Efficient flotation reagent for fine-grained sphalerite separation, preparation method and application thereof

A technology of flotation agent and sphalerite, which is applied in flotation, solid separation, etc., to achieve the effect of simple use, obvious effect and low agent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the medicament is to prepare the above-mentioned four kinds of raw materials into corresponding concentrations according to the content of the above-mentioned formula, and then mix them according to a certain ratio.

[0025] The use method of the medicament is the solution prepared in the above manner, and the prepared medicament is directly added for the roughing operation in the sphalerite flotation operation.

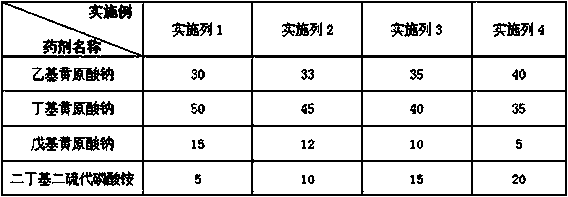

[0026]

[0027] Prepare the medicament according to the preparation method in the above table, wherein: 1 part of sodium ethyl xanthate; 1 part of sodium butyl xanthate; 1 part of sodium amyl xanthate; 1 part of dibutyl ammonium dithiophosphate. The above 4 kinds of raw materials are prepared into corresponding concentrations and mixed according to the proportion.

[0028] The method of using the medicament is the solution prepared in the above way, and the prepared medicament can be directly added to the sphalerite roughing operat...

Embodiment 1-4

[0030] Examples 1-4 are tailings after mixed separation of lead and sulfur, and the grades of sphalerite in the zinc separation process are not the same.

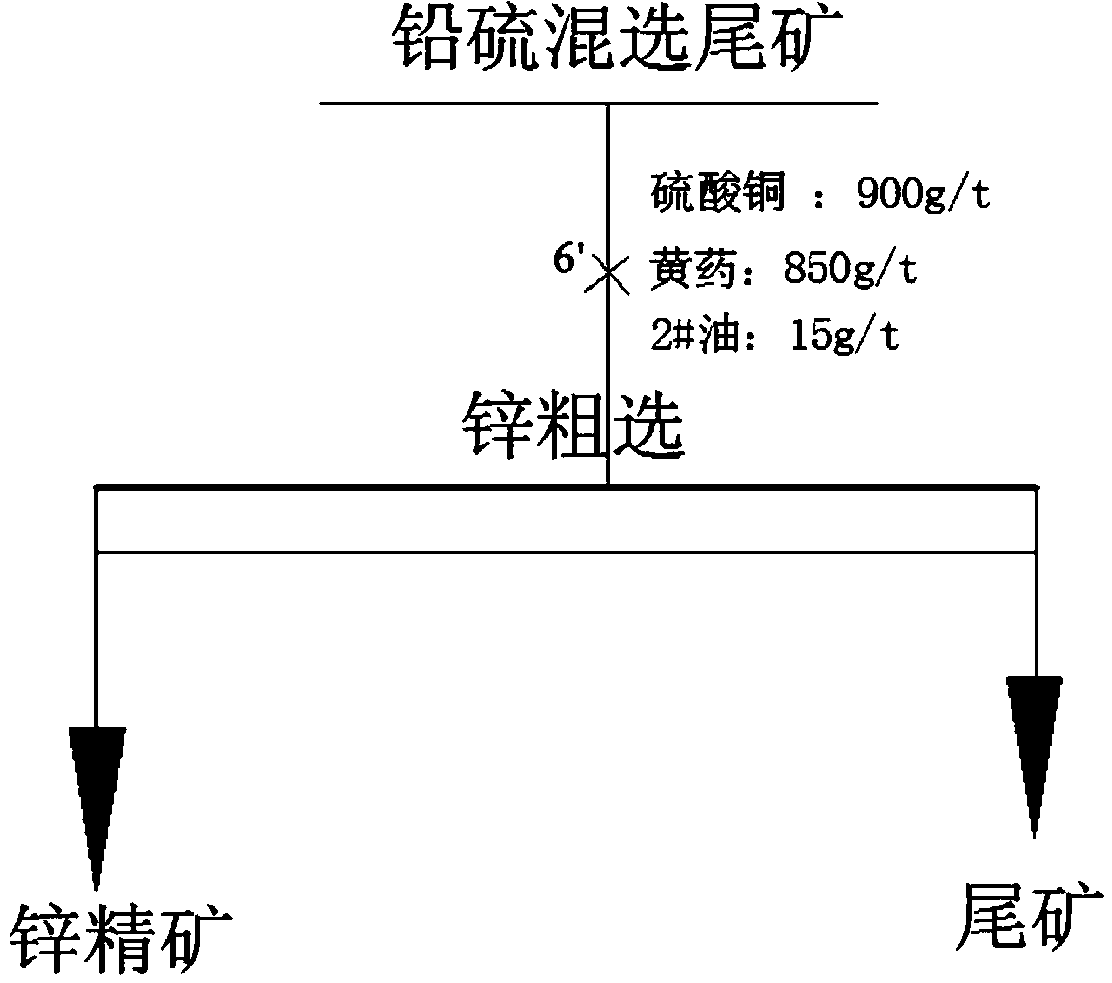

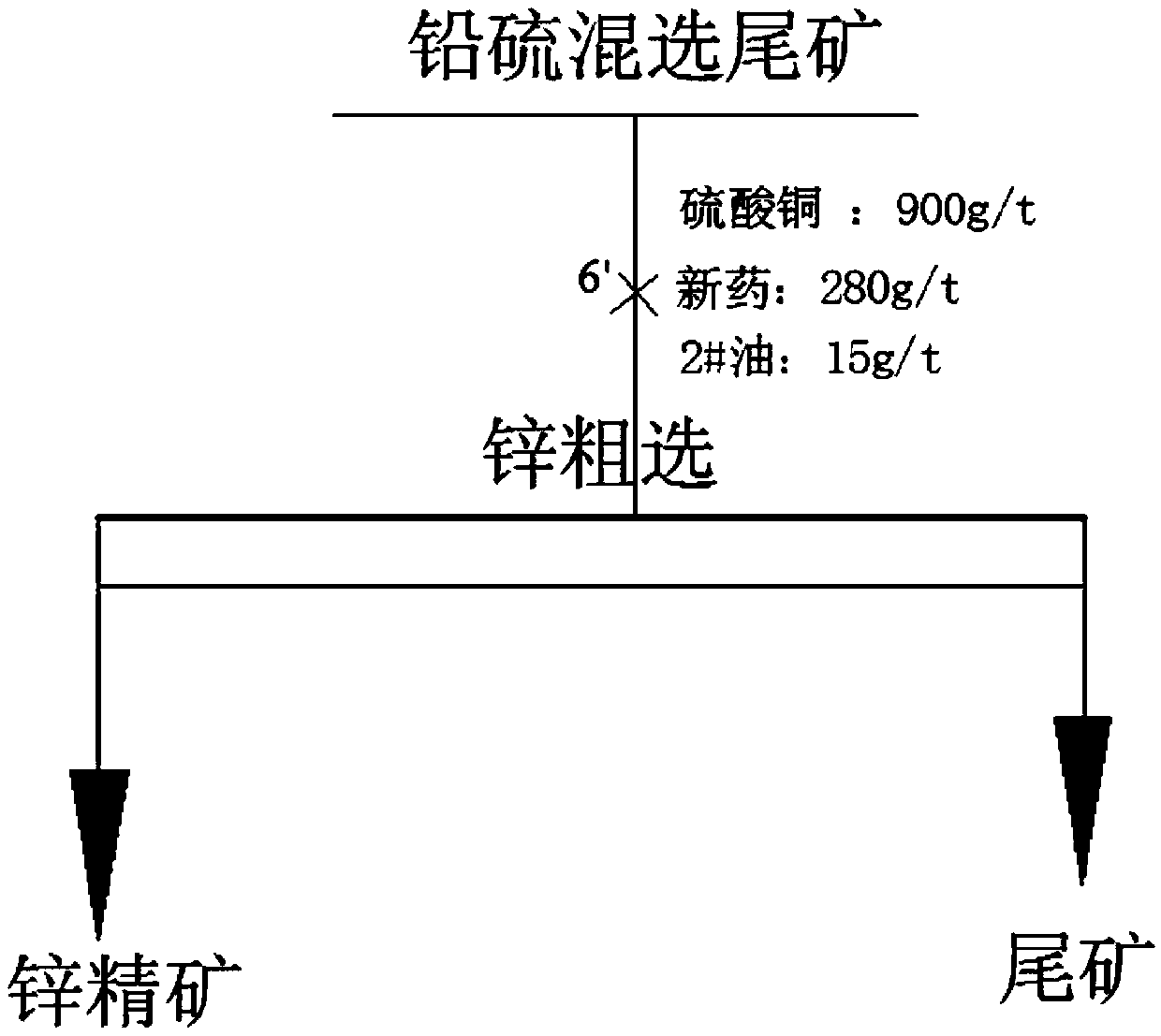

[0031] The example 1-4 technological process and condition of adopting collector of the present invention and conventional medicament see respectively figure 1 and figure 2 , embodiment 1-4 result comparison is shown in Table 1. It can be seen that, compared with conventional medicament conditions, its sphalerite recovery rate of the new medicament condition test of the present invention improves respectively by 2.57%, 1.49%, 2.31%, 2.21%, and the new medicament of the present invention can significantly improve sphalerite floating rate. The index is selected, and the dosage of medicine is small.

[0032] Table 1 Embodiment 1-4 Flotation index

[0033]

Embodiment 5~8

[0035] Examples 5-8 are lead-sulphur mixed tailings with different fineness (that is, different content less than 0.025 mm), which are used as raw ore for the condition test of the new agent, and the process flow is the same as above. Table 2 shows the comparison results of examples 5-8 using collectors of the present invention and conventional agents. It can be seen that, compared with conventional medicament conditions, its sphalerite recovery rate of the new medicament condition test of the present invention improves respectively by 1.15%, 2.71%, 2.69%, 2.80%, and the new medicament of the present invention can improve fine-grained sphalerite Ore flotation indicators, and the dosage of chemicals is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com