Method for recovering waste battery lithium foil

A waste battery and recovery method technology, applied in the field of lithium foil recovery, can solve the problems of large surface area, low recovery rate, and poor product quality, and achieve the effects of high metal recovery rate, safe recovery method, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

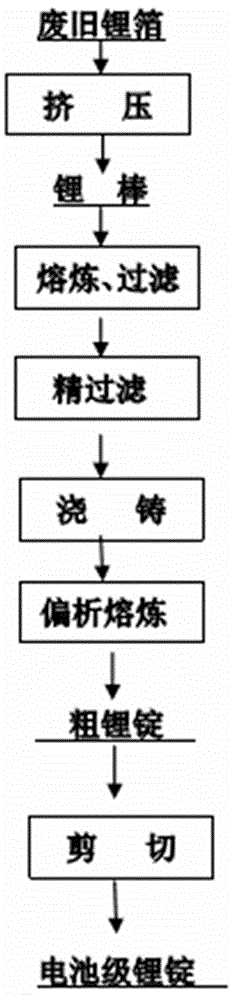

Image

Examples

Embodiment

[0040] 1) In a drying room with a relative humidity of ≤2%, use a ¢350×400mm extruder with an extrusion force of 50 tons to extrude the bubbly waste lithium foil into a ¢120×1000mm lithium rod.

[0041] 2) Weigh 50Kg¢120×1000mm lithium rod, and add the lithium rod into the molten lithium tank under the protection of argon. Vacuum smelting and filtering are carried out in the lithium melting furnace to remove impurities and most of them. Melting vacuum: ≤1Pa, temperature: 200-220°C, time: 2 hours, filtration accuracy ≤50 microns.

[0042] 3) After the smelting operation is completed, the material in the lithium melting tank is filtered through a pipeline metal filter into a pure lithium tank to remove fine impurities such as lithium oxide and lithium nitride. Temperature: 200-220°C, filtration accuracy ≤2 microns.

[0043] 4) In a fully enclosed casting machine filled with argon, the materials obtained in step 3) are sequentially cast into metal molds of ¢125×300mm.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com