Beneficiation method and device for quartz vein type gold deposit

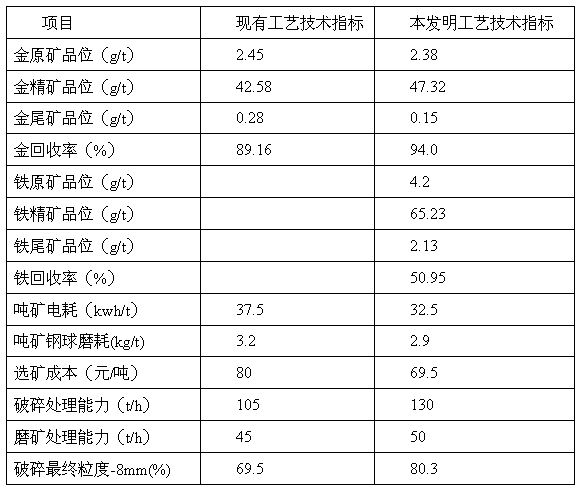

A mineral processing method and gold ore technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as difficult to achieve more crushing and less grinding, failure to achieve monomer dissociation, high grinding cost, and achieve The effects of reduced steel ball wear, reduced power consumption, and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

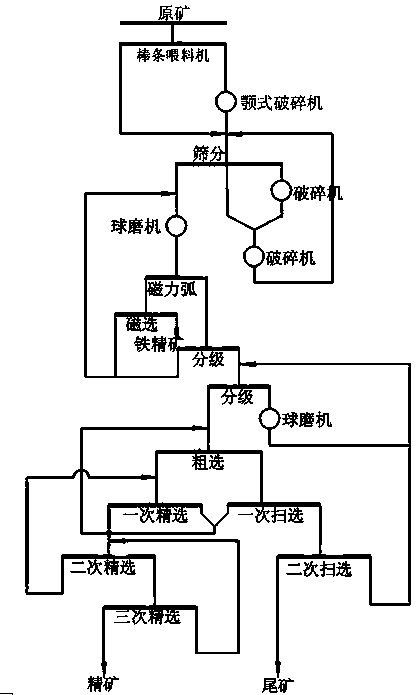

[0024] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

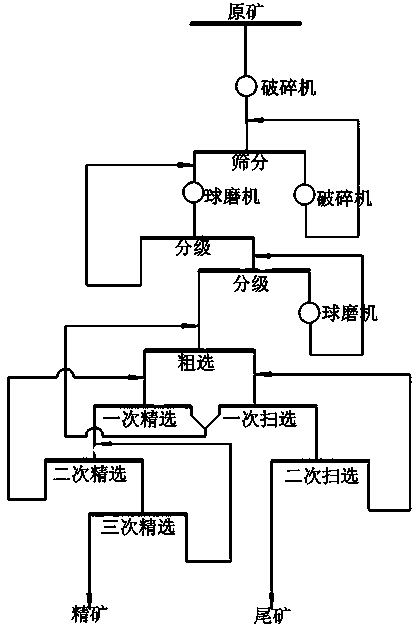

[0025] The beneficiation process flow of prior art quartz vein type gold mine is as follows figure 1 As shown, the raw ore enters the raw ore bin through the 600*600mm grid screen, and the grid screen is equipped with a fixed breaker. The large pieces larger than 600mm are broken by the fixed breaker, and the material on the screen is fed into the jaw crusher through the bar feeder. First-stage crushing, the crushing particle size is less than 80mm, the first-stage crushing product and the second-stage crushing product are combined and sent to the double-layer circular vibrating screen with a screen hole of 10mm for screening through the belt conveyor, and the upper product is sent to the cone through the electric vibrating feeder. The crusher performs secondary crushing. After being weighed by the electronic belt conveyor, the screened produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com