Efficient flotation separation method of copper sulfide ores

A technology of copper sulfide ore separation method, applied in flotation, solid separation, etc., can solve the problems of unstable chemical properties of sulfur and nitrogen, aggravate the degree of mechanical inclusion, increase the degree of mechanical inclusion, etc., achieve good beneficiation indicators, and reduce sensitivity , The effect of low drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

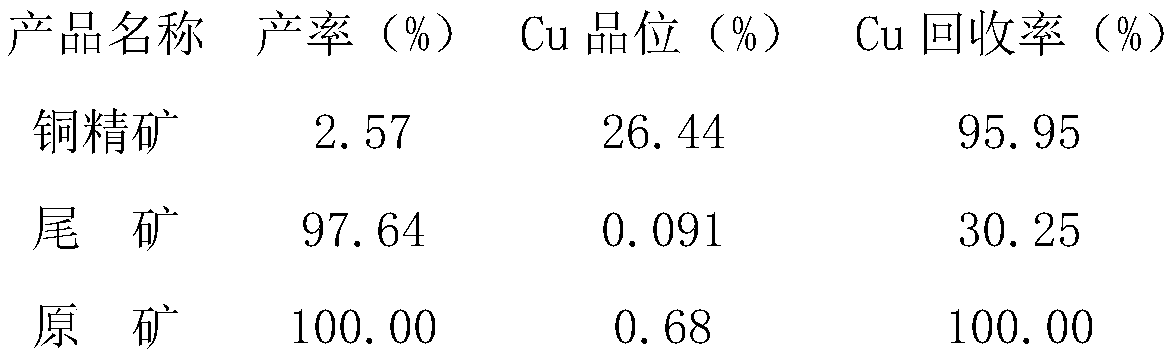

[0023] The raw ore contains 0.28% Cu by mass, and the gangue minerals are mainly quartz, sericite, chlorite and pyrrhotite.

[0024] The particle size of the grinding product is less than 0.074mm, accounting for 70% by mass, the pulp concentration is adjusted to 40% by mass, and 1000g / t of calcium oxide is added to realize the inhibition of pyrrhotite, which is achieved by adding a combination regulator of 172g / t For pulp dispersion and suppression of gangue minerals, 73g / t was added for flotation. After the closed-circuit process of "one rough, one sweep, two fine, and medium ore returned sequentially", the test indicators obtained are shown in Table 1.

[0025] Wherein said combined regulator includes: sodium sulfide 60g, sodium hexametaphosphate 80g and sodium humate 32g, said combined collector includes the following components by weight: alkyl xanthate propionitrile 20g, xanthate diester 15g , butyl ammonium black medicine 8g, methyl benzyl disulfide 15g and terpene alcoh...

Embodiment 2

[0036] The difference with Example 1 is:

[0037] The combined regulator includes: 80g of sodium hexametaphosphate and 32g of sodium humate, and the combined collector includes the following components in parts by weight: 20g of propionitrile alkyl xanthate, 15g of xanthate diester, butylammonium black medicine 8g, 15g of methyl benzyl thiazepine and 15g of terpene alcohol. The experimental indicators obtained are shown in Table 3.

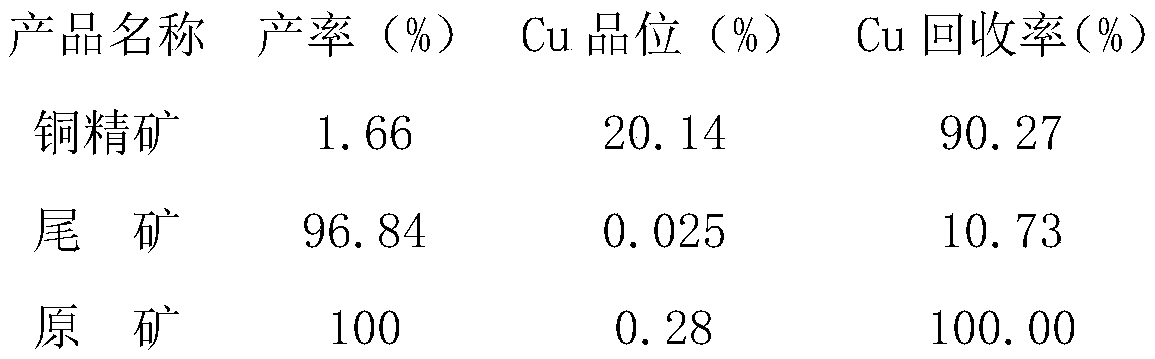

[0038] Table 3 Flotation separation index of copper sulfide ore

[0039]

Embodiment 3

[0041] The difference with Example 1 is:

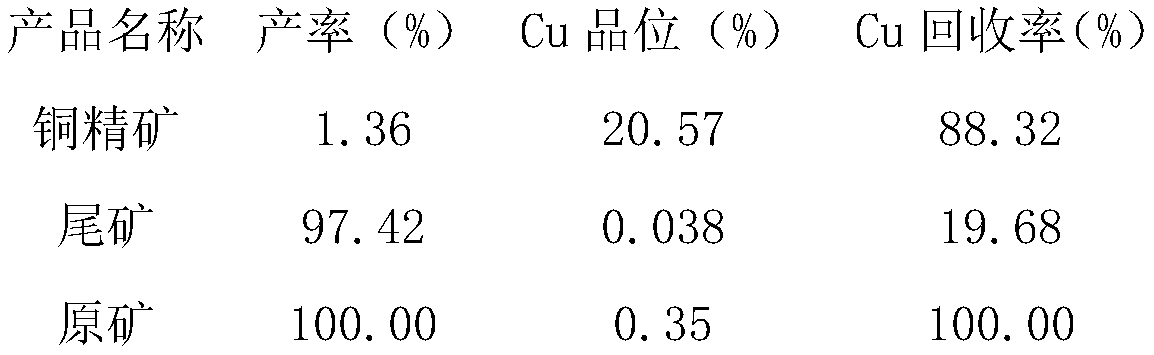

[0042] The combined regulator includes: 80 g of sodium hexametaphosphate and 32 g of sodium humate, and the combined collector includes the following components in parts by weight: 30 g of alkyl xanthate propionitrile, 20 g of methyl benzylsulfazine And terpene alcohol 20g, obtain test index and see Table 4.

[0043] Table 4 Copper sulfide ore flotation separation index

[0044]

[0045] In combination with the above examples, it can be seen that the present application effectively improves the Cu recovery rate by rationally adjusting the combination regulator and the combination collector. The combination of sodium sulfide, sodium hexametaphosphate and sodium humate can effectively improve the flotation effect. Xanthate diester and butyl ammonium black drug can interact with alkyl xanthate propionitrile, methyl benzyl sulfazate and terpene alcohol paracetamol to improve the collection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com