Lead silver residue flotation combined collector and application technology

A combination of collector and lead-silver slag technology, applied in flotation, solid separation, etc., can solve the problems of high cost, difficult mineral dissociation, energy consumption, etc., and achieve low production cost, wide application range and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

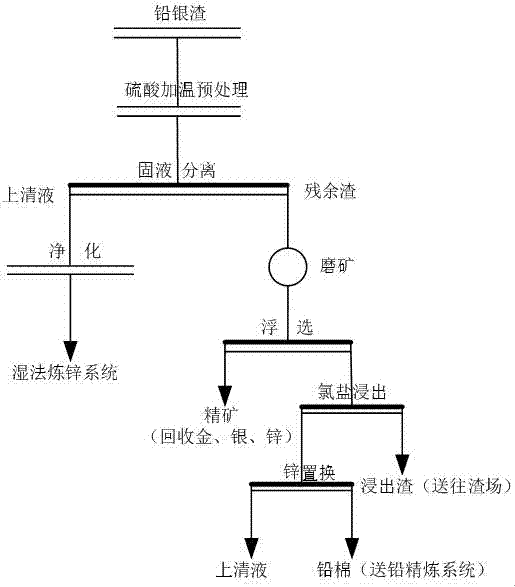

Image

Examples

Embodiment 1

[0022] 1. Sulfuric acid heating pretreatment of lead and silver slag: take lead and silver slag, which contains 145g / t of silver, 1.32g / t of gold, and 7.85g / t of zinc, stir and soak with the waste electrolyte produced by zinc hydrometallurgy, and add Concentrated sulfuric acid with a wt% of 98, an acidity of 150g / L, a liquid-solid ratio of 3:1, a temperature of 90°C, and a reaction time of 1.5h to separate solubles and residual residues, and the supernatant is purified and returned to the zinc hydrometallurgy system;

[0023] 2. Grinding process: Grinding the residual slag, the grinding fineness is 0.038mm, the grinding concentration is 55%, and the content accounts for 89.5%. During grinding, inhibitors are added to the ball mill, and the raw materials of the following weight components are: Made: 4 parts of sodium sulfide; 1 part of calcium oxide; 0.5 part of water glass, 2000g / t;

[0024] 3. Flotation pulp: the concentration of the flotation pulp obtained through the above...

Embodiment 2

[0027] 1. Sulfuric acid heating pretreatment of lead and silver slag: take lead and silver slag, which contains 291g / t of silver, 1.43g / t of gold, and 6.74% of zinc in the lead-containing silver slag, stir and soak with clear water as a solvent, and add 93wt% of Concentrated sulfuric acid with an acidity of 200g / L, a liquid-solid ratio of 4:1, a temperature of 95°C, and a reaction time of 2.5 hours to separate soluble matter and residual residue, and the supernatant is purified and returned to the zinc hydrometallurgy system;

[0028] 2. Grinding process: Grinding the residual slag, the grinding fineness is 0.038mm, the grinding concentration is 58%, and the content accounts for 91.4%. During grinding, inhibitors are added to the ball mill, and the raw materials of the following weight components are: Made: 6 parts of sodium sulfide; 2 parts of calcium oxide; 0.5 part of water glass, 4000g / t;

[0029] 3. Flotation pulp: the concentration of the flotation pulp obtained through ...

Embodiment 3

[0032] 1. Pretreatment of lead and silver slag with sulfuric acid heating: take lead and silver slag, which contains 178g / t of silver, 1.67g / t of gold, and 7.24% of zinc, stir and soak with the waste electrolyte produced by zinc hydrometallurgy, and add wt% 93 concentrated sulfuric acid with an acidity of 180g / L, a liquid-solid ratio of 2:1, a temperature of 90°C, and a reaction time of 4 hours to separate soluble matter and residual residue, and the supernatant is purified and returned to the zinc hydrometallurgy system;

[0033] 2. Grinding process: Grinding the residual slag, the grinding fineness is 0.038mm, the grinding concentration is 55%, and the content accounts for 90.5%. During grinding, inhibitors are added to the ball mill, and the raw materials of the following weight components are: Made: 5 parts of sodium sulfide; 2 parts of calcium oxide; 1 part of water glass, 2000g / t;

[0034] 3. Flotation pulp: the concentration of the flotation pulp obtained through the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com