Method for increasing yield of reverse flotation iron concentrate and reducing consumption of caustic soda

A technology for iron concentrate and reverse flotation, which is applied in chemical instruments and methods, wet separation, solid separation, etc. The effect of mineral filtration efficiency, elimination of carbonation, and improvement of monomer dissociation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

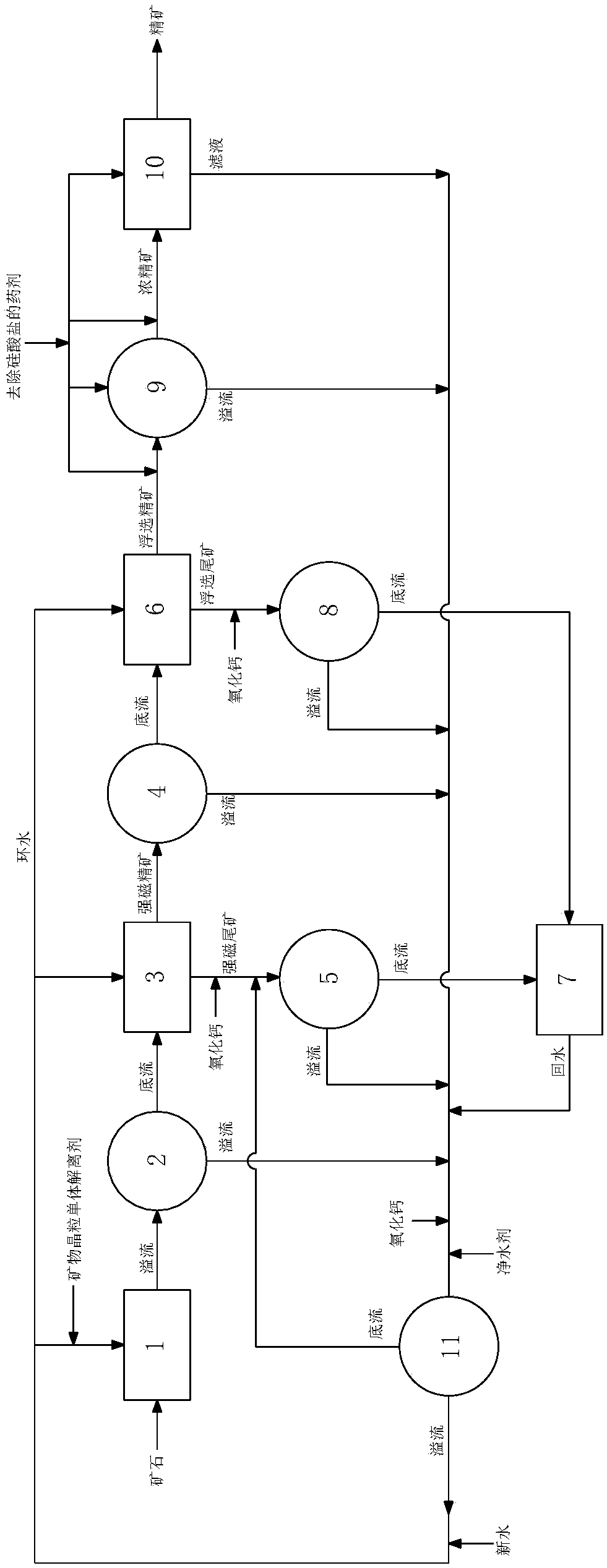

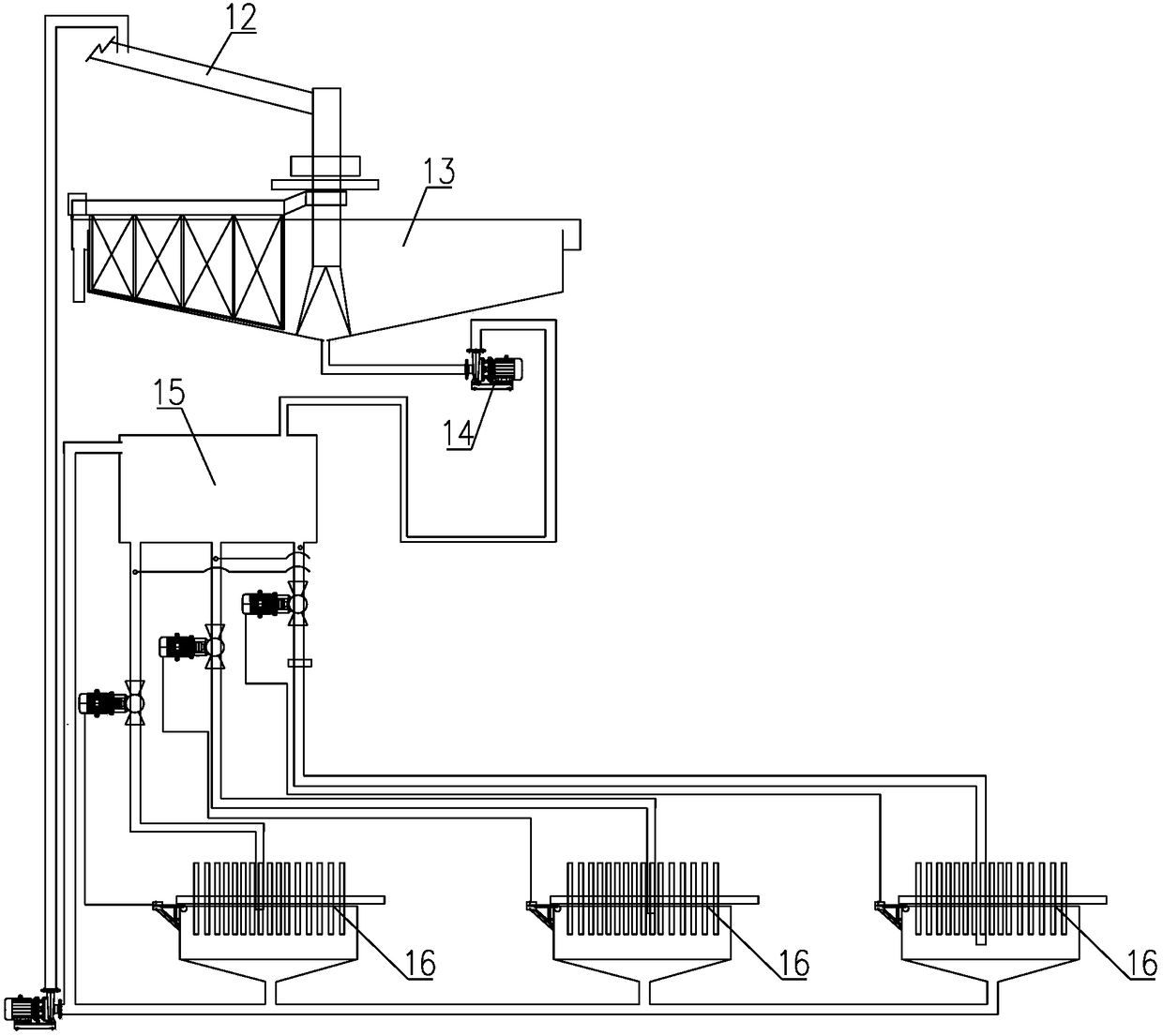

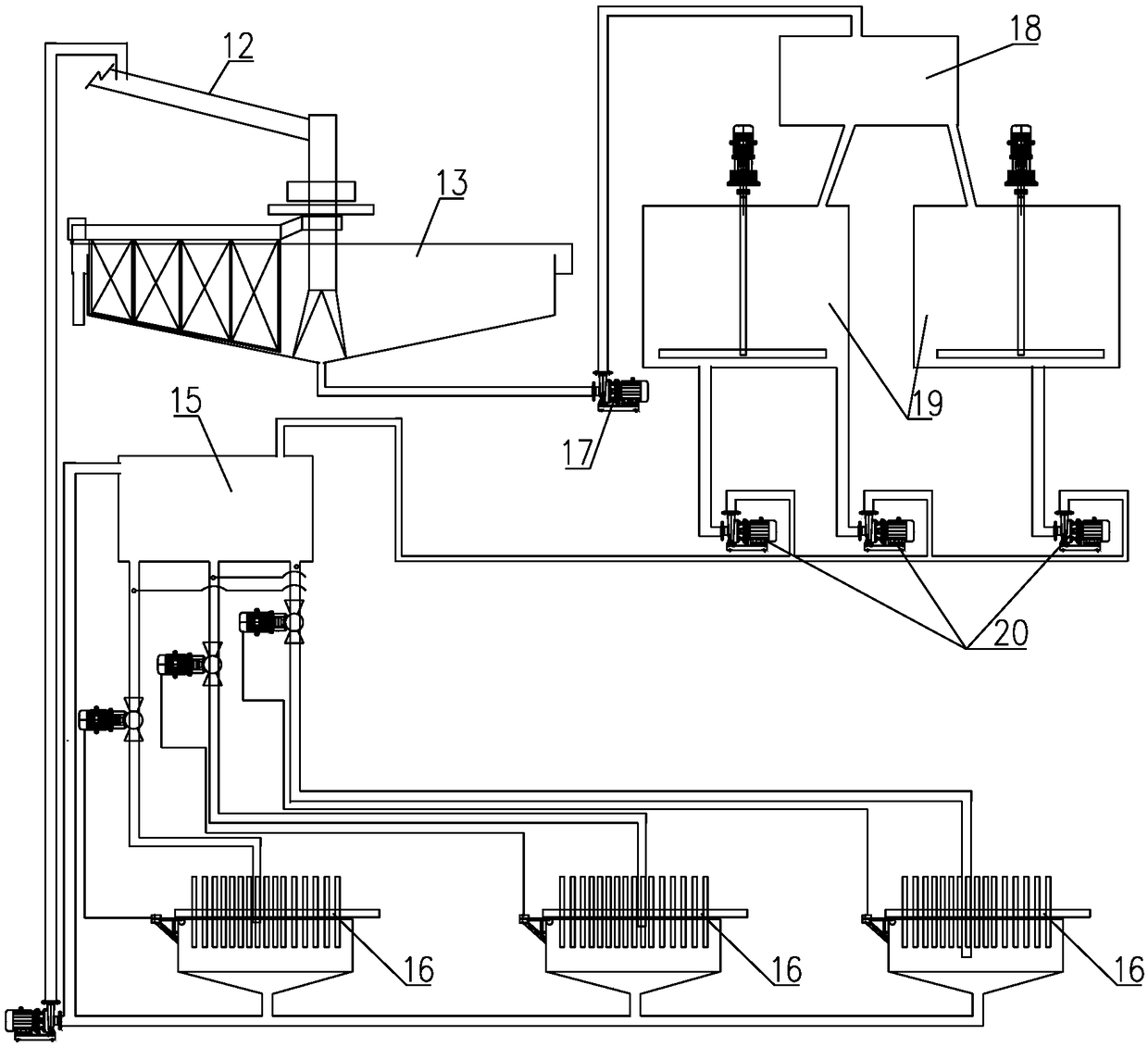

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: Get the incoming water (pH value is 10.7) of the large well of floating tail on the spot, add the calcium oxide of 100ppm, stir 1 minute, add the PAM of 3ppm again, stir 1 minute, stand for 5 minutes, clarification layer accounts for 2% of total amount 71%, ss 125 mg / l, pH 11.8.

Embodiment 2

[0065] Embodiment 2: Get the incoming water (pH value is 9.1) of the big well before the field strong magnetic field, add the calcium oxide of 50ppm, add the PAM of 3ppm again, stir 1 minute, leave standstill 5 minutes, clarification layer accounts for 78% of total amount %, ss is 112 mg / L, and its pH value is 11.1.

Embodiment 3

[0067] Embodiment 3: get water treatment unit upstream and mix into water (pH value is 9.0), add the calcium oxide of 50ppm, add the PAM of 3ppm again, stir 1 minute, leave standstill 5 minutes, clarification layer accounts for 83% of total amount, ss is 101 mg / L, its pH value is 11.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com