Mineral flotation collecting agent for oxidized ores

A technology of mineral flotation and collector, applied in flotation, solid separation and other directions, can solve the problems of poor collection performance as oleic acid, energy consumption, rising cost, unacceptable to enterprises, etc., and achieve strong selective collection ability , The effect of enhanced selection ability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

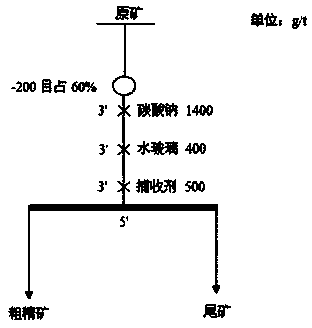

Image

Examples

Embodiment 1

[0026] Weigh the corresponding components according to the proportion, wherein: the weight percentage of dibutylammonium dithiophosphate is 1%, the weight percentage of sodium oleate is 30%, and the weight percentage of sodium edetate is Ratio is 21%, the weight percent distribution ratio of disodium maleate dihydrate is 10%, and the balance is water.

[0027] Firstly, mix dibutyl ammonium dithiophosphate, sodium oleate and part of water, heat to 60-80°C and stir for 0.5-1.5h to obtain component A, and ethylenediaminetetraacetic acid at 50-60°C Sodium and disodium maleate dihydrate are added to the remaining water and stirred for 2-4 hours to obtain component B, and the prepared component A is added to component B and stirred evenly to obtain the oxidized ore mineral flotation collector 1.

Embodiment 2

[0029] Weigh the corresponding components according to the proportion, wherein: the weight percentage of dibutylammonium dithiophosphate is 5%, the weight percentage of sodium oleate is 31%, and the weight percentage of sodium edetate Ratio is 25%, the weight percent distribution ratio of disodium maleate dihydrate is 10%, and the balance is water.

[0030] Firstly, mix dibutyl ammonium dithiophosphate, sodium oleate and part of water, heat to 60-80°C and stir for 0.5-1.5h to obtain component A, and ethylenediaminetetraacetic acid at 50-60°C Sodium and disodium maleate dihydrate are added to the remaining water and stirred for 2-4 hours to obtain component B, and the prepared component A is added to component B and stirred evenly to obtain the oxidized ore mineral flotation collector 2.

Embodiment 3

[0032] Weigh the corresponding components according to the proportion, wherein: the weight percentage proportion of dibutyl ammonium dithiophosphate is 10%, the weight percentage proportion of sodium oleate is 31%, the weight percentage proportion of sodium edetate Ratio is 25%, the weight percent distribution ratio of disodium maleate dihydrate is 15%, and the balance is water.

[0033] Firstly, mix dibutyl ammonium dithiophosphate, sodium oleate and part of water, heat to 60-80°C and stir for 0.5-1.5h to obtain component A, and ethylenediaminetetraacetic acid at 50-60°C Sodium and disodium maleate dihydrate are added to the remaining water and stirred for 2-4 hours to obtain component B, and the prepared component A is added to component B and stirred evenly to obtain the oxidized ore mineral flotation collector 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com