A kind of natural crystalline flake graphite fine powder processing method for preparing high-purity graphite

A flake graphite and high-purity graphite technology, which is applied in the field of natural crystalline flake graphite fine powder treatment, can solve the problems of bad chlorine environment, poor process stability, and limited purification effect, and achieve multiple contact areas and contact probability, and increase the reaction The contact area and the effect of shortening the time for removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

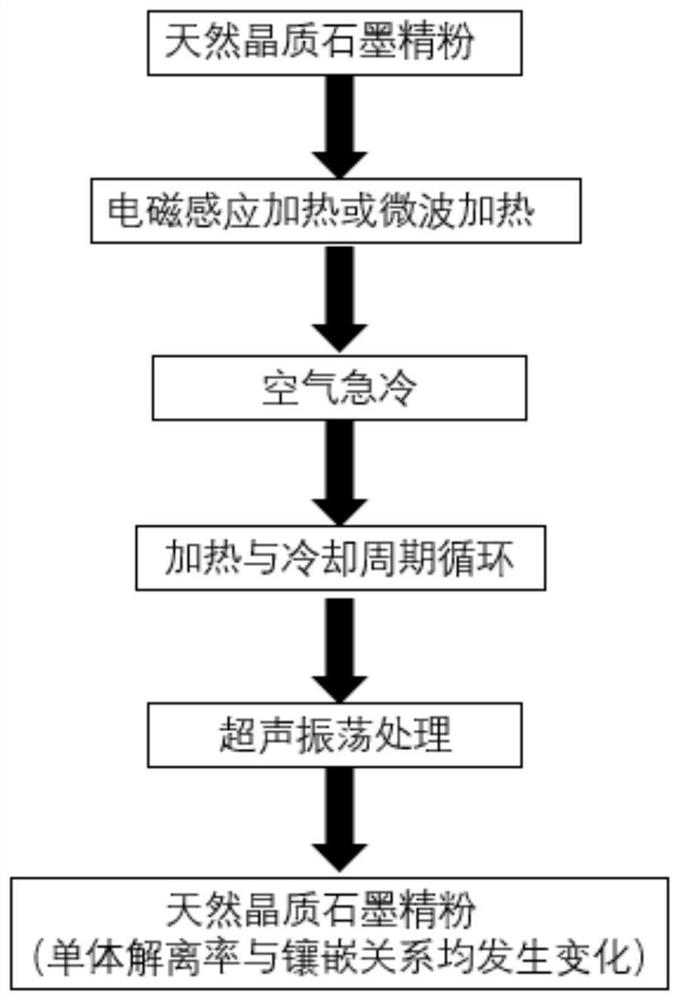

[0033] Such as figure 1 Shown, a kind of natural crystalline flake graphite fine powder processing method that the present invention is used to prepare high-purity graphite specifically comprises the following steps:

[0034] 1) Under normal temperature and pressure, heat the graphite fine powder to 400°C-450°C, and then air quench to 0°C-5°C;

[0035] 2) Repeat step 1) for 5-20 times;

[0036] 3) After each heating and cooling cycle, the fine graphite powder is subjected to ultrasonic vibration treatment, the frequency of ultrasonic vibration treatment is 300MHZ-300GHZ, and the ultrasonic vibration treatment time is 30min-45min.

[0037] Wherein, in step (1), the heating of graphite adopts electromagnetic induction heating or microwave vibration heating. The electromagnetic induction heating method is high-frequency heating; the working frequency of microwave heating is 300MHZ~300GHZ.

[0038] It takes 10min to 15min for the temperature of graphite fine powder to drop from...

Embodiment 2

[0040] The present invention is a kind of processing method for the natural crystalline flake graphite fine powder that is used for preparing high-purity graphite, specifically comprises the following steps:

[0041] 1) Under normal temperature and pressure, heat the graphite fine powder to 450°C, and then air-cool it rapidly to 0°C;

[0042] 2) Repeat the operation of step 1) 10 times;

[0043] 3) After each heating and cooling cycle, the fine graphite powder is subjected to ultrasonic vibration treatment, the frequency of ultrasonic vibration treatment is 10GHZ, and the ultrasonic vibration treatment time is 30min1.

[0044] Wherein, in step (1), the heating of graphite adopts electromagnetic induction heating or microwave vibration heating. The electromagnetic induction heating method is high-frequency heating; the working frequency of microwave heating is 10GHZ.

[0045] It takes 10 minutes for the temperature of graphite fine powder to drop from 450°C to 0°C.

Embodiment 3

[0047] The present invention is a kind of processing method for the natural crystalline flake graphite fine powder that is used for preparing high-purity graphite, specifically comprises the following steps:

[0048] 1) Under the protection of inert gas, heat the graphite fine powder to 700°C, and then quench the inert gas to 2°C;

[0049] 2) Repeat the operation of step 1) 6 times;

[0050] 3) After each heating and cooling cycle, the fine graphite powder is subjected to ultrasonic vibration treatment, the frequency of ultrasonic vibration treatment is 10GHZ, and the ultrasonic vibration treatment time is 30min.

[0051] Wherein, in step (1), the heating of graphite adopts electromagnetic induction heating or microwave vibration heating. The electromagnetic induction heating method is high-frequency heating; the working frequency of microwave heating is 10GHZ.

[0052] It takes 10 minutes for the temperature of graphite fine powder to drop from 700°C to 2°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com