A kind of scheelite collector and its preparation method and application

A collector and scheelite technology, applied in solid separation, flotation, etc., can solve the problems of poor selective collection effect and high price of chemicals, achieve low cost, solve serious impacts, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] For waste oil containing 10% palmitic acid, 10% octadecanoic acid, 40% oleic acid and 15% linoleic acid, after filtering out impurities, proceed according to the following steps and methods:

[0016] (1) Add 3 parts of 10% H 2 SO 4 Solution, after stirring for 30 minutes, washed with water twice;

[0017] (2) Stand still for 10 hours, take the upper organic phase;

[0018] (3) Add 1 part of Tween-80 to 20 parts of organic phase and stir for 1 hour to obtain scheelite collector.

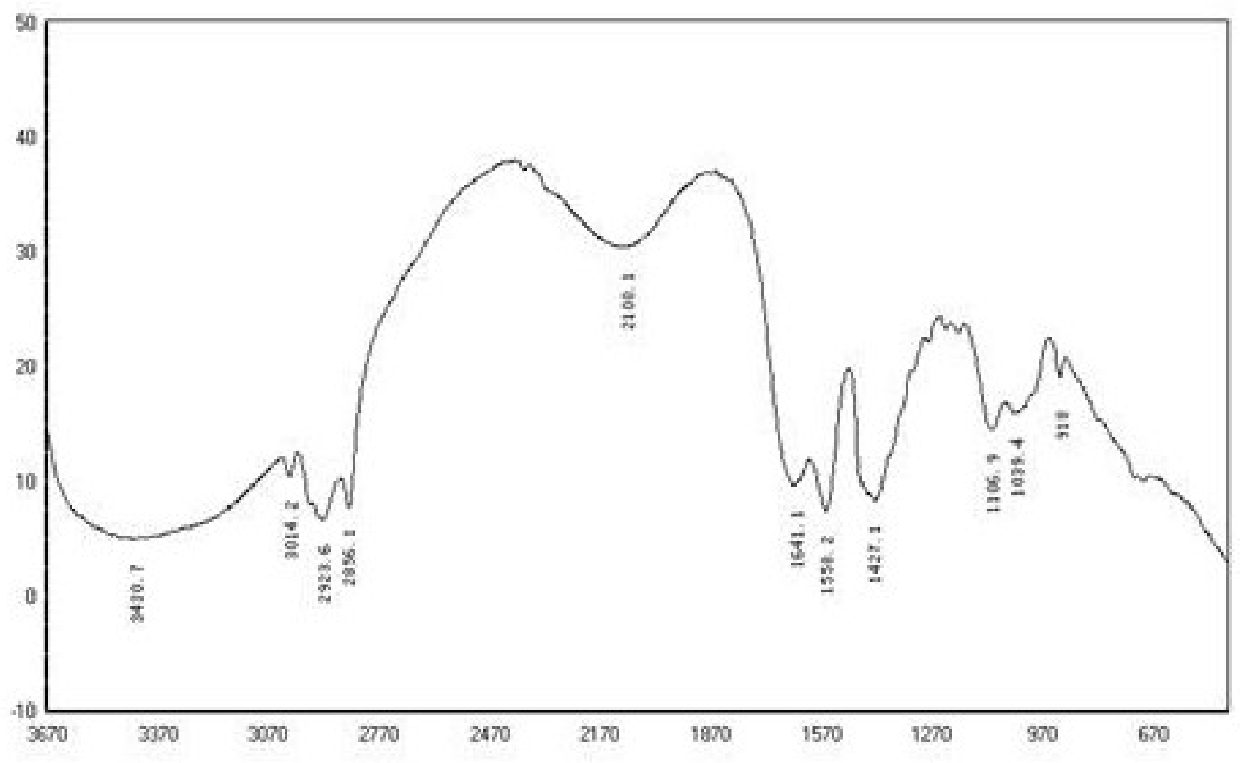

[0019] The scheelite collector prepared in this example is a light yellow to brownish red liquid, soluble in water at a temperature ≥ 10°C, and the aqueous solution is a transparent light yellow solution with a water solubility of 3%. Its infrared spectrum is shown in figure 1 Shown, the absorption peak (cm -1 ): 3430.7, 3104.2, 2923.6, 2856.1, 2100.1, 1641.1, 1558.2, 1427.1, 1106.9, 1039.4, 918.

Embodiment 2

[0021] For waste oil containing 40% palmitic acid, 5% octadecanoic acid, 10% oleic acid and 30% linoleic acid, first filter out impurities, and then proceed according to the following steps and methods:

[0022] (1) Add 1 part of 30% H 2 SO 4 Solution, after stirring for 30 minutes, washed with water 3 times;

[0023] (2) Stand still for 5 hours, take the upper organic phase;

[0024] (3) Add 2 parts of TX-10 to 20 parts of organic phase and stir for 0.8 hours to obtain scheelite collector.

[0025] The scheelite collector prepared in this example is a light yellow to brownish red liquid, soluble in water at a temperature ≥ 10°C, and the aqueous solution is a transparent light yellow solution with a water solubility of 5%.

Embodiment 3

[0027] For waste oil containing 30% palmitic acid, 7% octadecanoic acid, 35% oleic acid and 10% linoleic acid, first filter out impurities, and then proceed according to the following steps and methods:

[0028] (1) Add 2 parts of 20% H 2 SO 4 Solution, after stirring for 30 minutes, washed with water 3 times;

[0029] (2) Stand still for 20 hours, take the upper organic phase;

[0030] (3) Add 3 parts of Tween-80 to 20 parts of organic phase and stir for 0.5 hours to obtain scheelite collector.

[0031] The scheelite collector prepared in this example is a light yellow to brownish red liquid, soluble in water at a temperature ≥ 10°C, and the aqueous solution is a transparent light yellow solution with a water solubility of 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com