Preparation method and application of composite magnetic nanomaterial based on nanoscale zero-valent iron

A technology of nano-zero-valent iron and composite magnetism, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of weak reducibility, large particles, and difficult storage, and achieve increased removal and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

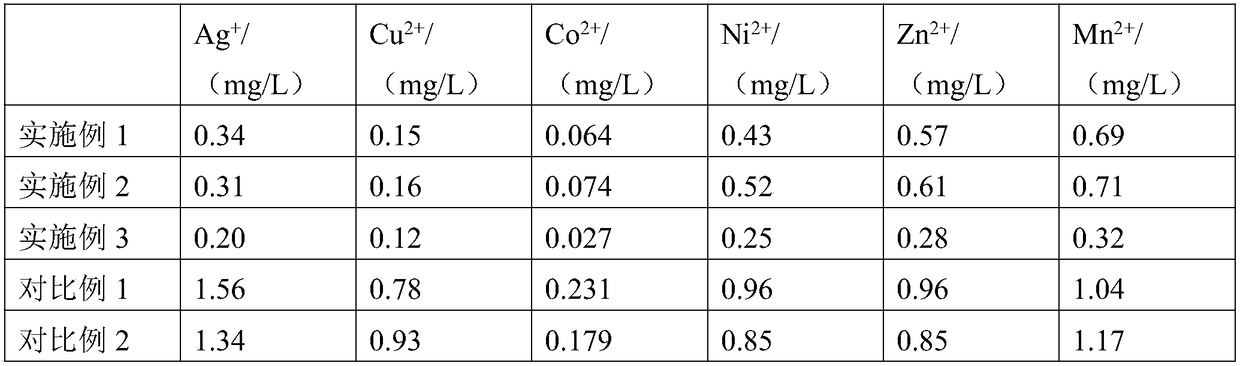

Examples

Embodiment 1

[0020] A preparation method based on nano zero-valent iron composite magnetic nanomaterials, the sewage treatment method comprises the following steps:

[0021] Step 1. Take 3 mass parts of nanometer zero-valent iron and join in the reaction container that 40 mass parts dehydrated alcohol, 15 mass parts acetonitrile are housed, then add 6 mass parts cetyltrimethylammonium bromide and 2 mass parts 1 part lecithin, 1 mass part 28wt.% ammonia water, and obtain a suspension after ultrasonication for 15 min.

[0022] Step 2. Under stirring conditions, add 8 parts by mass of ethanol solution dissolved in sodium oleate dropwise to the suspension prepared in step 1, and stir at room temperature for 30 minutes, wherein the mass ratio of sodium oleate to ethanol is 1:50 .

[0023] Step 3. Add 4 parts by mass of tetrabutyl titanate to the mixture in the above step 2. After ultrasonication at room temperature for 10 minutes, transfer the reaction solution into an autoclave, and react at ...

Embodiment 2

[0028] A preparation method based on nano zero-valent iron composite magnetic nanomaterials, the sewage treatment method comprises the following steps:

[0029] Step 1. Take 7 mass parts of nanometer zero-valent iron and join in the reaction container that 60 mass parts dehydrated alcohol, 20 mass parts of acetonitrile are housed, then add 15 mass parts cetyltrimethylammonium bromide, 4 mass parts 1 part lecithin and 3 parts by mass of 28wt.% ammonia water, the suspension was obtained after ultrasonication for 30 min.

[0030] Step 2. Under stirring conditions, add 17 parts by mass of ethanol solution dissolved with sodium oleate dropwise to the suspension prepared in step 1, and stir at room temperature for 45 minutes, wherein the mass ratio of sodium oleate to ethanol is 1:80 .

[0031] Step 3. Add 12 parts by mass of tetrabutyl titanate to the mixture in the above step 2. After ultrasonication at room temperature for 20 minutes, transfer the reaction solution into an autoc...

Embodiment 3

[0036] A preparation method based on nano zero-valent iron composite magnetic nanomaterials, the sewage treatment method comprises the following steps:

[0037] Step 1. Take 5 mass parts of nanometer zero-valent iron and join in the reaction vessel that 55 mass parts dehydrated alcohol, 16 mass parts of acetonitrile are housed, then add 9 mass parts cetyltrimethylammonium bromide and 3 mass parts 1 part of lecithin, 2 parts by mass of 28wt.% ammonia water, and a suspension was obtained after ultrasonication for 20 min.

[0038] Step 2. Under stirring conditions, add 10 parts by mass of ethanol solution dissolved in sodium oleate dropwise to the suspension prepared in step 1, and stir at room temperature for 40 minutes, wherein the mass ratio of sodium oleate to ethanol is 1:70 .

[0039] Step 3. Add 8 parts by mass of tetrabutyl titanate to the mixture in the above step 2, ultrasonicate at room temperature for 15 minutes, transfer the reaction solution into an autoclave, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com