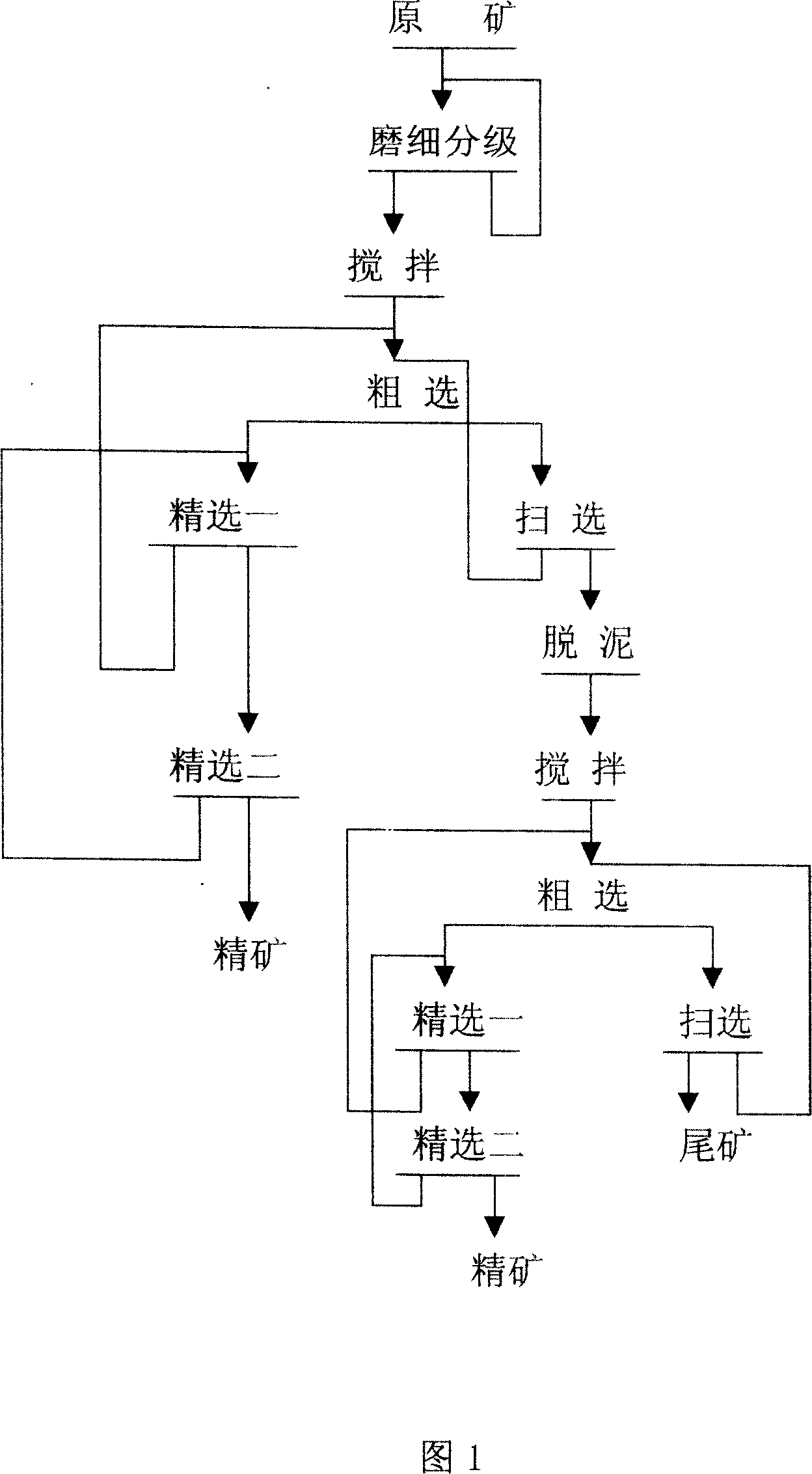

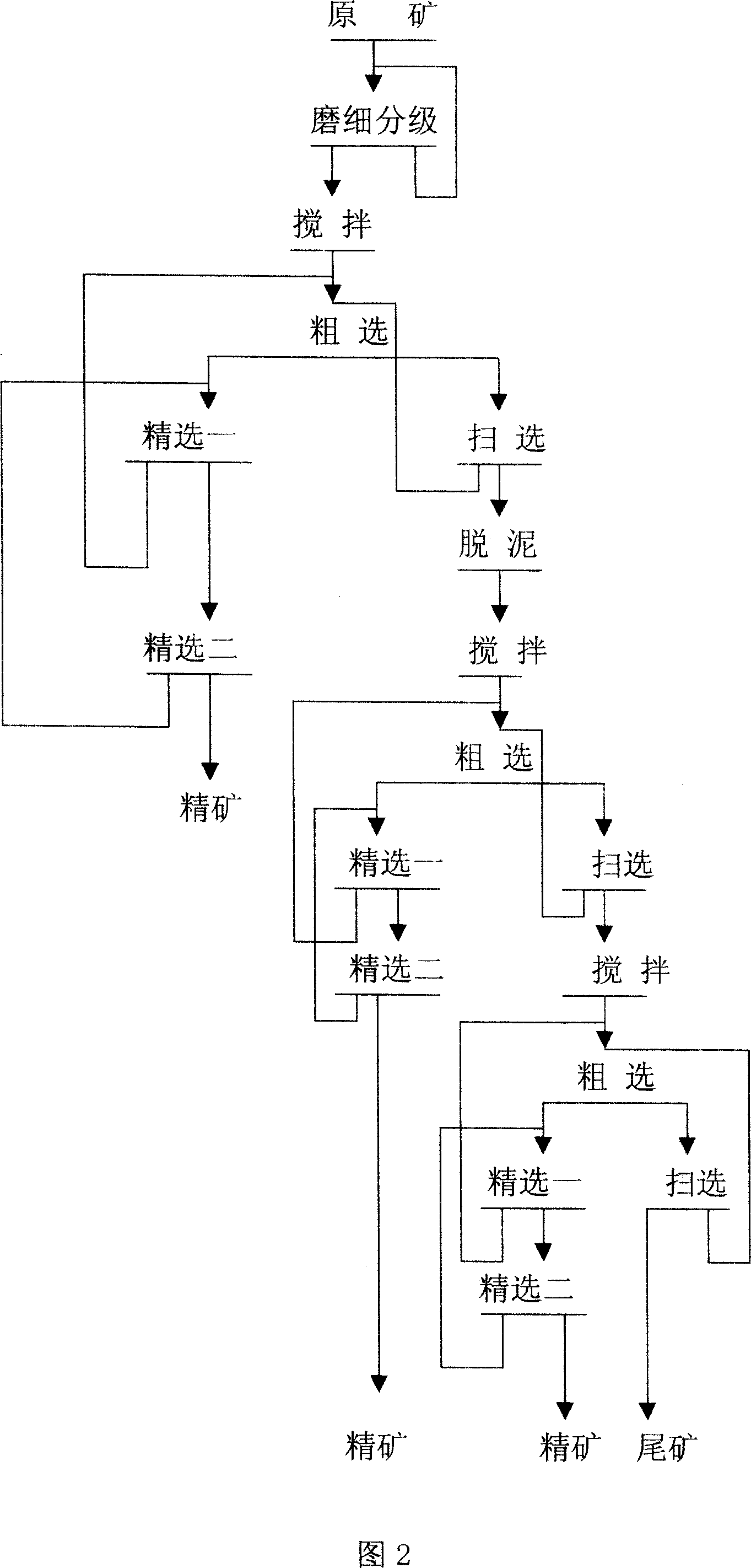

Beneficiation method of complex copper oxide ore

A technology of copper oxide ore and mineral processing methods, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of poor efficiency, low economic indicators, low recovery rate of complex copper oxide ore, etc., and achieve improved recovery rate , Improve the grade of concentrate and reduce the effect of copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Take Tangdan Copper Oxide Mine in Dongchuan, Yunnan Province, the raw ore grade is 1.56%. The specific process steps are as follows:

[0077] 1. Grind and classify the above-mentioned copper oxide ore so that 80% of the particles have a particle size of -0.074mm, control the pH value to 8.5 and the concentration to 35%, and add the following flotation agents:

[0078] Gangue inhibitor: sodium carbonate 200g / t, water glass 500g / t, calcium lignosulfonate 200g / t;

[0079] Activator: sodium sulfide 500g / t;

[0080] Composite collector emulsion: mercaptobenzothiazole 12g / t, sodium hydroxide 6g / t, butyl xanthate 100g / t, butyl ammonium black medicine 50g / t, edetate disodium 20g / t, diesel oil 50g / t, alkanolamide 10g / t; and obtained through the following method: earlier sodium hydroxide is formulated into a solution with a concentration of 10%, then mercaptobenzothiazole is added to the solution, then butyl xanthate and Butyl ammonium black medicine, then add disodium edetat...

Embodiment 2

[0084] Take copper oxide mine in Lanping County, Yunnan Province, the raw ore grade is 0.96%, and the gangue composition is iron silicate. The specific process steps are as follows:

[0085] 1. Grind and classify the above-mentioned copper oxide ore so that 80% of the particle size is -0.074mm, control the pulp concentration to 30%, and the pH value of the pulp to 11, and add the following gangue inhibitors: lime 1kg / t, water glass 500g / t , carmellose 200g / t; activator: sodium sulfide 1kg / t; composite collector: mercaptobenzothiazole 20g / t, sodium hydroxide 20g / t, butyl xanthate 150g / t, butylammonium black medicine 70g / t, ethyl disulfide 50g / t, disodium edetate 20g / t, gasoline 150g / t, alkylphenol polyoxyethylene 50g / t; stir for 15 minutes, conduct primary group roughing for 8 minutes , the concentrated ore after the primary group roughing is subjected to a 2-minute selection, and then a second 1-minute selection to obtain a grade of 18.9% of the primary group concentrate prod...

example 3

[0088] Take a certain copper oxide ore in Lanping County, Yunnan Province, its grade is 3.25%, through the following process steps:

[0089] 1. Grind and classify the above-mentioned copper oxide ore, so that 80% of the particle size is -0.074mm, control the pH value of the slurry to 12, and the concentration of the slurry to 24%, and add the following gangue inhibitors: sodium carbonate 500g / t, water glass 1000g / t t, calcium lignosulfonate 300g / t; activator: sodium sulfide 3kg / t, ammonium sulfate 1kg / t, dithiol dithioazole 1kg / t; compound collector emulsion: mercaptobenzothiazole 30g / t t, sodium hydroxide 40g / t, butyl xanthate 250g / t, butylammonium black medicine 80g / t, ethiazide 60g / t, disodium edetate 20g / t, gasoline 100g / t, alkyl Alcohol amide 20g / t (the preparation method of composite collector emulsion is the same as the 1st step of embodiment 1), stirred for 12 minutes, carried out the primary group roughing for 10 minutes, and the concentrate after the roughing was car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com