Battery-grade cobaltosic oxide preparation method

A technology of tricobalt tetroxide and battery level, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., which can solve the problems of complex process, uneven particle size range of powder, large battery volume, etc., and achieve optimized preparation process, narrow particle size distribution and chemical purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

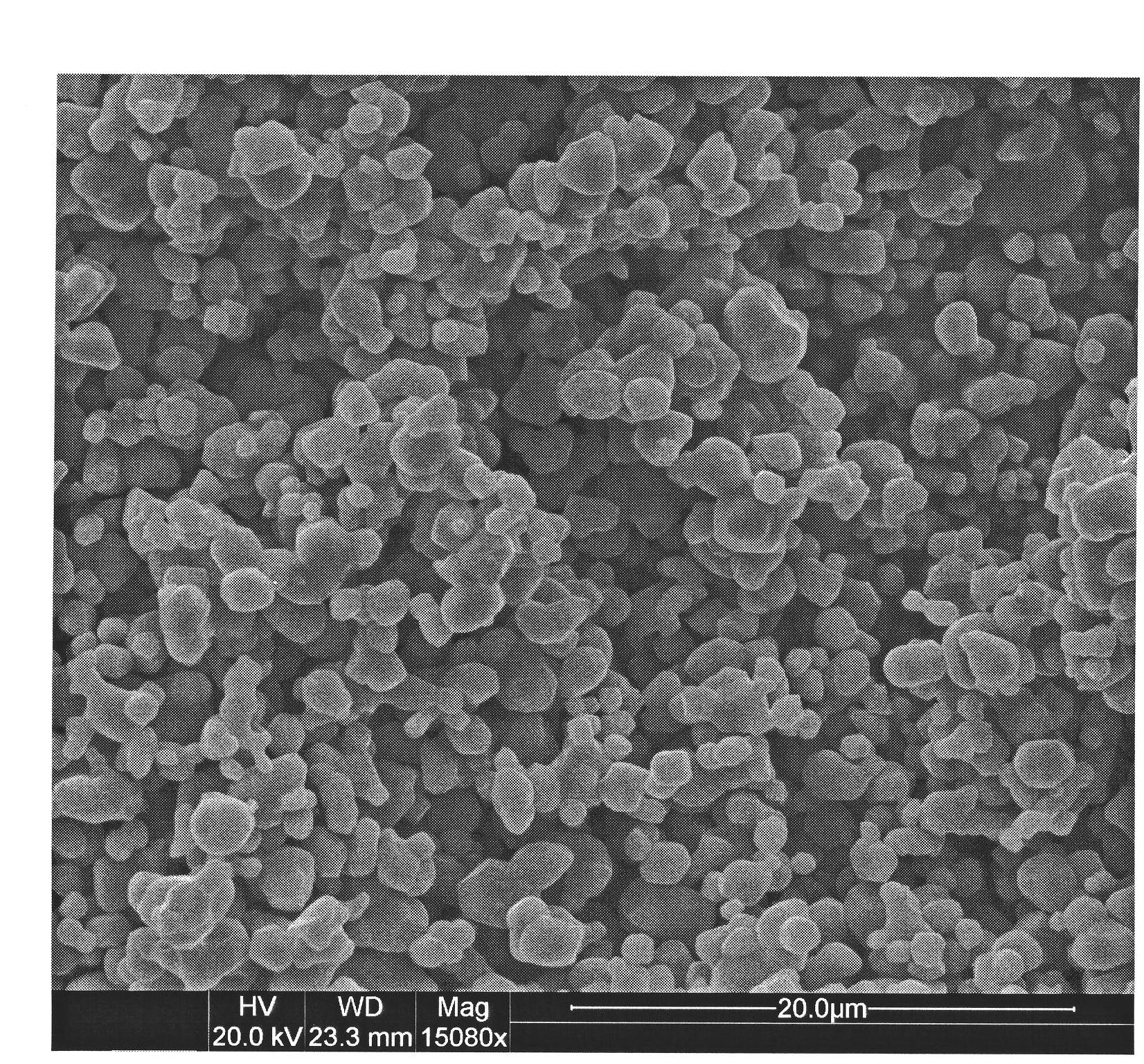

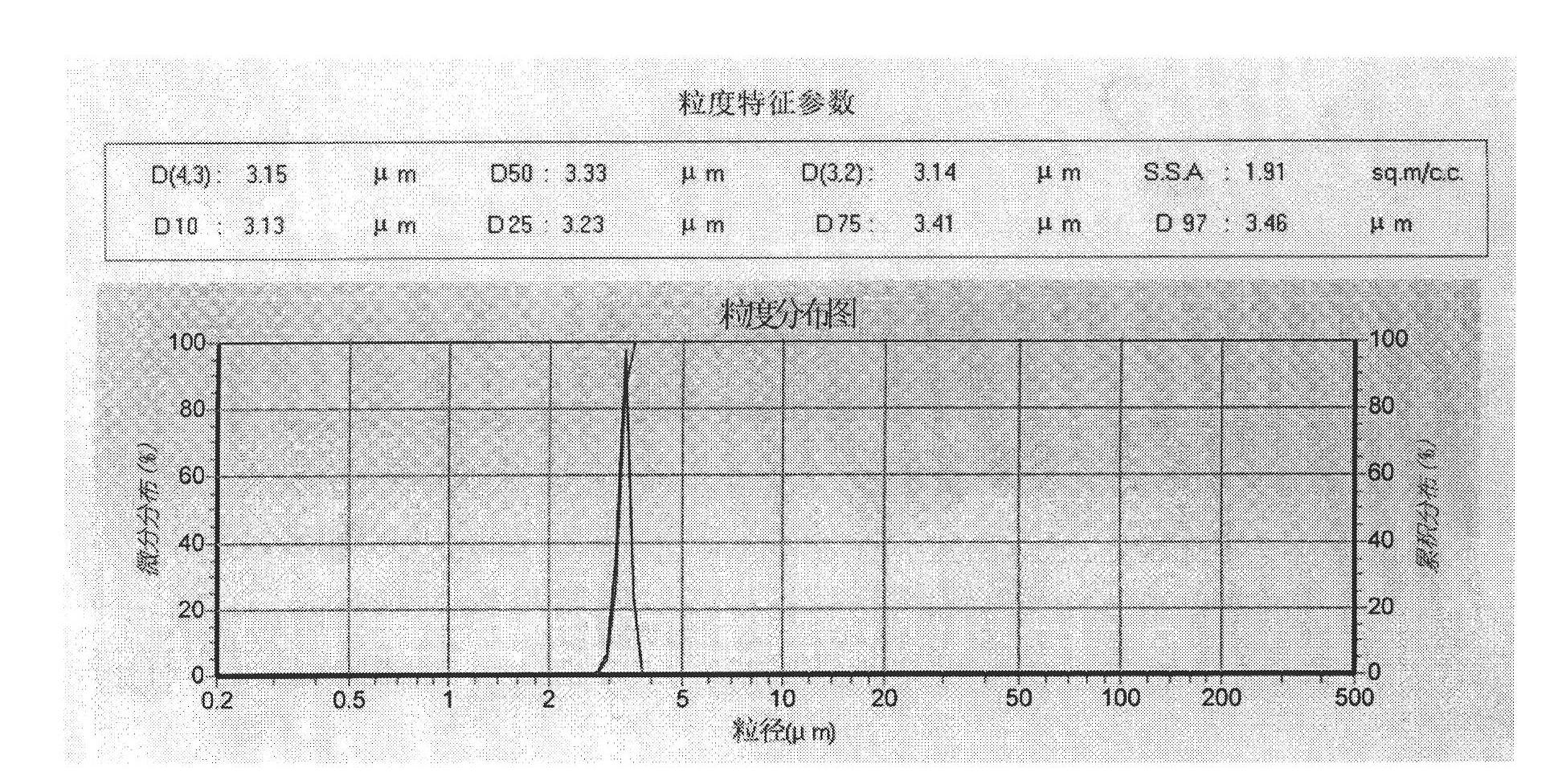

Embodiment 1

[0040] Use deionized water to make industrial-grade cobalt sulfate into a solution with a cobalt concentration of 60g / L, use deionized water to make ammonium bicarbonate into a precipitant solution with a concentration of 100g / L, and massage the cobalt solution and the precipitant solution Il ratio, cobalt: precipitating agent=1.0: 2.1, add reaction container with co-current feeding method, the adding speed of described cobalt solution and the adding speed of described precipitating agent solution are determined according to container size, control the reaction that precursor is synthesized The temperature is 60°C, the reaction pH value is 7.0, the stirring speed is 300rpm, and the reaction time is . The precursor is prepared by the homogeneous crystallization precipitation method. The precursor is washed with 80°C deionized water for 3 times and then dehydrated. The water content of the filter cake is 25%, put it directly into a bowl, put it into a roasting furnace and bake it...

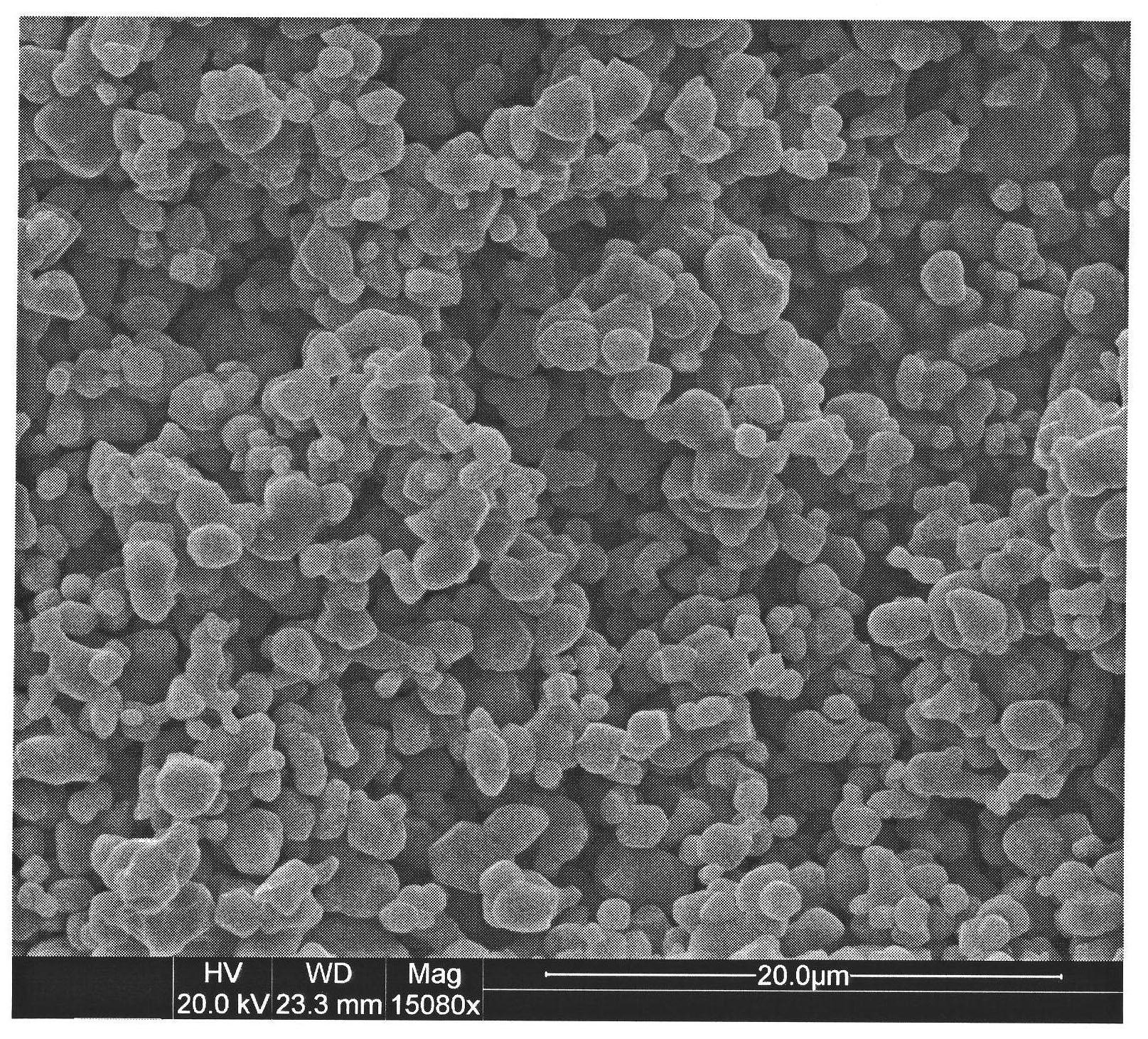

Embodiment 2

[0042] With deionized water, industrial-grade cobalt nitrate is prepared into a solution with a cobalt concentration of 80g / L, and with deionized water, ammonium carbonate is made into a precipitant solution with a concentration of 80g / L, and the cobalt solution and the precipitant solution are molarally Ratio, cobalt: precipitating agent=1.0: 3.0, add reaction container with co-current feeding method, control the reaction temperature of precursor synthesis to be 80 ℃, reaction pH value is 8.5, stirring speed is 500rpm, and reaction time is 15 hours, with average The precursor was prepared by phase crystallization and precipitation method. The precursor was washed with deionized water at 90°C for 5 times and then dehydrated. The water content of the filter cake was 24%. , naturally cooled to below 400°C and released from the furnace, lowered to room temperature, after crushing and grading, metal foreign matter was removed by iron remover to obtain spherical cobalt trioxide powd...

Embodiment 3

[0044] Use deionized water to make industrial-grade cobalt chloride into a solution with a cobalt concentration of 70g / L, use deionized water to make sodium carbonate into a precipitant solution with a concentration of 100g / L, and massage the cobalt solution and the precipitant solution Il ratio, cobalt: precipitating agent=1.0: 3.8, add reaction vessel with co-current feeding method, control the reaction temperature of precursor synthesis to be 100 ℃, the reaction pH value is 9.0, stirring speed is 500rpm, and the reaction time is 8 hours, with The precursor was prepared by homogeneous crystallization precipitation method. The precursor was washed with deionized water at 100°C for 5 times and then dehydrated. The water content of the filter cake was 24%. Hours, naturally cooled to below 400°C and released from the furnace, lowered to room temperature, after crushing and grading, metal foreign matter was removed by iron remover to obtain spherical cobalt trioxide powder, D 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com