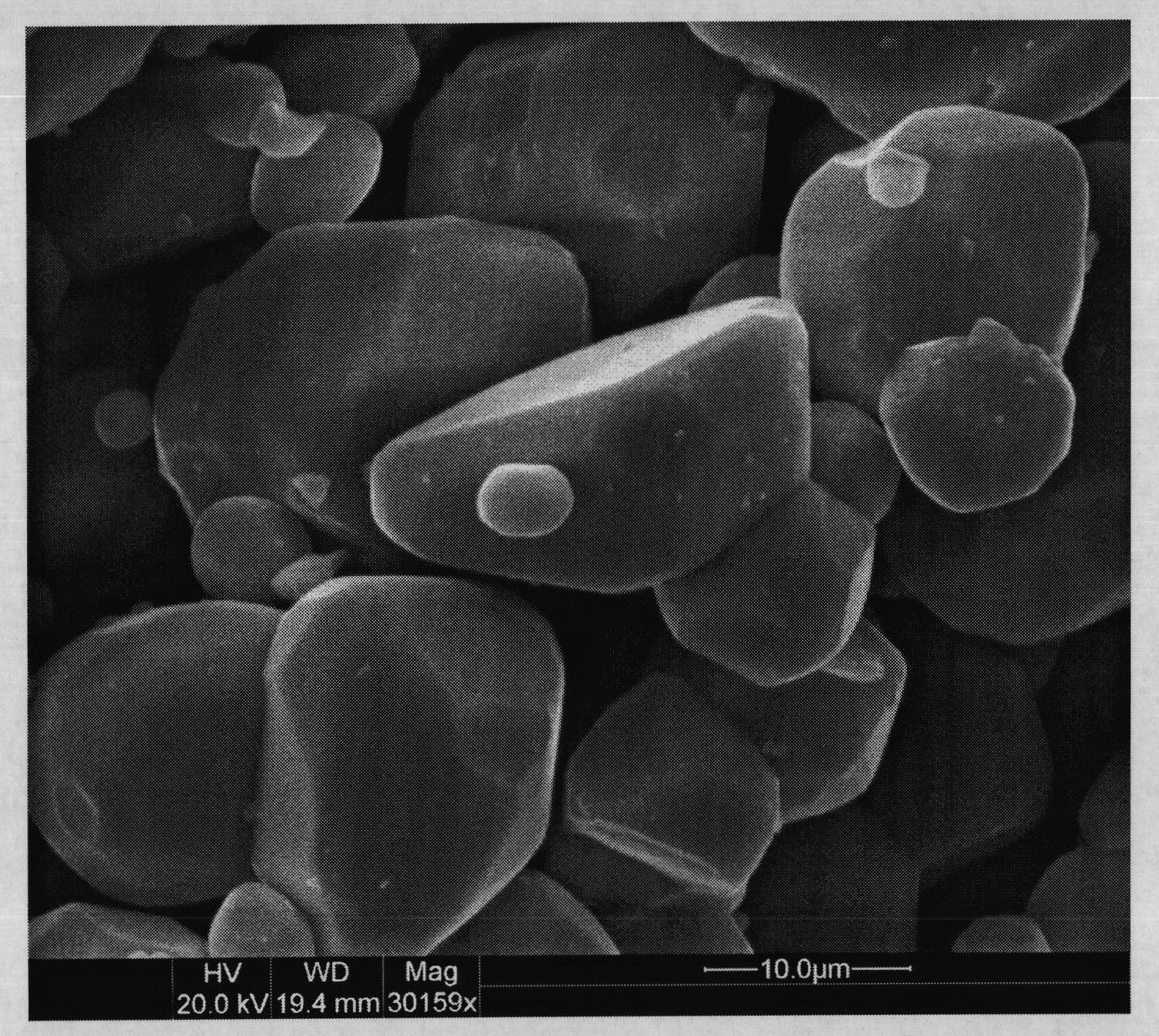

[0037] With deionized water, industrial-grade cobalt chloride is formulated into a solution with a cobalt concentration of 90g / L, ammonium carbonate is made into a precipitant solution with a concentration of 100g / L, and the cobalt solution and the precipitant solution are in molar ratio, cobalt : precipitating agent=1.0: 3.8, add reaction vessel with co-current feeding method, control feeding speed is 8ml / min, the synthetic reaction temperature is 100 ℃, and reaction pH value is 9.0, and stirring speed is 800rpm, makes precursor, will The precursor is washed with deionized water at 100°C and then dehydrated. The water content of the filter cake is 24%. Put it in a bowl directly, send it to a roasting furnace for 10 hours at 300°C to 1000°C, cool it naturally to below 400°C, and then cool it down to room temperature. , after crushing and grading, metal foreign matter is removed by iron remover to obtain spherical cobalt tetraoxide powder, D 10 : 3.16 μm, D 50 : 13.59 μm, D 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com