Magnetoelectricity sorting method and equipment of multiple element mineral

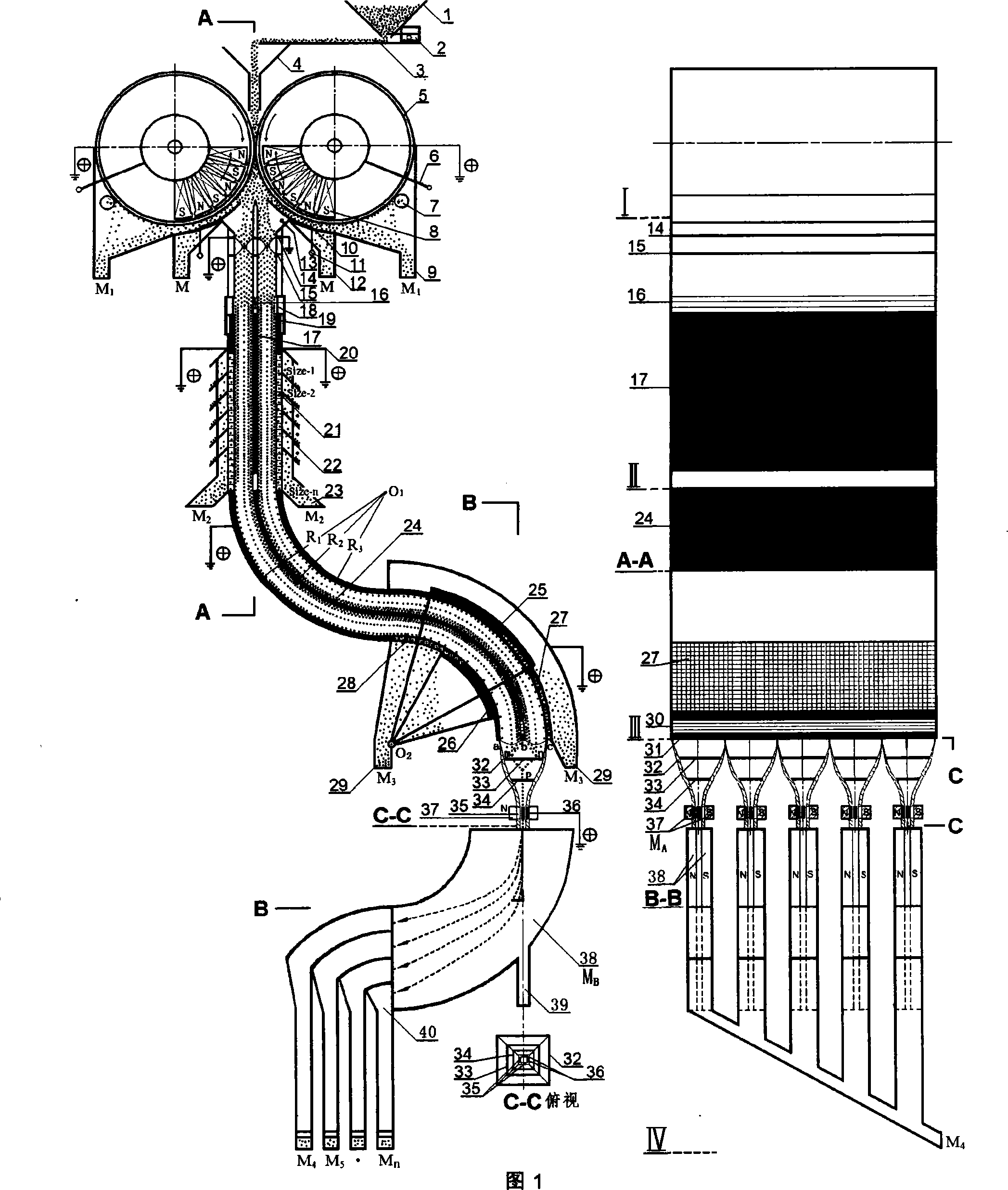

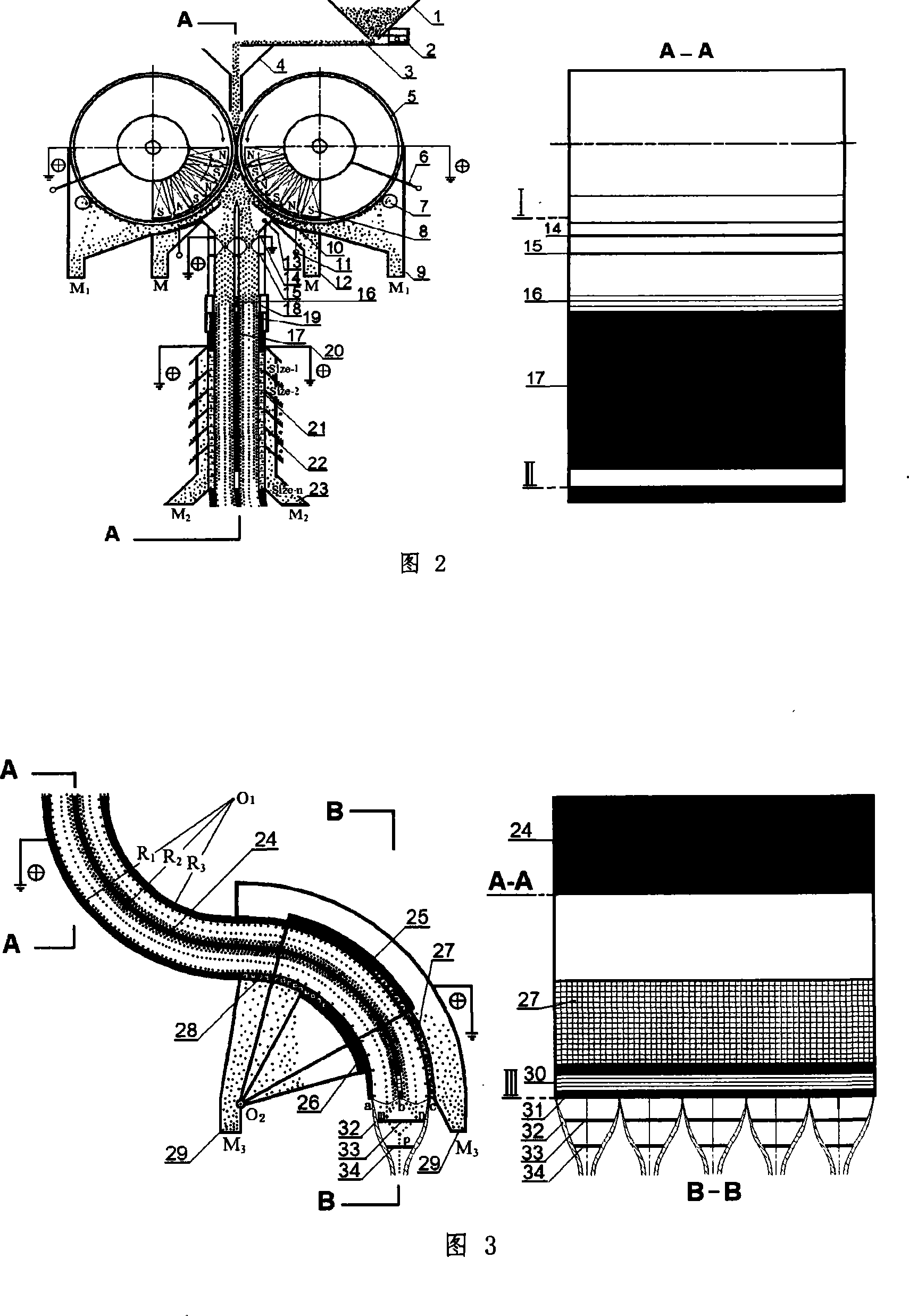

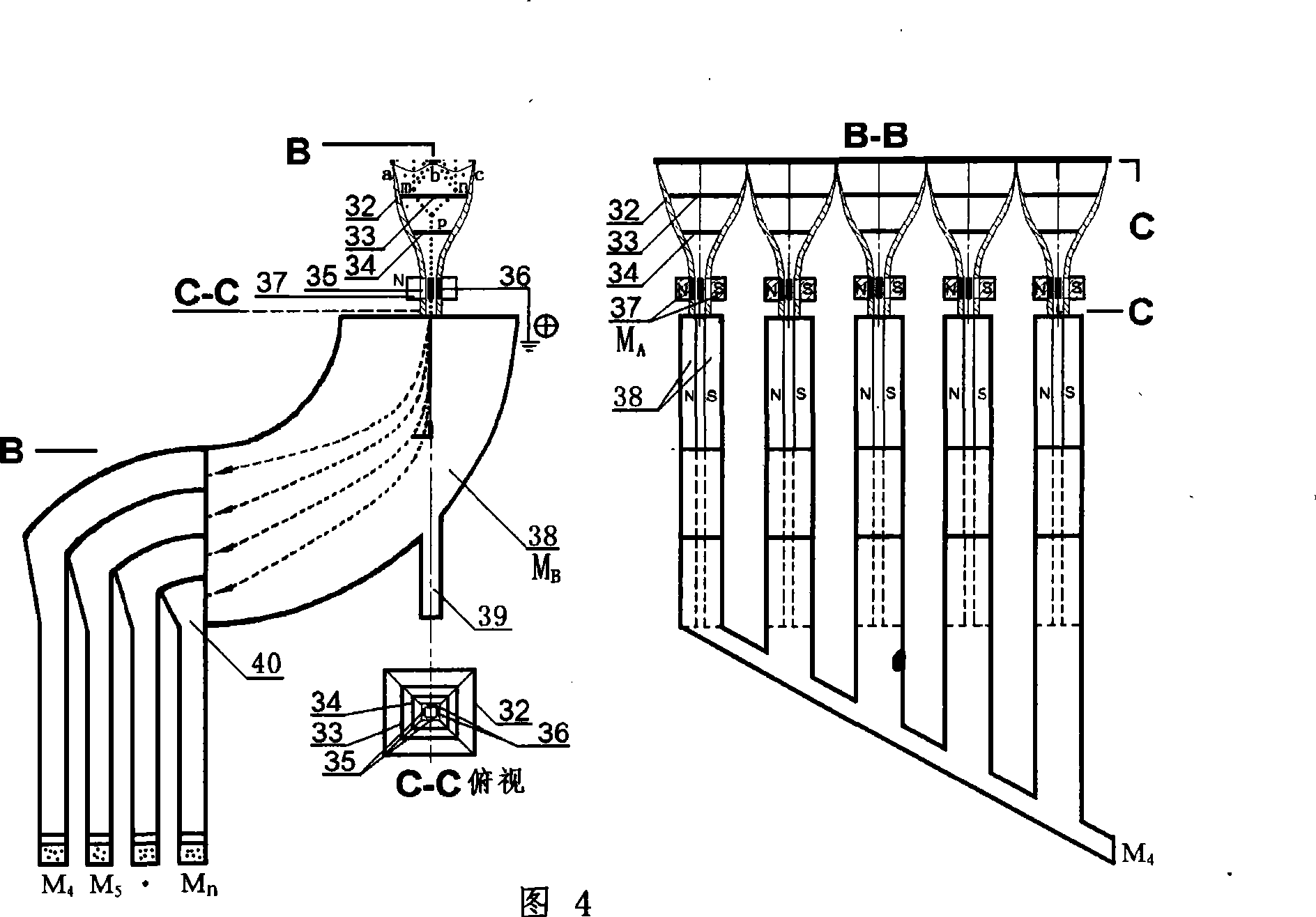

A kind of mineral separation technology, applied in mineral processing technology and mineral processing equipment, magnetoelectric combined separation field, can solve problems such as low recovery rate, low grade iron concentrate, and inability to separate harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0139] 1. Mineral processing test of Shouwangfen copper-iron mine in Hebei Province

[0140] The mine is a skarn-type copper-iron deposit. Ore is divided into three categories:

[0141] (1) White ore (talc, actinolite, diopside contains copper, and the color is whitish), the metal mineral intercalation particle size is coarse, and the selectability is good;

[0142] (2) Black ore (serpentine, magnetite containing copper, black in color), the ore is dense in texture, strong in toughness, and the distribution of metal minerals is fine, so it is a refractory ore;

[0143] (3) Magnetite copper-containing ore has high hardness, high density, brittle texture, and coarse metal mineral intercalation, which is a medium optional ore.

[0144] Metal minerals in the ore include magnetite, pyrrhotite, hematite, chalcopyrite, azurite, black copper ore, malachite, aluminum pyroxene, sphalerite, sulfur cobalt ore, gold and silver ore, silver Gold ore, silver-silver ore, native gold, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com