Recleaning process for section of strong magnetic tailings in mixed lean iron ores

A technology of lean iron ore and mixed type is applied in the field of high-magnetic tailings re-selection process of the first stage of mixed lean iron ore, which can solve the problems of difficulty in reducing the grade and the inability to effectively improve the resource utilization rate, etc., and achieves high production efficiency and improved Resource utilization rate and enterprise economic benefit, effect of low tailings grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

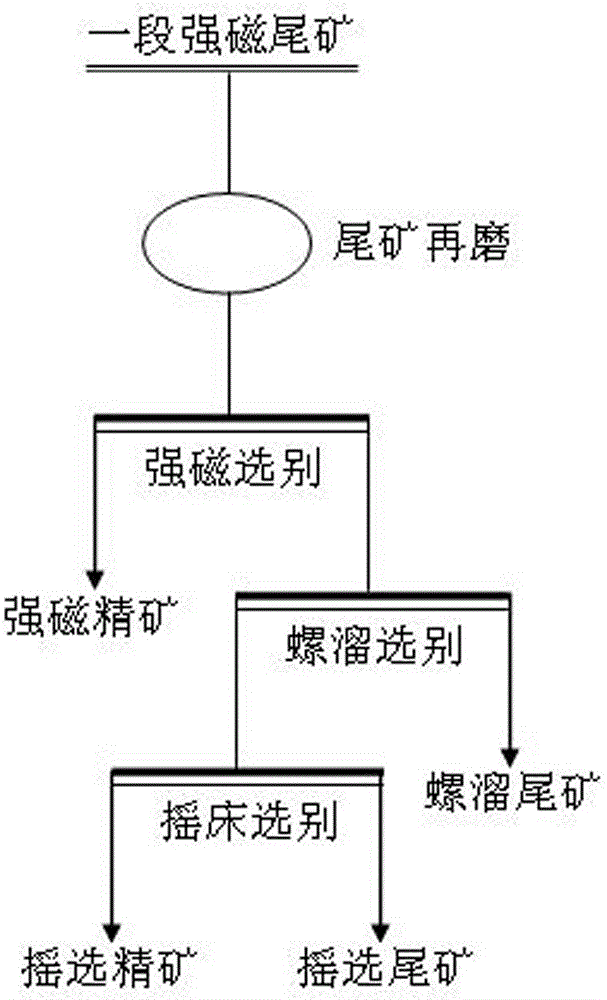

Method used

Image

Examples

Embodiment 1

[0026] Add water to grind the tailings with a grade of 23% after strong magnetic separation in the Dahongshan Concentrator of Kunming Iron and Steel Co., Ltd. to a fineness of -0.045mm, accounting for 95% by weight of the regrind pulp, and control the concentration of the pulp to 65%; The grinding pulp is deslimed by adding water to the separation box to obtain bottom ore and overflow tailings with a pulp concentration of 35%, and the bottom ore is sent to a superconducting magnetic separator with a magnetic field strength of 20,000 Oersted to obtain strong magnetic concentrate and magnetic separation tailings ; The magnetic separation tailings are sorted through a vibrating spiral chute to obtain a snail concentrate and a snail tailing with a concentration of 25%; Concentrate and shaking tailings. The shaker sorting is carried out in stages, and a single rough selection is performed once.

Embodiment 2

[0028] Add water to grind the tailings with a grade of 23% after strong magnetic separation in the Dahongshan Concentrator of Kunming Iron and Steel Co., Ltd. to a fineness of -0.045mm, accounting for 95% by weight of the regrind pulp, and control the concentration of the pulp to 65%; The grinding pulp is deslimed by adding water to the separation box to obtain bottom ore and overflow tailings with a pulp concentration of 35%, and the bottom ore is sent to a superconducting strong magnetic machine with a magnetic field strength of 20,000 Oersted to obtain strong magnetic concentrate and magnetic separation tailings ; The magnetic separation tailings are sorted through a vibrating spiral chute to obtain a snail concentrate and a snail tailing with a concentration of 25%; Concentrate and shaking tailings. The shaking table sorting is not carried out in different grades, one time for rough selection and two times for fine selection.

Embodiment 3

[0030] Add water to grind the tailings with a grade of 20% after strong magnetic separation in the Dahongshan Concentrator of Kunming Iron and Steel Co., Ltd. to a fineness of -0.045mm and account for 80% by weight of the regrind pulp, and control the concentration of the pulp to 70%; Weak magnetic concentrate and weak magnetic tailings are obtained by grinding slurry through weak magnetic separation with a magnetic field strength of 1000 Oersted; the weak magnetic tailings are deslimed through the ore separation box to obtain bottom ore and overflow tailings with a pulp concentration of 30% , the bottom ore is sent into the Jones wet strong magnetic field magnetic separator with a magnetic field strength of 7000 Oersted to obtain rough concentrate and magnetic separation tailings, and the rough concentrate is a high gradient magnetic separator with a magnetic field strength of 15000 Oersted Concentrate to obtain strong magnetic concentrate and magnetic separation tailings; sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com