Method for separating high-content carnosic acid from rosemary

A carnosic acid, high-content technology, applied in the separation/purification of carboxylic acid compounds, bulk chemical production, organic chemistry, etc., can solve the problem of solvent volume reduction, achieve strong continuity, improve extraction efficiency, and simple method easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

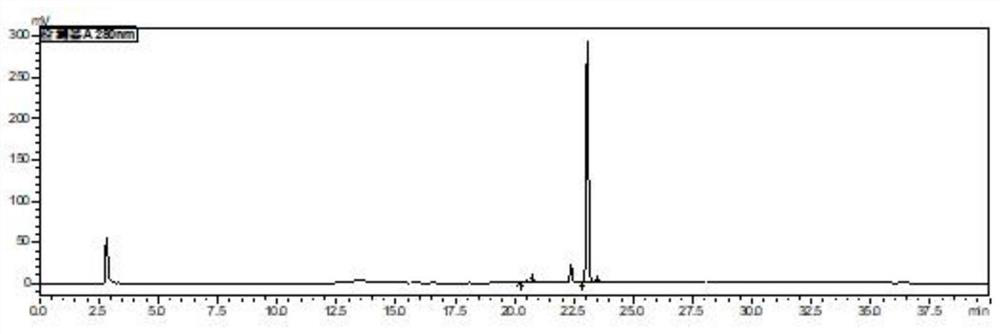

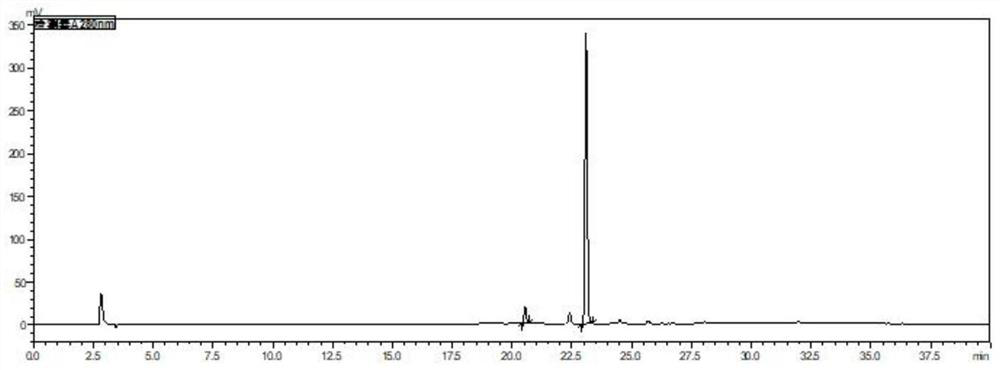

Image

Examples

Embodiment 1

[0036] A production method for isolating and purifying carnosic acid from rosemary, the steps comprising:

[0037] 1) First put 60wt% ethanol into the screw main pusher of the equipment, turn on the steam switch of the equipment to raise the temperature, and when the temperature in the equipment is measured to be 50°C, take 20kg of dried rosemary leaves and feed them from the feeding port of the equipment. The speed is 8.0r / min, the speed of the screw main propeller is 20%, the addition of 60wt% ethanol is 90L, 40g of activated carbon is divided into 4 times and added once every 10min from the feed port, and the extraction time is 50min; After the mesh sieve flows out, use a diaphragm pump to pump into a precision filter equipped with a nanofiltration membrane to filter the filtrate to 80L. Concentrate under reduced pressure at 70°C to 6L, stop the concentration, and filter after cooling to obtain 1.5kg of paste A;

[0038] 2) Paste A was dissolved in 15L petroleum ether and eth...

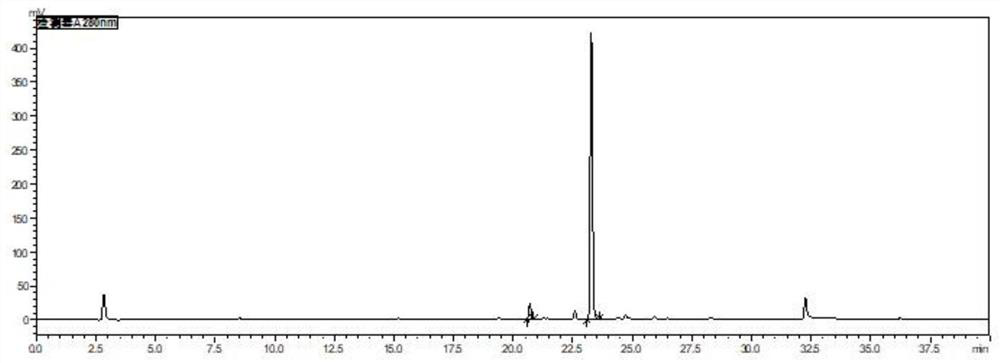

Embodiment 2

[0046] A production method for isolating and purifying carnosic acid from rosemary, the steps comprising:

[0047] 1) First put 70wt% ethanol into the screw main pusher of the equipment, turn on the steam switch of the equipment to raise the temperature, and when the temperature in the equipment is measured to be 50°C, take 20kg of dried rosemary leaves and feed them from the feeding port of the equipment. The speed is 8.5r / min, the speed of the screw main propeller is 23%, the addition of 70wt% ethanol is 66L, 55g activated carbon is divided into 5 times and added once every 11min from the feed port end, and the extraction time is 55min; After the mesh sieve flows out, use a diaphragm pump to filter into a precision filter equipped with a nanofiltration membrane to obtain 60L of filtrate. Concentrate under reduced pressure at 70°C to 4L, stop the concentration, and filter after cooling to obtain 1.6kg of paste A;

[0048] 2) Paste A is dissolved in a mixed solvent of 32L of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com