Benefication of magnetite-haematite acid mixed mine

A technology for hematite and mixed ore, applied in chemical instruments and methods, magnetic separation, wet separation, etc., can solve problems such as equipment environmental pollution, gangue recovery, waste of iron resources, etc., to improve economic benefits and rational use The effect of high resource and concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Selected ore chemical composition: SiO 2 18.32%, TFe 50.63%, S 0.013%, P 0.061%, K 2 O 0.082%, Na 2 O 1.095%.

[0018] A. Grind the raw ore with water so that the grinding fineness reaches -200 mesh, accounting for 50%, control the pulp concentration to 50%, carry out a section of strong magnetic separation under the condition of a magnetic field strength of 6000 austeres, discard the tailings, and obtain a grade of 30 % coarse concentrate;

[0019] B. Continue to grind the above-mentioned coarse concentrate so that the fineness reaches -200 mesh, accounting for 70%, control the pulp concentration to 30%, and carry out the second-stage strong magnetic separation under the condition of a magnetic field strength of 5000 austeres, and the selected grade reaches 40 % concentrate pulp;

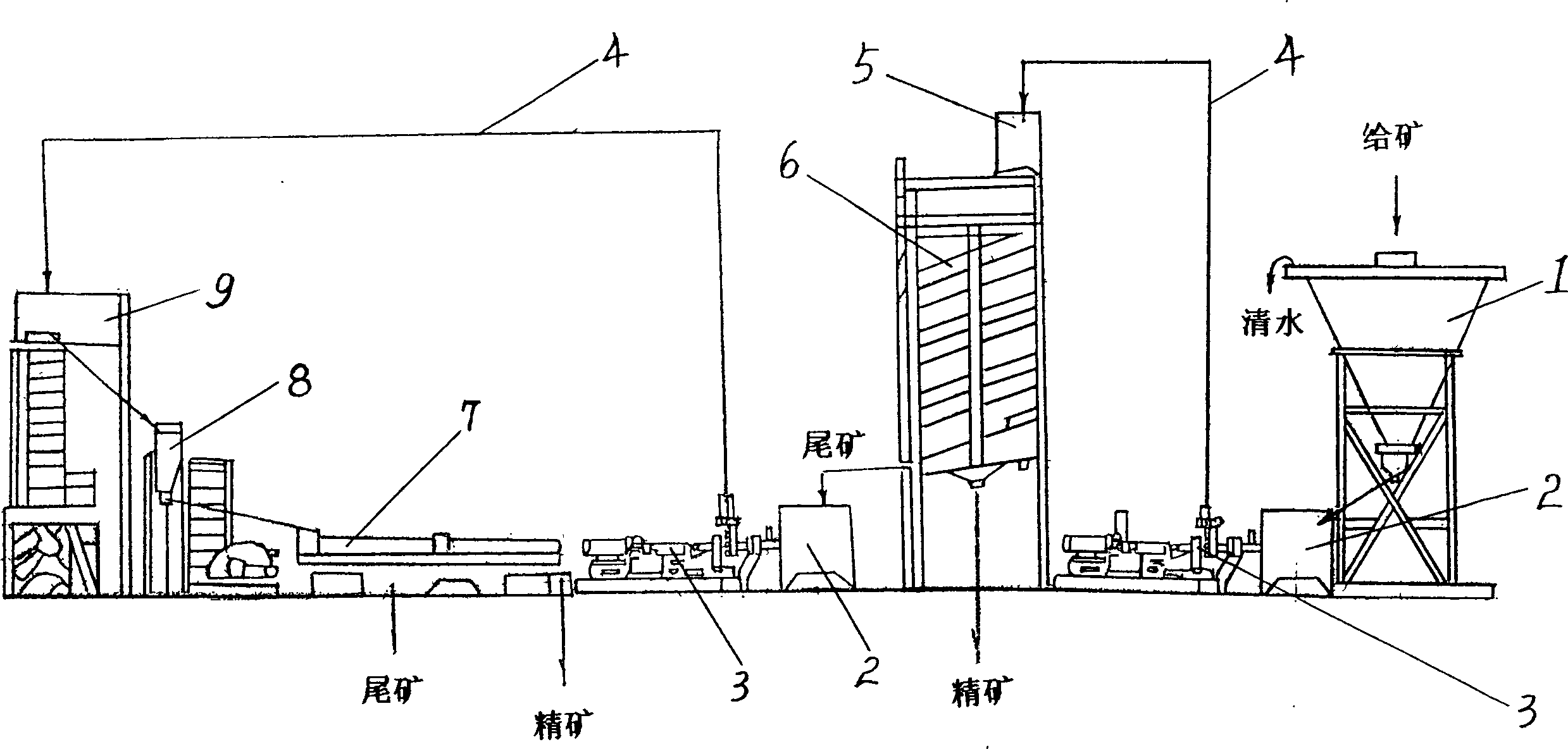

[0020] C. Flow the above-mentioned concentrated ore slurry into the mud separator 1 by gravity, concentrate and keep the overflow of the mud separator as clear water, and keep the conce...

Embodiment 2

[0026] A. Grind the raw ore with water to make the grinding fineness reach -200 mesh, accounting for 60%, control the pulp concentration to 80%, carry out a stage of strong magnetic separation under the condition of a magnetic field strength of 8000 austeres, discard the tailings, and obtain a grade of 47 % coarse concentrate;

[0027] B. Continue to grind the above-mentioned coarse concentrate so that its fineness reaches -200 mesh, accounting for 85%, control the pulp concentration to 40%, and carry out two-stage strong magnetic separation under the condition of a magnetic field strength of 6000 austeres, and the selected grade reaches 47 % concentrate pulp;

[0028] C. Flow the above-mentioned concentrated ore slurry into the mud separator 1 by gravity, concentrate and keep the overflow of the mud separator as clear water, and keep the concentration of the bottom flow pulp at 30%;

[0029] D. Send the above-mentioned ore slurry to the distribution box 5 of the spiral chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com