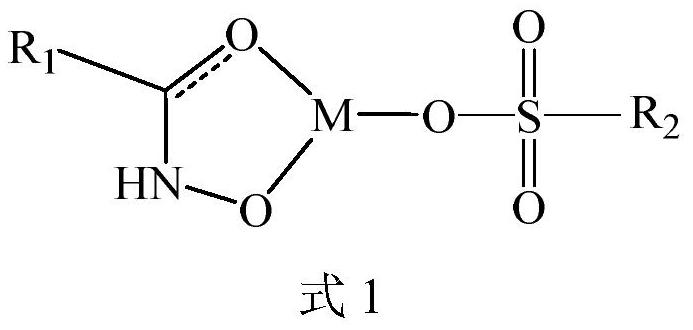

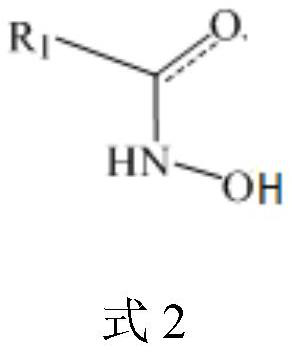

Hydroxamic acid-sulfonic acid multi-ligand metal complex collector and its preparation method and application

A metal complex and hydroxamic acid technology, which is applied in the field of hydroxamic acid-sulfonic acid multi-ligand metal complex collectors and flotation collectors, can solve the problem of large amount of inhibitors, titanium-containing minerals and gangue Difficult separation of minerals, low recovery rate and other problems, to achieve the effect of large-scale production and application, reduce the cost of mineral processing, and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

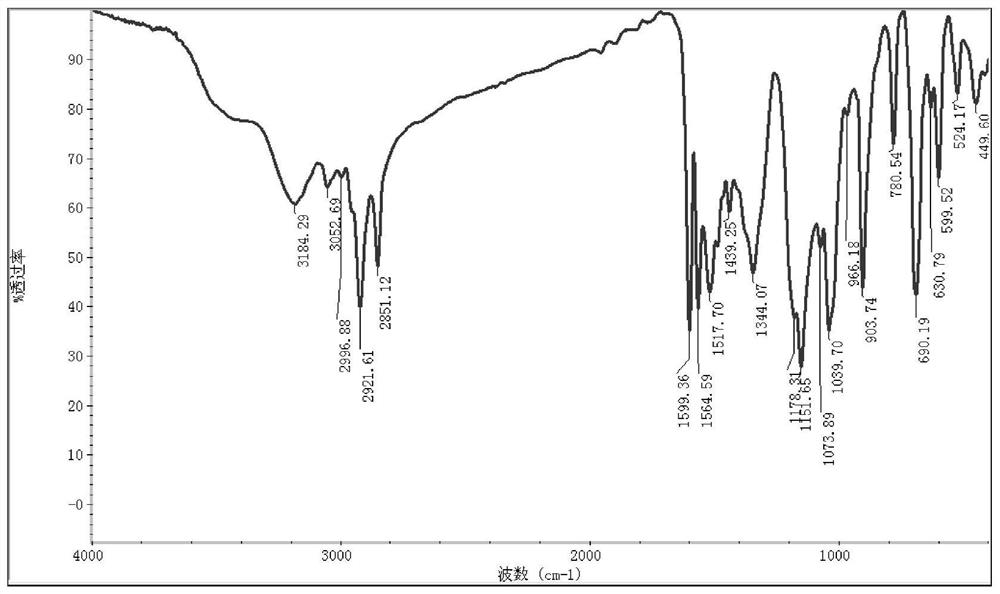

Image

Examples

Embodiment 1

[0051] Weigh 0.001mol of benzohydroxamic acid and put it into a 500mL flask, add 300mL of methanol as a solvent, add 0.0002mol of ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 9.5, and stir the reaction at room temperature for 25min. Obtain hydroxamate; Hydroxamate and n-octadecyl sodium sulfonate are added in the flask according to the molar mass ratio of 1:1, add glycerin to make its mass concentration be 40%, then be placed in the constant temperature water bath, use magnetic Stirring and heating to 85°C and reacting for 25 minutes, the obtained liquid was recrystallized three times after rotary evaporation to obtain a solid; the obtained solid was added to the flask, and the mixed liquid of water and methanol was prepared according to the volume ratio of water and methanol at 7:1 and added In the flask, the mass percent concentration of the solid in the mixed solution of water and methanol is 35%, to obtain hydroxamic acid-alk...

Embodiment 2

[0056] Weigh 0.002mol of propyl hydroxamic acid and put it into a 500mL flask, add 300mL of methanol as a solvent, add 0.0004mol of ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 8.0, stir and react at room temperature for 30min, Obtain hydroxamate; Hydroxamate and sodium dodecylsulfonate add in the flask according to the molar mass ratio of 1.5:1, add glycerin and make its mass concentration be 38%, then be placed in the constant temperature water bath, use magnetic Stir and heat to 80°C and react for 30 minutes. The obtained liquid is recrystallized three times after rotary evaporation to obtain a solid; add the obtained solid to the flask, and prepare a mixed liquid of water and methanol according to the volume ratio of water and methanol at 8:1. Add it into a flask so that the mass percentage concentration of the solid in the mixed solution of water and methanol is 45%, to obtain hydroxamic acid-alkylsulfonic acid multiligand c...

Embodiment 3

[0062] Weigh 0.001mol of benzohydroxamic acid and put it into a 500mL flask, add 300mL of methanol as a solvent, add 0.0002mol of ethyl acetate after complete dissolution, then add sodium hydroxide to adjust the pH value to 9.0, and stir and react at room temperature for 30min. Obtain hydroxamate; hydroxamate and sodium dodecylbenzenesulfonate are added in the flask according to the molar mass ratio of 1:1, add glycerin to make its mass concentration be 35%, then be placed in the constant temperature water bath, use Stir with a magnet and heat to 90°C and react for 30 minutes. The obtained liquid is recrystallized three times after rotary evaporation to obtain a solid; add the obtained solid to the flask, and prepare a mixed liquid of water and methanol according to the volume ratio of water and methanol at 6:1. The mixture is added into a flask so that the mass percent concentration of the solid in the mixed solution of water and methanol is 40%, and the hydroxamic acid-alkyls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com