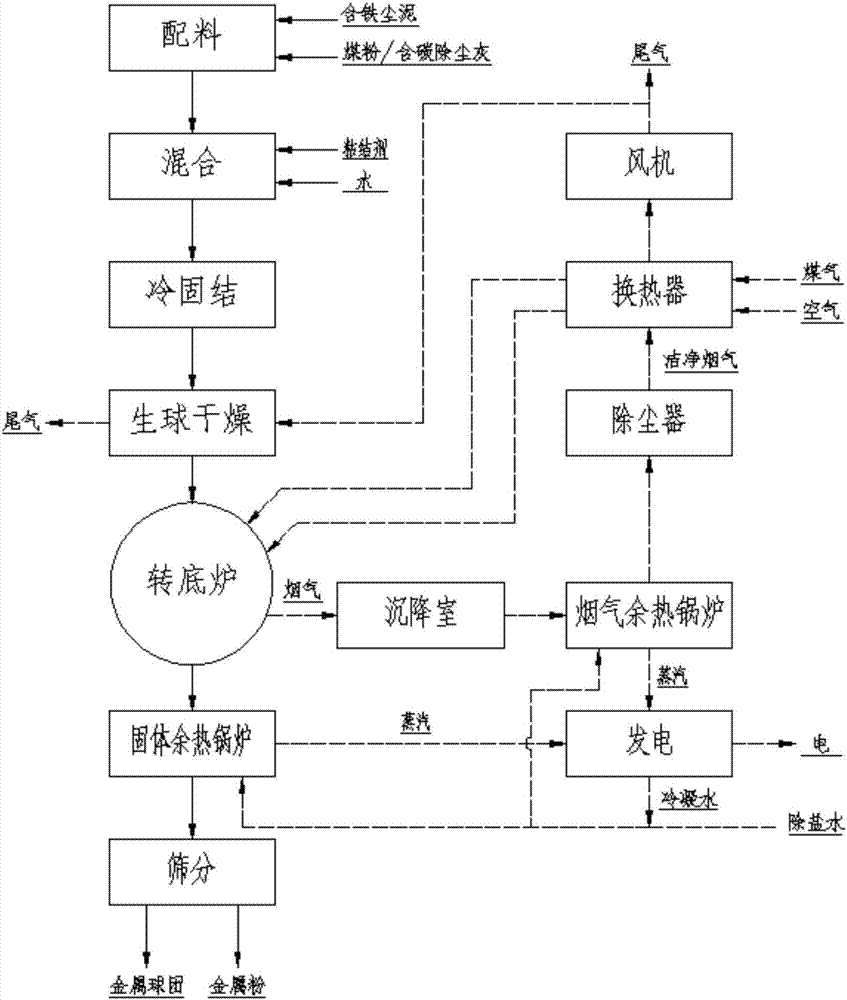

Rotary hearth furnace treatment process for iron-containing dust slime

A treatment process and rotary hearth furnace technology, applied in the field of metallurgy, can solve problems such as affecting the smooth running of the rotary hearth furnace process, poor adaptability to flue gas working conditions, and increasing system complexity, so as to reduce drying links and increase energy utilization. , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A, mix iron-containing dust sludge, metallurgical dedusting dry ash (blast furnace bag ash, cast iron dust removal ash, etc.) according to the C / O molar ratio of 1.1, and control the moisture content of the ingredients to ≤10%;

[0038] B. Add a binder to the ingredients and adjust the water content to ≤13%, and then mix evenly;

[0039] C. Use a double-roller briquetting machine with a linear pressure of 3-8t / cm to form cold-pressed balls, and consolidate them into ellipsoidal green pellets with a size of 32×25×18mm;

[0040] D. Enter the through-flow mesh belt dryer, and the lower part is ventilated and dried to reduce the water content of the raw pellets to less than 2%;

[0041] E. Evenly distribute the dried green pellets on the rotary hearth furnace tray, the thickness of the cloth is about 2 layers; the rotary hearth furnace is divided into 4 areas, the temperature is 1150 ° C, 1200 ° C, 1250 ° C, 1300 ° C, the reduction time 15-30min, speed 25min / r; after reduc...

Embodiment 2

[0045] In this embodiment, the metallurgical dedusting ash used as carbon blending can be replaced by pulverized coal. At this time, the pulverized coal needs to be ground and filtered with a sieve mesh with a mesh size of not more than 100 mesh before being mixed with iron-containing dust.

[0046] In this embodiment, the dust collector in the flue gas system of the rotary hearth furnace can also be replaced by other forms of high temperature resistant dust collector.

[0047] In this embodiment, the cold consolidation method of material forming may also be disc pelletizing or extrusion forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com