Negative electrode material layer suitable for all-solid-state battery, preparation method of negative electrode material layer, negative plate and all-solid-state battery

A negative electrode material layer, all-solid-state battery technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as environmental pollution, potential safety hazards, and difficulty in reducing the amount of liquid electrolytes, and achieve improved safety performance, Avoidance of addition, effect of good ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

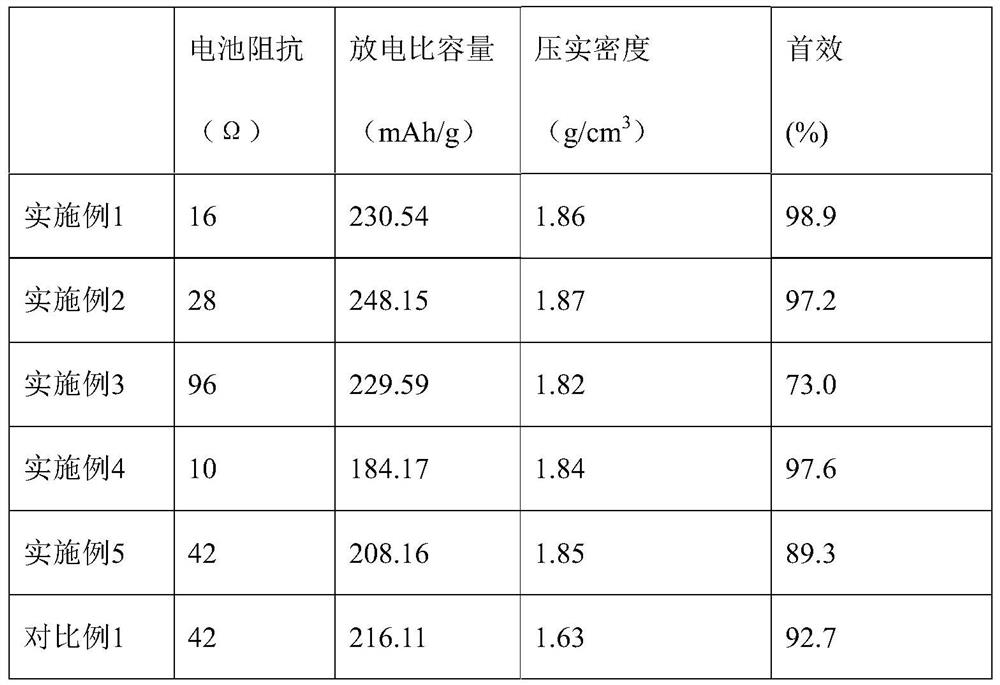

Examples

Embodiment 1

[0063] This embodiment provides a negative electrode material layer and a preparation method thereof, the method comprising the following steps:

[0064] 6.3g of graphite, 0.2g of carbon nanotubes, 3g of Li 6 P.S. 5 Add Cl into the mixer, stir at low speed (100rpm) for 10 minutes, mix well, then add 0.5g polytetrafluoroethylene, stir at low speed (100rpm) for 10 minutes, mix well, and stir at high speed (10000rpm) for 30 minutes, carry out the fibrosis process. Put the mixed powder into a roller press, perform hot rolling at 150°C to form a self-supporting film, and finally combine it with a current collector to obtain a negative electrode sheet.

[0065] The negative electrode material layer prepared in this example includes a network structure formed by overlapping polytetrafluoroethylene fibers, and graphite, a negative electrode active material, and a sulfide solid electrolyte Li dispersed and bonded in the network structure. 6 P.S. 5 Cl and conductive carbon nanotubes. ...

Embodiment 2

[0067] This embodiment provides a negative electrode material layer and a preparation method thereof, the method comprising the following steps:

[0068] 7g lithium nickel cobalt manganese oxide (Li(NiCoMn) 1 / 3 o 2 ), 0.2g carbon nanotubes, 2.3g Li 10 GeP 2 S 12 Add it into the mixer, stir at low speed (300rpm) for 10 minutes, mix well, then add 0.5g polytetrafluoroethylene, stir at low speed (300rpm) for 10 minutes, mix well, and stir at high speed (16000rpm) for 20 minutes, carry out fibrosis process. Put the mixed powder into a roller press, perform hot rolling at 150°C to form a self-supporting film, and finally combine it with a current collector to obtain a negative electrode sheet.

[0069] The negative electrode material layer prepared in this example includes a network structure formed by overlapping polytetrafluoroethylene fibers, and graphite, a negative electrode active material, and a sulfide solid electrolyte Li dispersed and bonded in the network structure....

Embodiment 3

[0071] The difference from Example 1 is that the mass proportion of the sulfide solid electrolyte is 8%, the mass proportion of the conductive agent is 2%, the binder mass proportion is 5%, the active material mass proportion is 85%, and other The preparation method and conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com