Magnetism-gravity combined separation technology for magnetic hematite mixed type rough concentrate

A mixed-type, coarse-concentrate technology, applied in the directions of magnetic separation, solid separation, screening, etc., can solve the problems of high tailings grade, low recovery rate of fine-grained hematite, multi-selection cost, etc., to achieve High concentrate grade and metal recovery rate, easy to achieve stable operation, and avoid the effect of high concentrate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

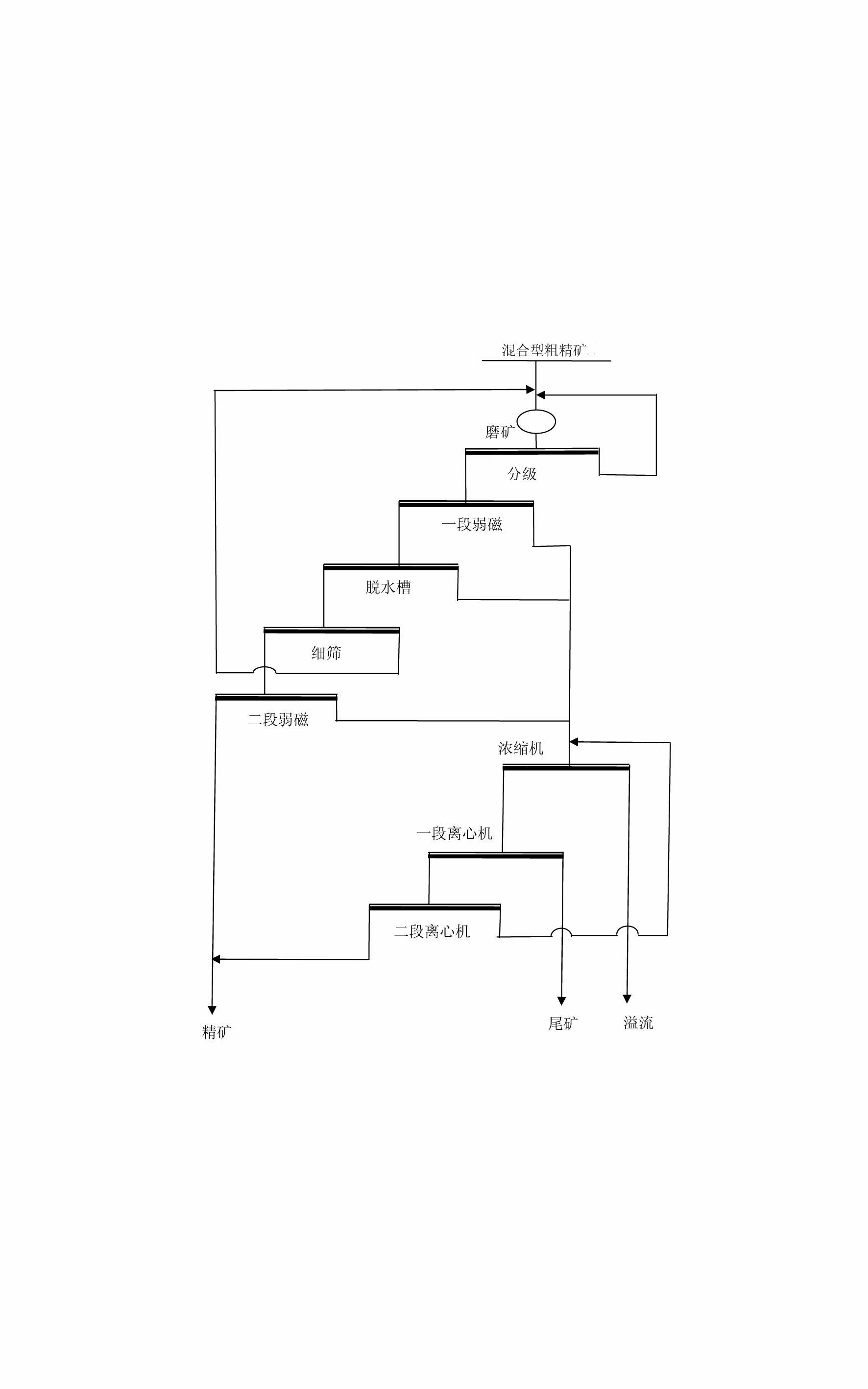

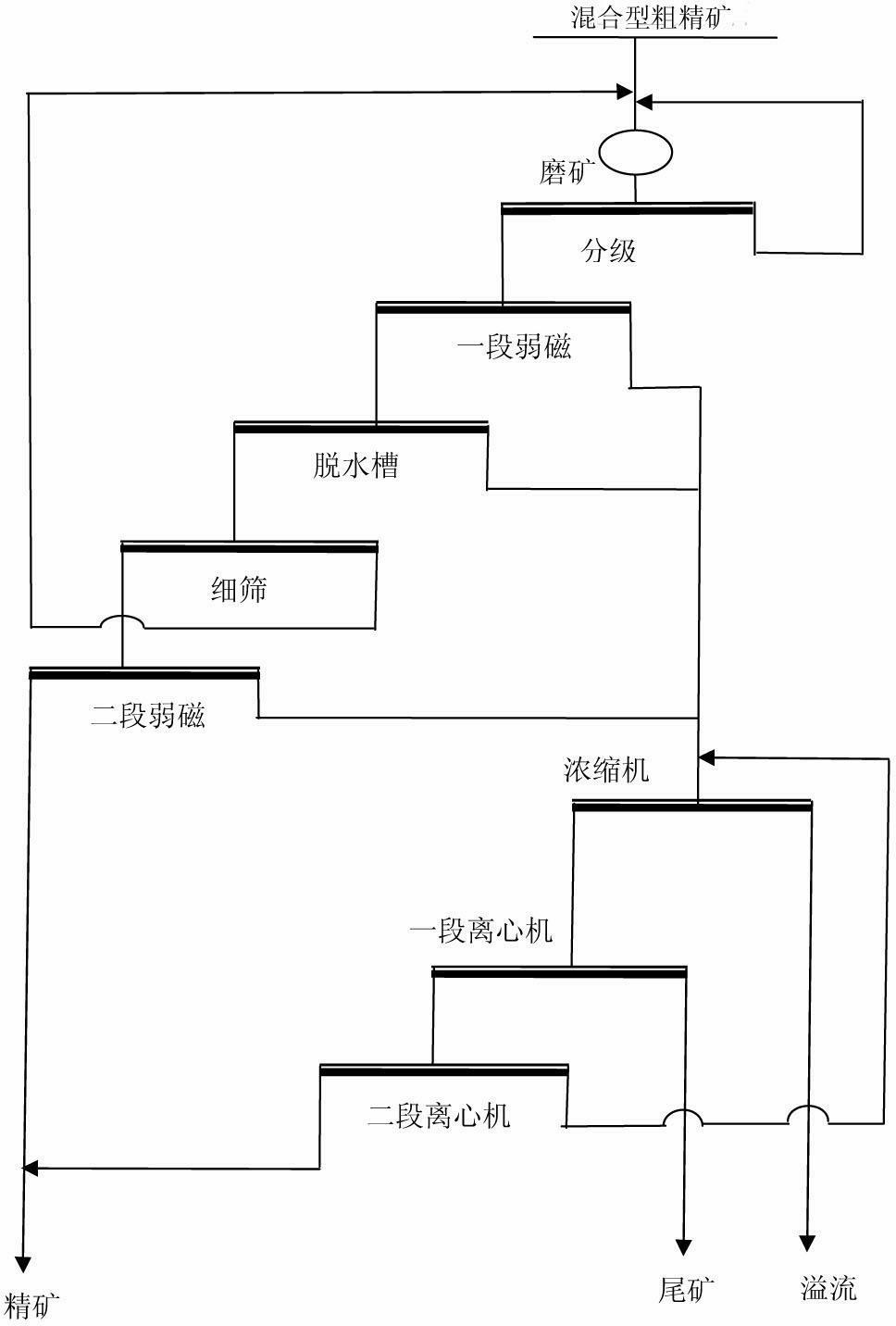

Method used

Image

Examples

Embodiment 1

[0066] 1) The magnetic and red mixed type coarse concentrate with a particle size of -200 mesh, a content of 65.2%, and a grade of 51.2% is fed into a closed-circuit grinding system consisting of grinding and grading.

[0067] 2) Grain size -200 mesh content 94.24%, weight concentration 35.0% grinding and grading overflow is fed into a section of weak magnetic field, the magnetic field strength of a section of weak magnetic separator is 2150 Oe, and the concentrate grade of a section of weak magnetic field is 59.87%. The grade of tailings with weak magnetic field is 49.35%,

[0068] 3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 950 Oe. Mesh sieve with a mesh size of 0.09×0.09mm,

[0069] 4) The coarse-grained products on the sieve are returned to the ore grinding, and the fine-grained products under the sieve are fed into the second-stage weak magnetic separator. The magnetic field strength o...

Embodiment 2

[0076] 1) The magnetic and red mixed type coarse concentrate with a particle size of -200 mesh, a content of 67.51%, and a grade of 54.49% is fed into a closed-circuit grinding system consisting of grinding and grading.

[0077] 2) Grain size -200 mesh content 93.74%, weight concentration 33.5% grinding and grading overflow is fed into a section of weak magnetic separator, the magnetic field strength of a section of weak magnetic separator is 2100 Oe, and the concentrate grade of a section of weak magnetic field is 60.60%. The grade of tailings with weak magnetic field is 49.57%,

[0078] 3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 900 Oe. Mesh sieve with a mesh size of 0.09×0.09mm,

[0079] 4) The coarse-grained products on the sieve are returned to the ore grinding, and the fine-grained products under the sieve are fed into the second-stage weak magnetic separator. The magnetic field stre...

Embodiment 3

[0086] 1) The magnetic and red mixed type coarse concentrate with a particle size of -200 mesh, a content of 72.0%, and a grade of 57.30% is fed into a closed-circuit grinding system consisting of grinding and grading.

[0087] 2) Grain size -200 mesh content 93.50%, weight concentration 35.5% of the grinding and grading overflow is fed into a section of weak magnetic separator, the magnetic field strength of the first section of weak magnetic separator is 2000 Oe, the concentrate grade of the first section of weak magnetic field is 60.88%, and the first section of weak magnetic separator is 60.88%. The grade of tailings with weak magnetic field is 49.64%,

[0088] 3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 850 Oe. Mesh sieve with a mesh size of 0.08×0.08mm,

[0089] 4) The coarse-grained products on the sieve are returned to the ore grinding, and the fine-grained products under the sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com