Siderite floatation collector and preparation thereof

A collector and siderite technology, applied in flotation, solid separation, etc., can solve the problems of relatively large impact on the collection performance of ore pulp, the difficulty of filtration and dehydration, and the decline in the quality of concentrate products, so as to achieve selective collection Strong performance, convenient sources of raw materials, and the effect of improving the grade of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Embodiment 1: Flotation of a magnesium-manganese type siderite in Anning, Yunnan Province {divided into low-copper and low-sulfur magnesium-manganese (Cu≤0.1%, S≤0.1%) and high-copper high-sulfur (Cu≥0.2%, S≥1.96 %) two kinds of magnesium manganese siderite},

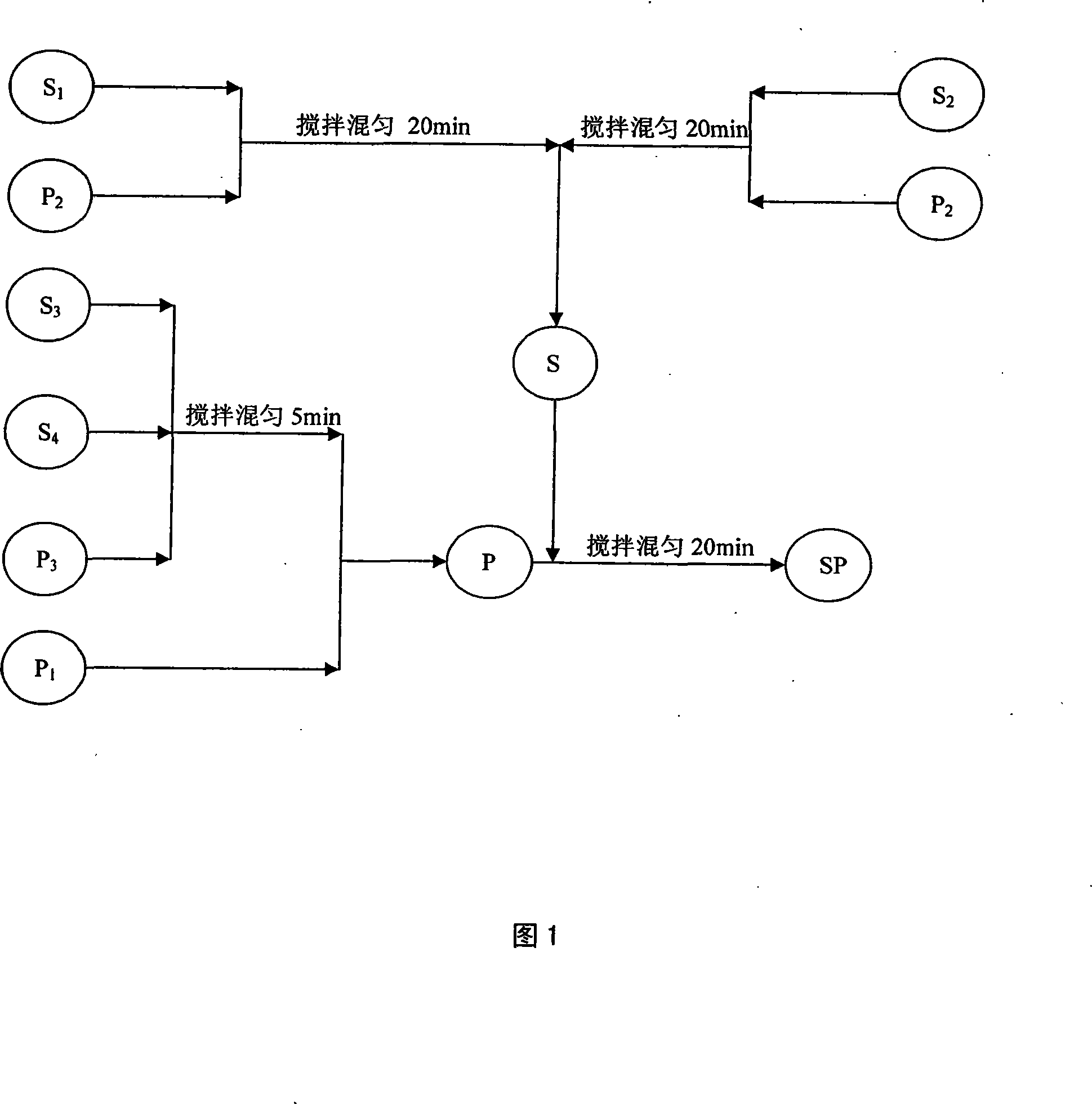

[0033] The ratio of raw materials is: S preparation ratio S 1 = 30 S 2 =30P 2 =40; P preparation ratio S 3 =20S 4 =30P 1 =10P 3 = 40; SP preparation ratio S = 60 P = 40, according to the above method to prepare the SP collector. The collector is used to replace the existing chemical system, and the test results are shown in Tables 1-2.

[0034] Table 1 Comparison of beneficiation indicators of low copper and low sulfur type magnesium manganese siderite

[0035] Collector

[0036] Table 2 Comparison of beneficiation indicators of high copper and high sulfur type magnesium manganese siderite

[0037] Collector

[0038] type

Embodiment 2

[0039] Example 2: Flotation of Yunnan Huanian siderite, the raw ore contains 30.13% TFe and 0.682% phosphorus.

[0040] The ratio of raw materials is: S preparation ratio S 1 =20S 2 = 40P 2 =40; P preparation ratio S 3 =20S 4 =30P 1 =20P 3 = 30; SP preparation ratio S = 90 P = 10, according to the above method to prepare the SP collector.

[0041] The collector was used to flotation Yunnan Huanian siderite, and the comparison results of beneficiation indicators between traditional collector and SP collector are shown in Table 3.

[0042] Table 3 Comparison of beneficiation indicators of Huaniangophos siderite

[0043] Collector

Embodiment 3

[0044] Embodiment three: Flotation of siderite in a place in Shaanxi, the raw ore contains 27.18% of TFe and 1.23% of S.

[0045] The ratio of raw materials is: S preparation ratio S 1 = 30 S 2 =30P 2 =40; P preparation ratio S 3 =20S 4 =30P 1 =10P 3 = 40; SP preparation ratio S = 60 P = 40, according to the above method to prepare the SP collector.

[0046] The collector was used to flotation siderite in a certain place in Shaanxi, and the comparison results of beneficiation indicators between traditional collector and SP collector are shown in Table 4.

[0047] Table 4 Comparison of siderite beneficiation indicators in a certain place in Shaanxi

[0048] Collector

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com