Device and process method for preparing polycrystalline silicon through coupling of electron beam smelting and crystal growing technology

A technology of electron beam smelting and process method, which is applied in the direction of chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of increasing overall investment and low production efficiency, and achieve enhanced volatilization effect, improved production efficiency, saving investment and The effect of footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

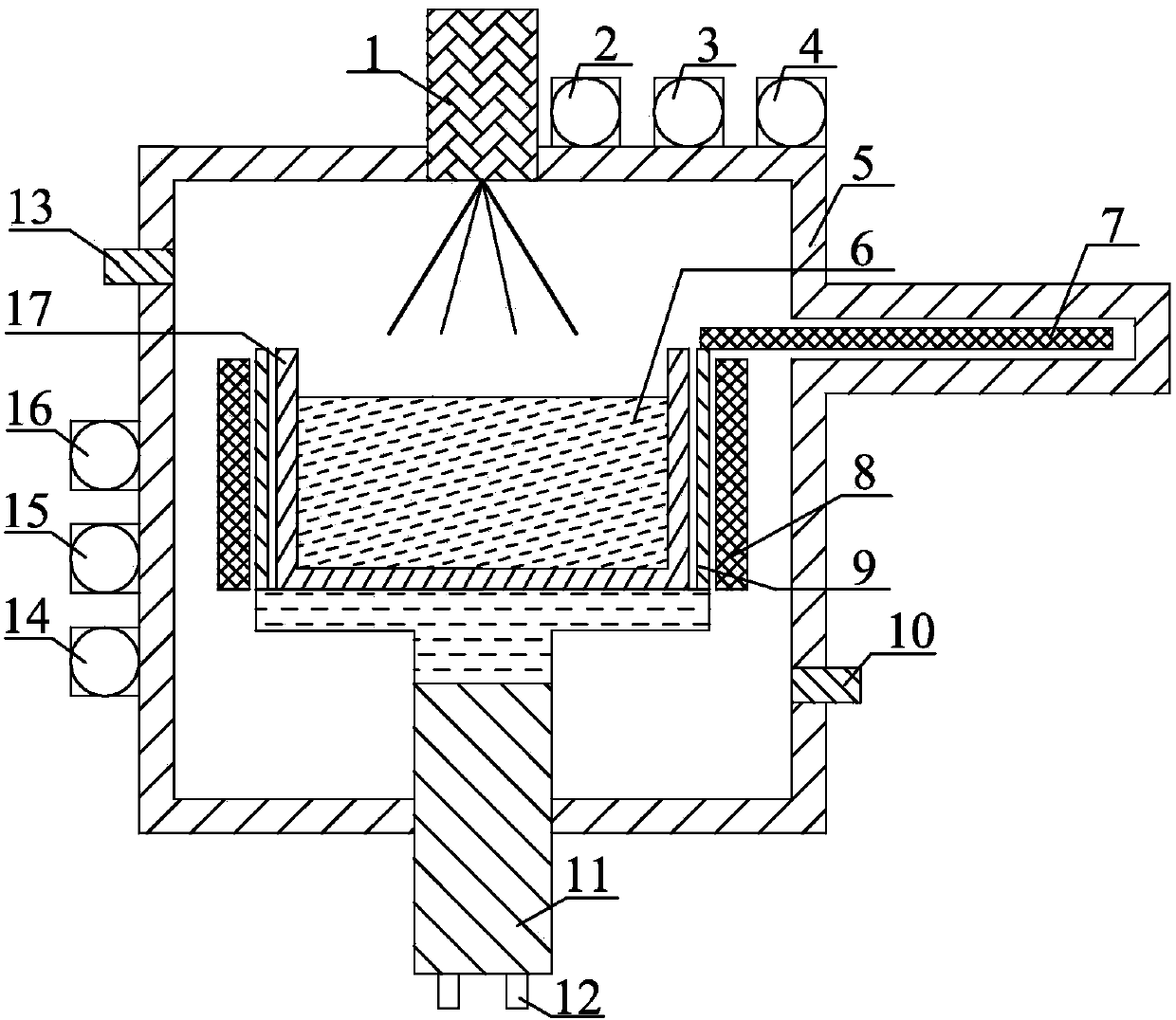

[0029] A graphite crucible 17 is placed inside the furnace body 5, and the inner surface of the graphite crucible 17 is coated with silicon carbide. The outer wall of the graphite crucible 17 is surrounded by a graphite heating body 9 and a graphite insulation cover 8 successively from the inside to the outside. The upper graphite cover plate 7 of the graphite insulation cover 8 can move horizontally, and is parallel to the upper graphite cover plate 7 on one side of the furnace body 5. There is a hollow plate groove outside the position; a water-cooled ingot pulling mechanism 11 is installed at the center of the bottom of the graphite crucible 5; a cooling circulating water pipe 12 is built in it; an electron gun 1 is connected to the top of the furnace body 5, and an inflatable valve 13 is opened on the upper end of the side. The lower end is provided with an air release valve 10.

Embodiment 2

[0031] Using the device in Example 1 to couple electron beam smelting and crystal growth technology to prepare polysilicon:

[0032] (1) Clean 500kg of polysilicon materials with a phosphorus content of 0.005%, a metal content of 0.00009%, and a boron content of 0.000014% with cleaning equipment to remove dust and oil stains on the surface, put them in a drying box, and dry them at 80°C Put the dried silicon material into the graphite crucible 17, move the graphite crucible 17 into the equipment for positioning; put the graphite crucible 17 into the graphite heating body 9, and the graphite heating body 9 is added with a graphite insulation sheath 8 to play Insulation effect.

[0033] (2) Put the equipment together, turn on the equipment cooling and circulating water device, and pass the cooling and circulating water to the equipment through the cooling and circulating water pipe 12; open the vacuum system of the furnace body, first use the mechanical pump 14 and the Roots pum...

Embodiment 3

[0040] Using the device in Example 1 to couple electron beam smelting and crystal growth technology to prepare polysilicon:

[0041] (1) Clean 500kg of polysilicon materials with a phosphorus content of 0.005%, a metal content of 0.00008%, and a boron content of 0.000013% with cleaning equipment to remove dust and oil stains on the surface, put them in a drying box, and dry them at 80°C dry; the dried silicon material is put into the graphite crucible 17, and the graphite crucible 17 is moved into the equipment for positioning; the graphite crucible 17 is put into the graphite heating body 9, and the graphite heating body 9 is added with a graphite insulation sheath 8, and the to the heat preservation effect.

[0042] (2) Put the equipment together, turn on the equipment cooling and circulating water device, and pass the cooling and circulating water to the equipment through the cooling and circulating water pipe 12; open the vacuum system of the furnace body, first use the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com