Soil stabilizer and preparation method thereof

A soil stabilizer and activator technology, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve problems such as restricting product promotion and application, increasing trouble and road construction costs, reducing the process of overturning, solving Emissions and environmental pollution issues, effects that are easy to add

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

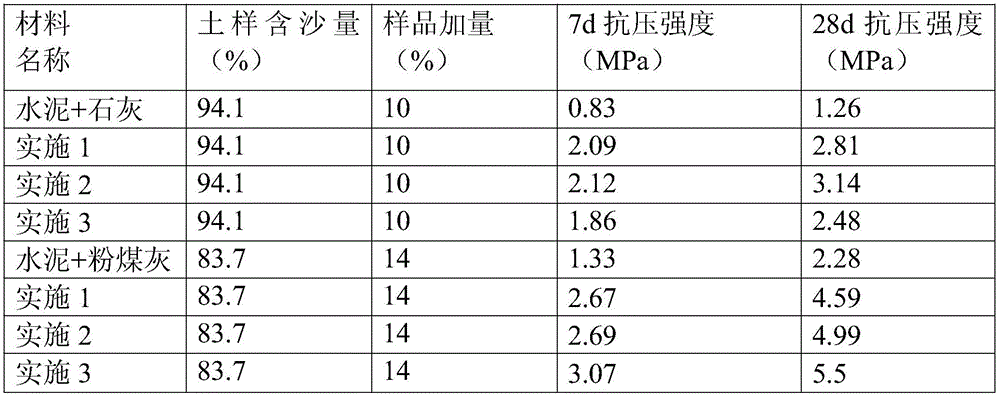

Embodiment 1

[0013] The soil curing agent, wherein, the weight percent of each component is: fly ash 50%, slag 9%, activator 7%, sodium sulfate 3.5%, triethanolamine 1%, polycarboxylic acid compound 0.5%, fat 0.5% family sulfonate, 28% cement clinker, 0.5% sodium fluorosilicate.

Embodiment 2

[0015] The soil curing agent, wherein, the weight percent of each component is: 40% of fly ash, 6% of slag, 7.5% of activator, 0.5% of triethanolamine, 40% of cement clinker, 1% of polycarboxylic acid compound, Sodium sulfate 3%, aliphatic sulfonate 1%, sodium fluorosilicate 1%.

Embodiment 3

[0017] Described soil solidifying agent, wherein, the percentage by weight of each component is: fly ash 32%, slag 5%, activator 5%, triethanolamine 1%, cement clinker 50%, polycarboxylate compound 2%, Sodium sulfate 2%, aliphatic sulfonate 1%, sodium fluorosilicate 2%.

[0018] The polycarboxylic acid compound is a polymer compound mainly composed of maleic acid-olefin, or a naphthalene-based polymer compound.

[0019] The aliphatic sulfonate and sodium fluorosilicate are existing public products, which can be purchased from Shandong Qingdao Century Xingyuan Technology Co., Ltd. and related chemical factories.

[0020] The curing principle of the soil curing agent of the present invention: after the soil curing agent is mixed with the soil, a series of physical and chemical reactions have produced a filling effect and a gelling effect on the consolidation of the soil, changing the engineering properties of the soil. In the reaction, the activator It can effectively stimulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com