Operation control method of high magnetic grading process

A technology of operation control and strong magnetic separation, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as inability to guarantee product quality, unfavorable system maintenance, and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

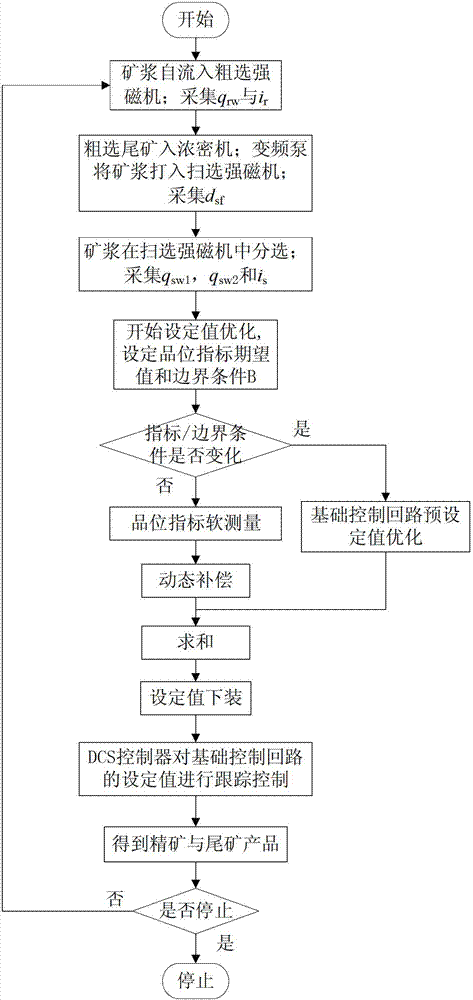

[0079] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

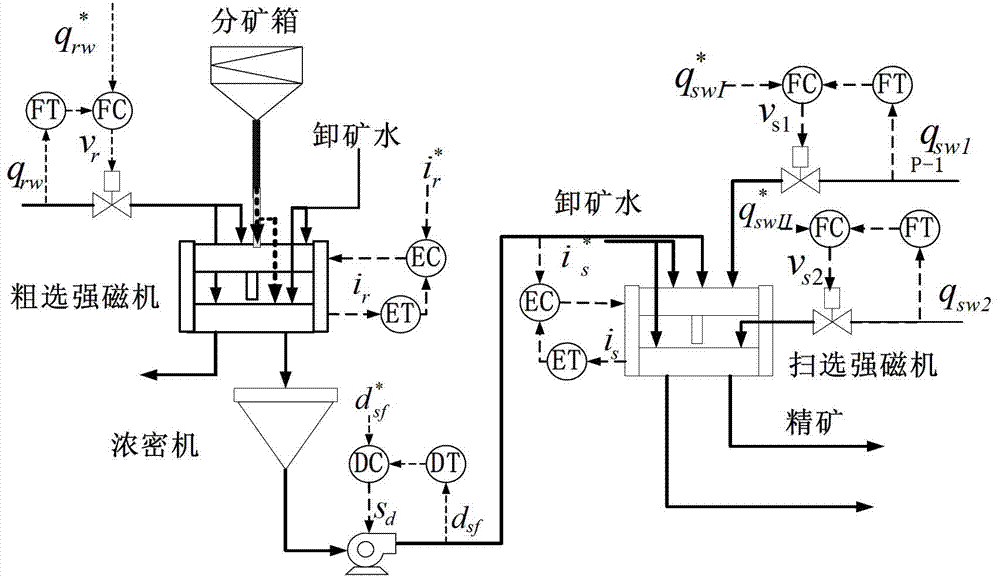

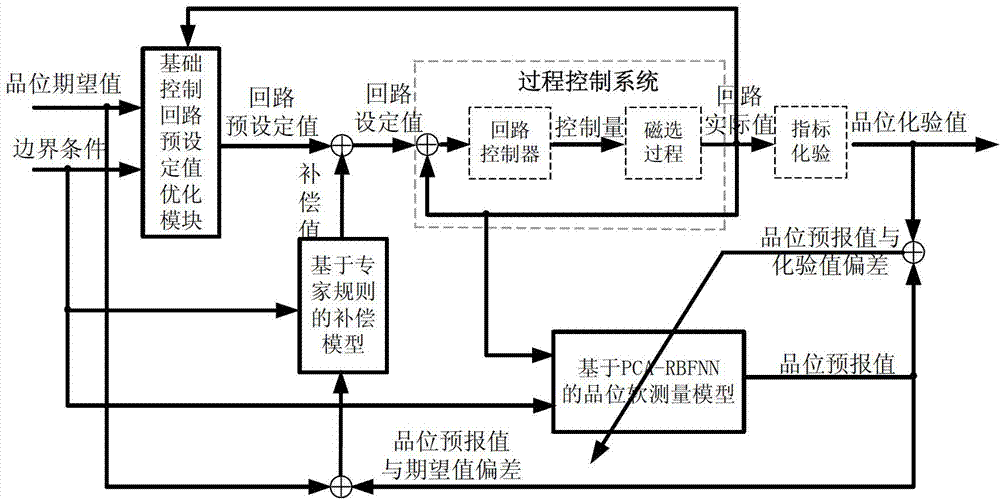

[0080] The embodiment of the present invention is a strong magnetic beneficiation of a large-scale iron ore dressing plant. The main iron ores of the ore dressing plant are pyrite and limonite, and the gangue is mainly barite, quartz, jasper and iron dolomite. , The actual iron grade of the ore is 33%. The process flow of strong magnetic separation process is as follows: figure 1 As shown, the overflow ore pulp from the grinding operation enters the ore separation box and then flows into the separation area of the roughing strong magnetic machine. The ore particles with weaker magnetism are directly washed away by the ore washing rinse water and become tailings. The ore particles are washed down by the unloading water to become concentrate. The rough selected concentrate enters the concentrate well, and the tailings enter the thickene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com