Resource recovery processing method of waste circuit board

A waste circuit board, resource recycling technology, applied in the direction of electronic waste recycling, recycling technology, solid waste removal, etc., can solve the problems of not realizing effective recycling, achieve continuous industrial processing, avoid dioxin generation, reduce The effect of generation of harmful gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

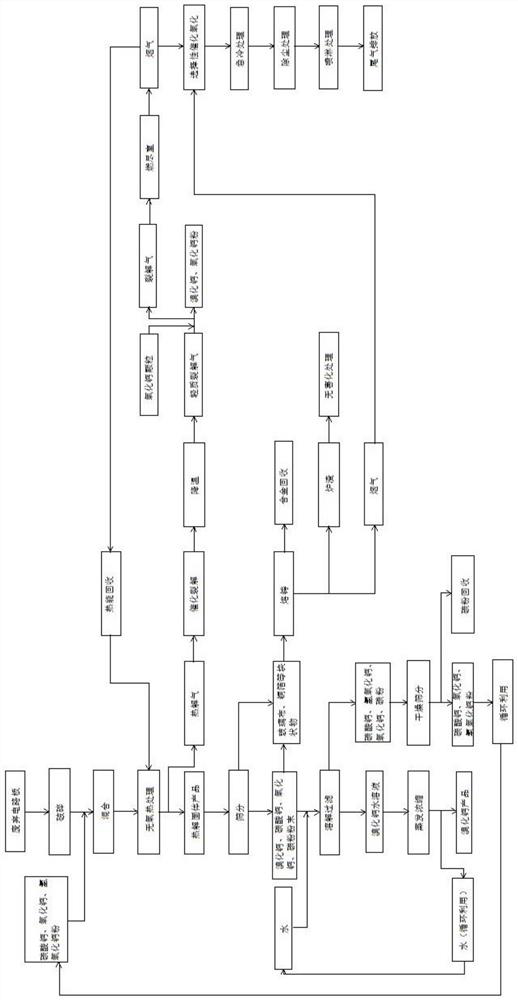

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, on the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0034] like figure 1 A resource recovery processing method for waste circuit boards shown includes the following steps:

[0035] (1) Crushing the entire waste circuit board into small pieces with a diameter of 0.5 to 1mm through a crusher;

[0036] (2) The fragmented circuit board obtained in step (1) is mixed together with additives by a mixer, and the additives include calcium carbonate and calcium oxide, wherein the mass ratio of the additive to the circuit board is 1.3;

[0037] (3) Add the mixture of step (2) into the pyrolysis furnace, and perform anaerobic pyrolysis treatment at a temperature of 600° C. to obtain pyrolysis solid products and pyro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com