Flotation agent for flotation of kustelite and flotation method

A flotation agent and flotation technology, used in flotation, solid separation and other directions, can solve the problems of long-term reuse of tailings water, difficulty in sedimentation of ore pulp, and inability to reuse tailings water, etc., to improve the quality and recovery. rate, strong inhibitory effect, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

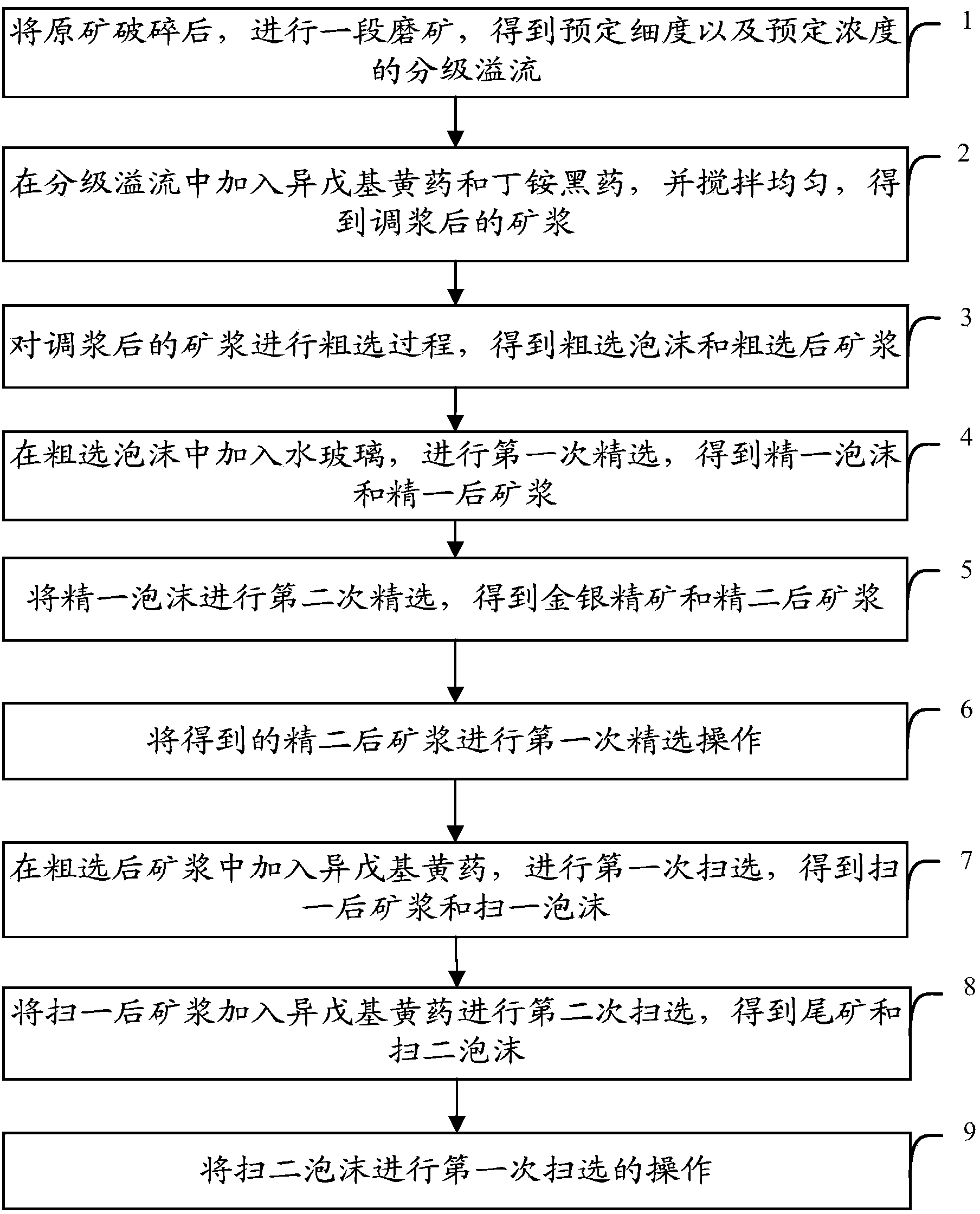

Method used

Image

Examples

Embodiment 2

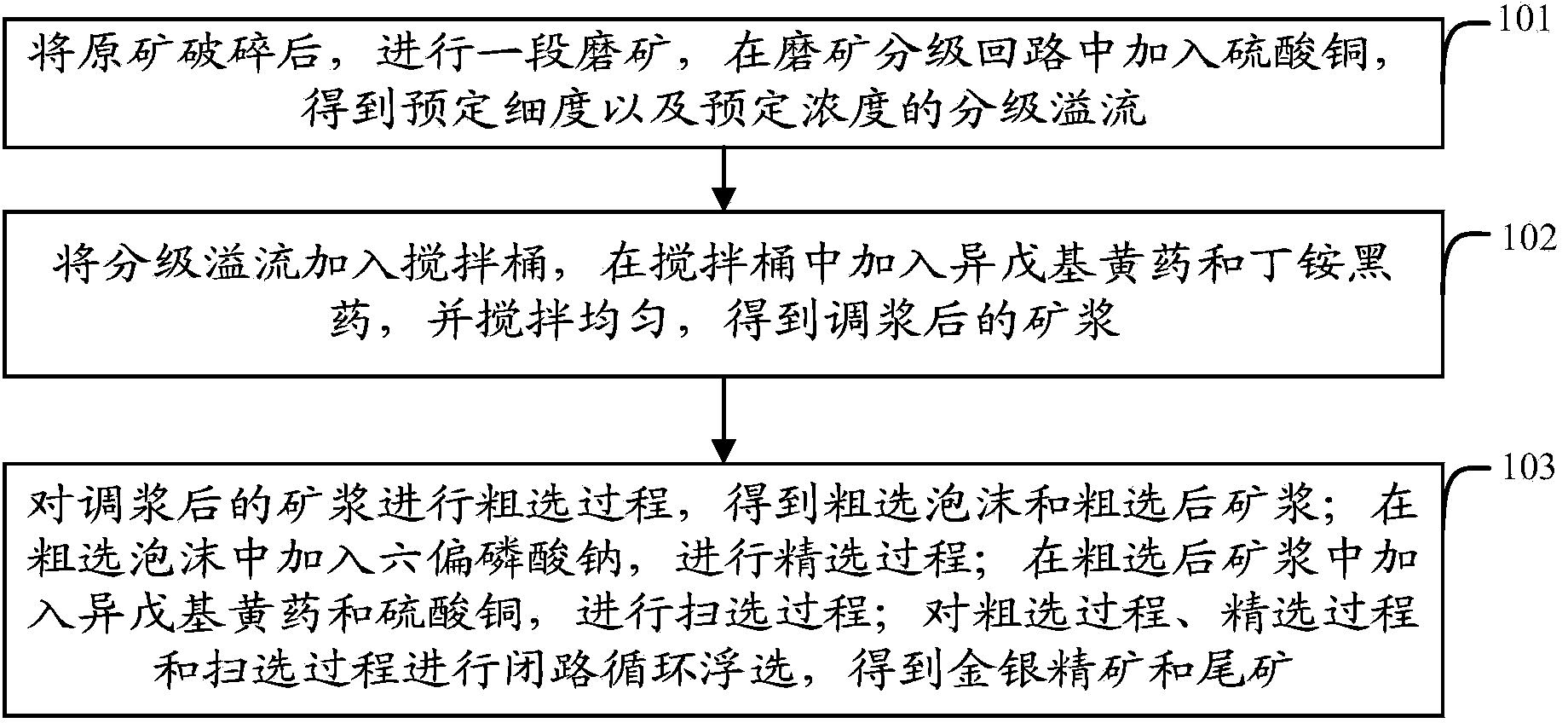

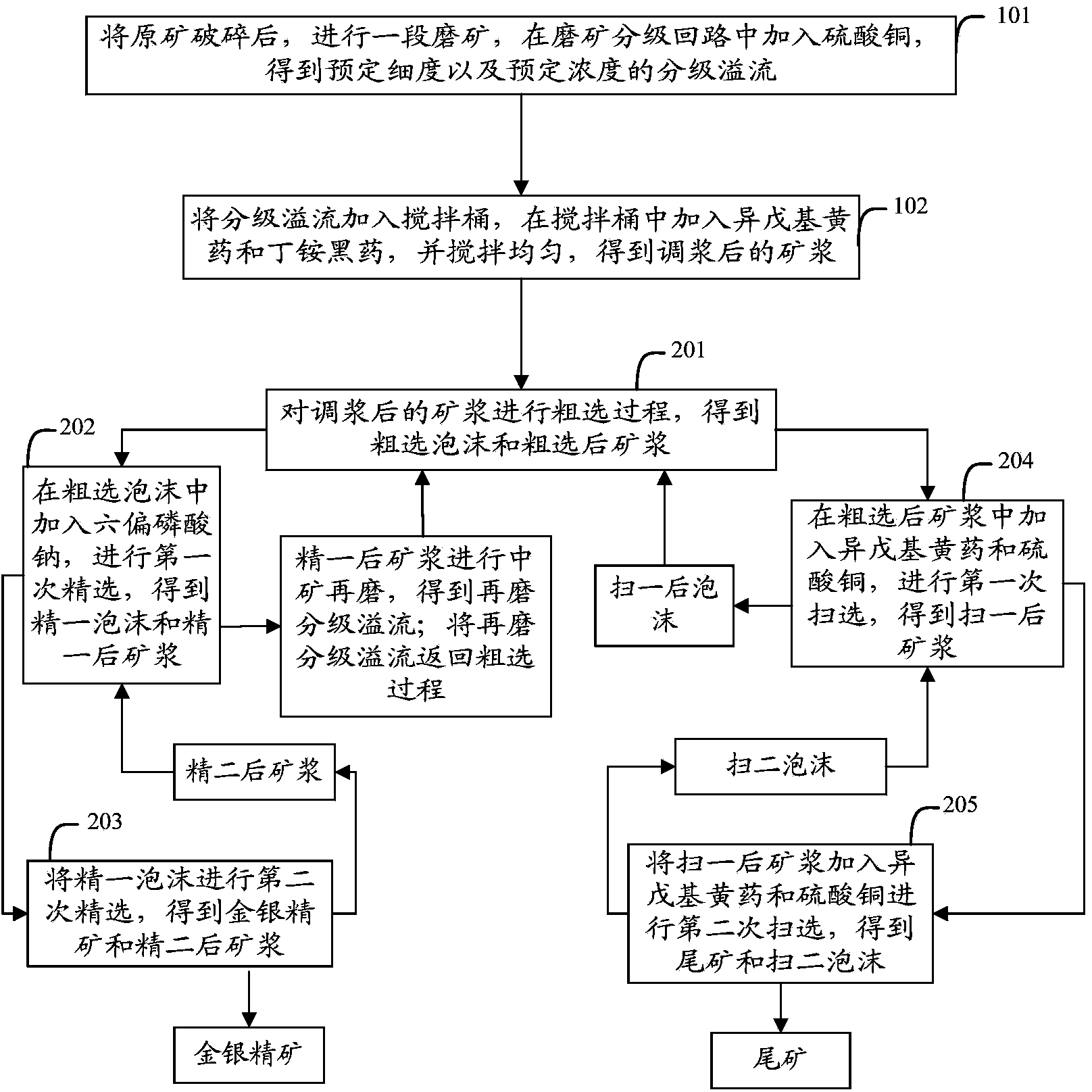

[0030] In this embodiment, the steps of the first embodiment are specifically refined and described in detail. For example, in step 103 of the first embodiment, the specific operations adopt a closed-loop process, which specifically includes the following steps:

[0031] Step 201: performing a roughing process on the adjusted pulp to obtain roughing foam and roughed pulp;

[0032] Specifically, the roughing process can be realized through a flotation machine with 4 slots of SF4 cubic meters. During the roughing process, a large amount of gold and silver particles float up with the roughing foam, and can be used for the subsequent selection process. After roughing, the ore pulp can enter the subsequent sweeping process.

[0033] Step 202: adding sodium hexametaphosphate to the roughing foam for the first beneficiation to obtain refined foam and refined pulp;

[0034] Specifically, the first selection process can be realized through a type A 2.8 cubic flotation machine.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com